Alternative increment type micro-displacement measurement sensor and measurement method

A technology of micro-displacement sensor and displacement sensor, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of unsatisfactory measurement accuracy and difficult improvement of measurement accuracy, and achieve reliable measurement, simple structure and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

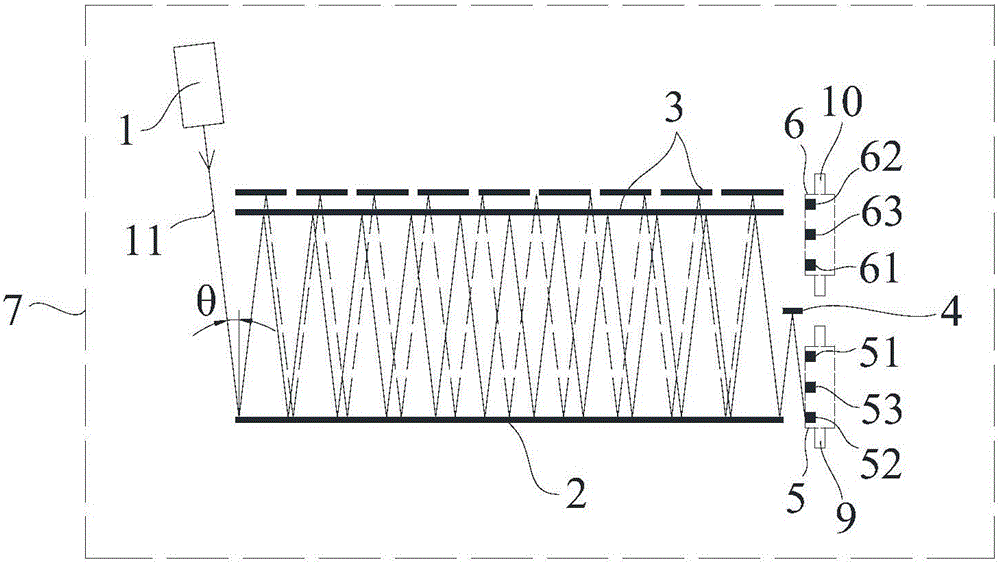

[0050] Such as Figure 1-3 As shown, a kind of alternating incremental measuring micro-displacement sensor of the present invention includes a laser beam 11, two mirrors, a photodetector 5, a photodetector 2 6, a guide rail 9, a guide rail 10 and a control processing system.

[0051] The photodetector one 5 is arranged on the guide rail one 9 and can move thereon, the photodetector two 6 is arranged on the guide rail two 10 and can move thereon, and the two reflecting mirrors Arranged in parallel and capable of relative movement, the first photodetector 5 and the second photodetector 6 are arranged at one end of the two reflecting mirrors, and the laser beam 11 is arranged at the opposite end, and the laser beam 11 is incident therein On one of the reflectors, after being alternately reflected by two reflectors, it is emitted to the first photodetector 5 or the second photodetector 6 and is sensed, and the control processing system communicates with the first photodetector 5...

Embodiment 2

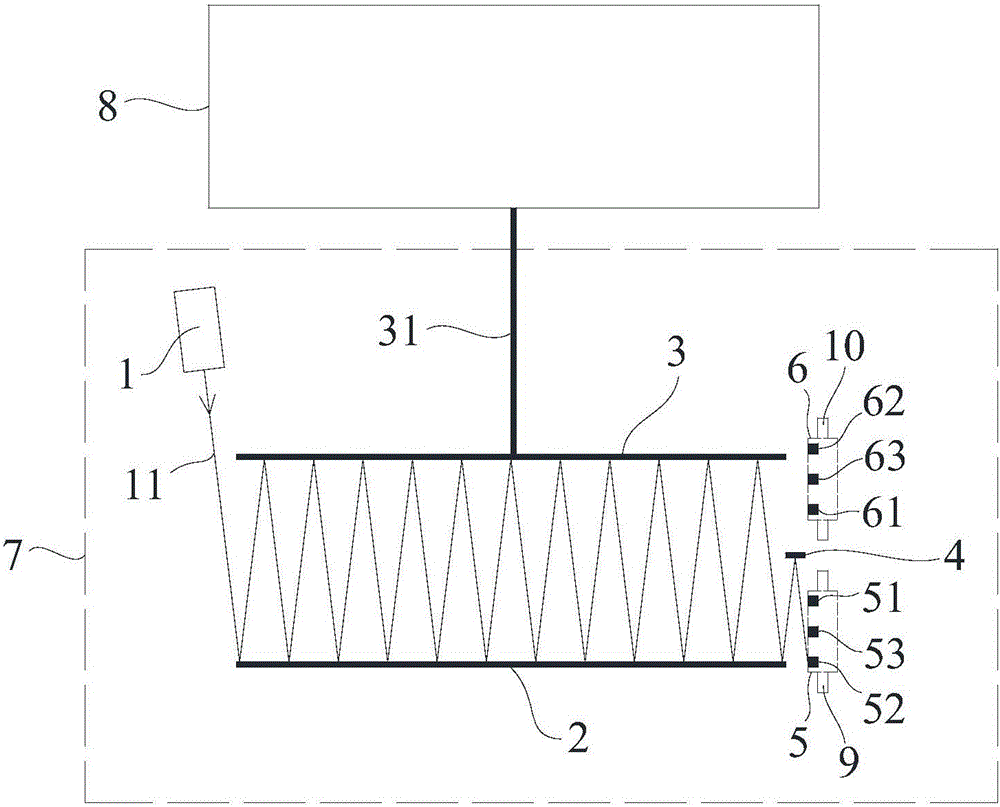

[0058] Such as Figure 1-3 As shown, a kind of alternate incremental measuring micro-displacement sensor of the present invention and measured object 8, described sensor comprises laser beam 11, fixed reflector 2, movable reflector 3, photodetector-5, photodetector Device II 6 and control processing system.

[0059] The object to be measured 8 is connected to the movable reflector 3 through a rigid member, and the photodetector one 5 is provided with a detection part 1 51, a detection part 2 52 and a detection part 3 53 at fixed intervals, and the detection part 3 53 is arranged at any position between the straight line connecting the detection part 1 51 and the detection part 2 52, and the photodetector 2 6 is provided with fixed-distance detection part 4 61, detection part 5 62 and detection part 6 63 , the detection part six 63 is arranged at any position between the straight line of the detection part four 61 and the detection part five 62, the fixed reflector 2 is arrang...

Embodiment 3

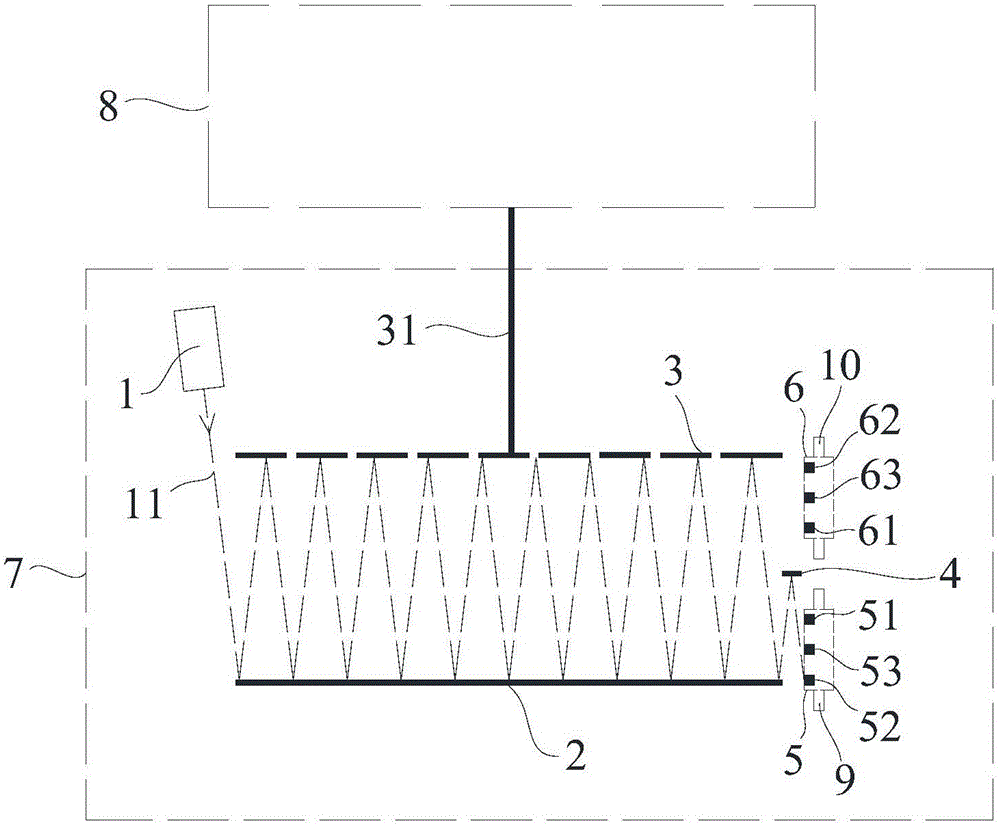

[0062] Such as Figure 1-3 As shown, an alternating incremental measuring micro-displacement sensor and a measured object 8 according to the present invention, the sensor includes a laser source 1, a laser beam 11, a fixed mirror 2, a moving mirror 3, and a detection mirror 4 , a photodetector one 5, a photodetector two 6 and a control processing system, and also includes a housing and a connector 31.

[0063]The laser beam 11 is obtained by emitting the laser source 1, and the laser source 1, the fixed reflector 2, the movable reflector 3, the detection reflector 4, the photodetector one 5 and the photodetector two 6 are all located in the housing , forming the reading head 7, the reading head 7 is provided with a mounting hole or a sticking piece, the moving mirror 3 is connected to the connecting piece 31, the connecting piece 31 is a rigid piece, and the connecting piece 31 protrudes from the The reading head 7 is externally connected to the measured object 8, and the pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com