Method and device for detecting material level in material bin

A detection device and detection method technology, applied in the direction of measuring device, liquid level indicator for physical variable measurement, packaging, etc., can solve the problems of inability to detect continuous material level, high operating noise, complex structure, etc., and achieve fast calculation speed , High accuracy, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

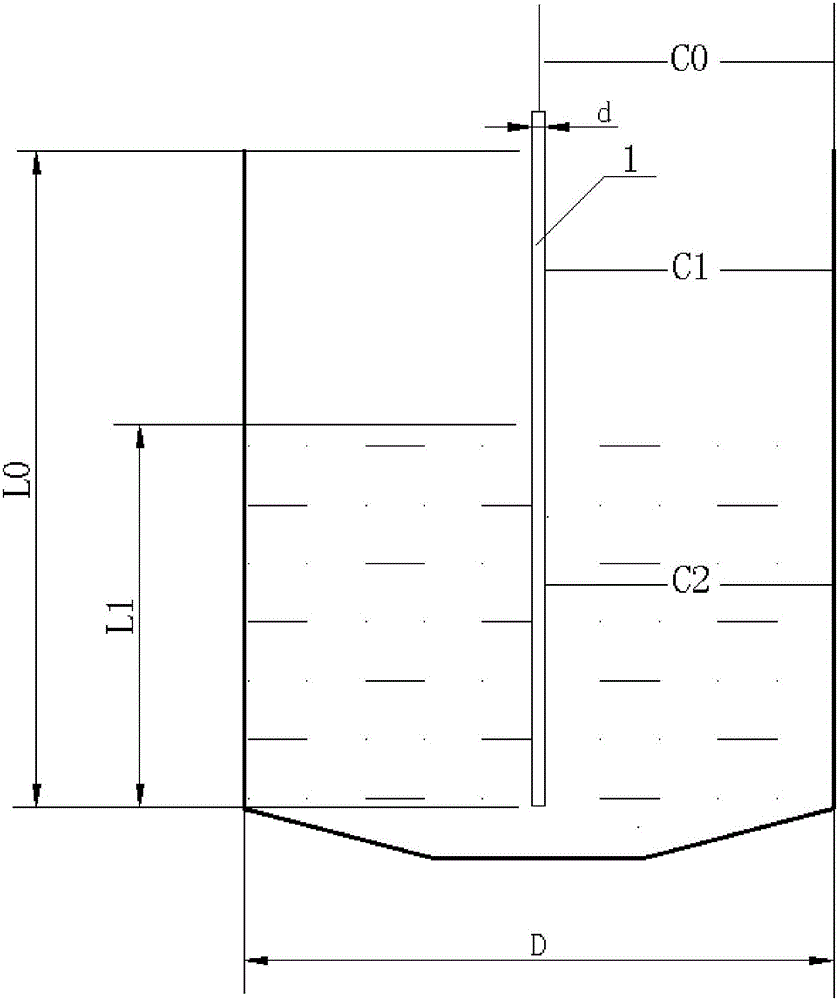

[0035] See Figure 1-Figure 3 , Image 6 , a method for detecting the height of a material level in a material bin, comprising the following steps:

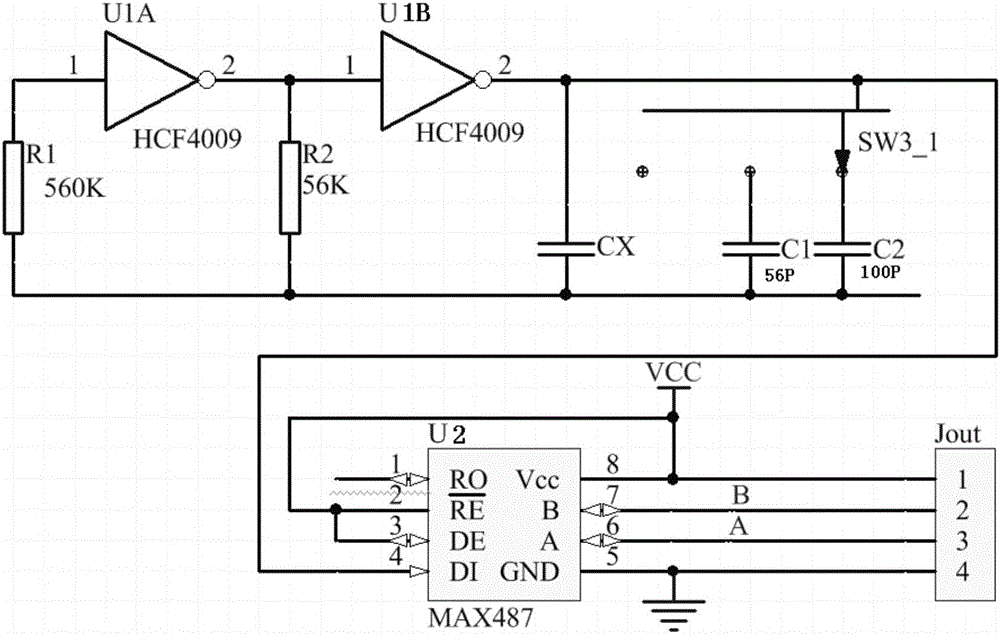

[0036] a. There is a measuring cable on the central axis of the circular metal material bin. The measuring cable is parallel to the metal bin wall and insulated from the metal bin wall. The measuring cable and the metal bin wall form a parallel plate capacitance. The parallel plate capacitance The capacitance is the total capacitance C of the capacitive sensor of the material bin X ;

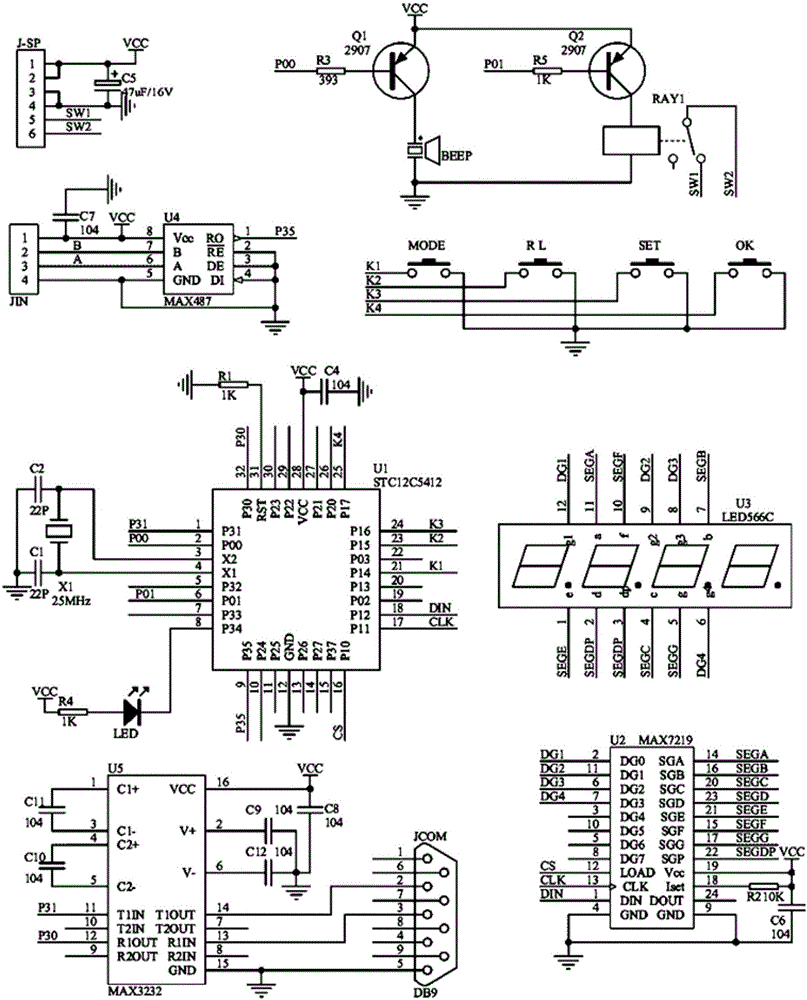

[0037] b Utilize the electronic oscillating circuit to form a primary instrument, use the RS-485 bus differential drive function to transmit pulse sequence signals between the primary instrument and the secondary ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com