Negative pressure reverse burning energy-saving furnace

An energy-saving furnace and negative pressure technology, applied in lighting and heating equipment, water heaters, fluid heaters, etc., can solve problems such as difficulty in forming a stable room temperature, manpower occupation, and difficulty in pressing fires, and achieve superior environmental performance and thermal efficiency The effect of improvement, work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

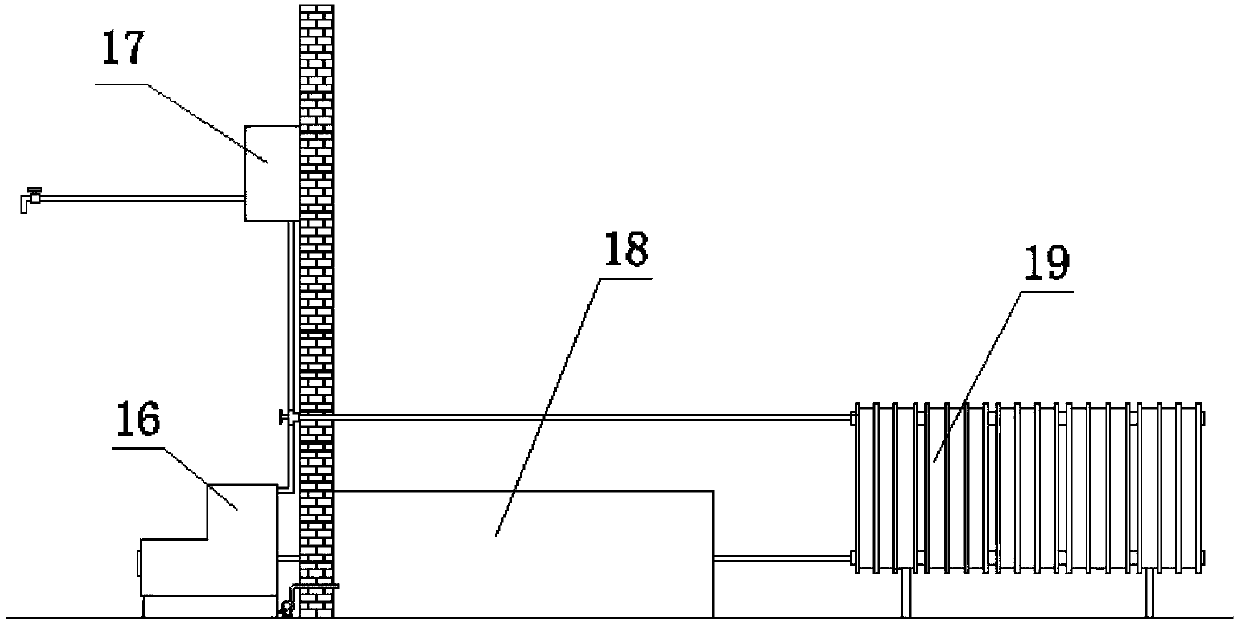

[0030] The general idea of the utility model is to provide a small-sized household stove, which adopts a closed furnace and a flue that turns back and forth repeatedly, and utilizes an induced draft fan to form a negative pressure exhaust smoke to support combustion. Introduce seven kinds of embodiments around this design below in conjunction with accompanying drawing:

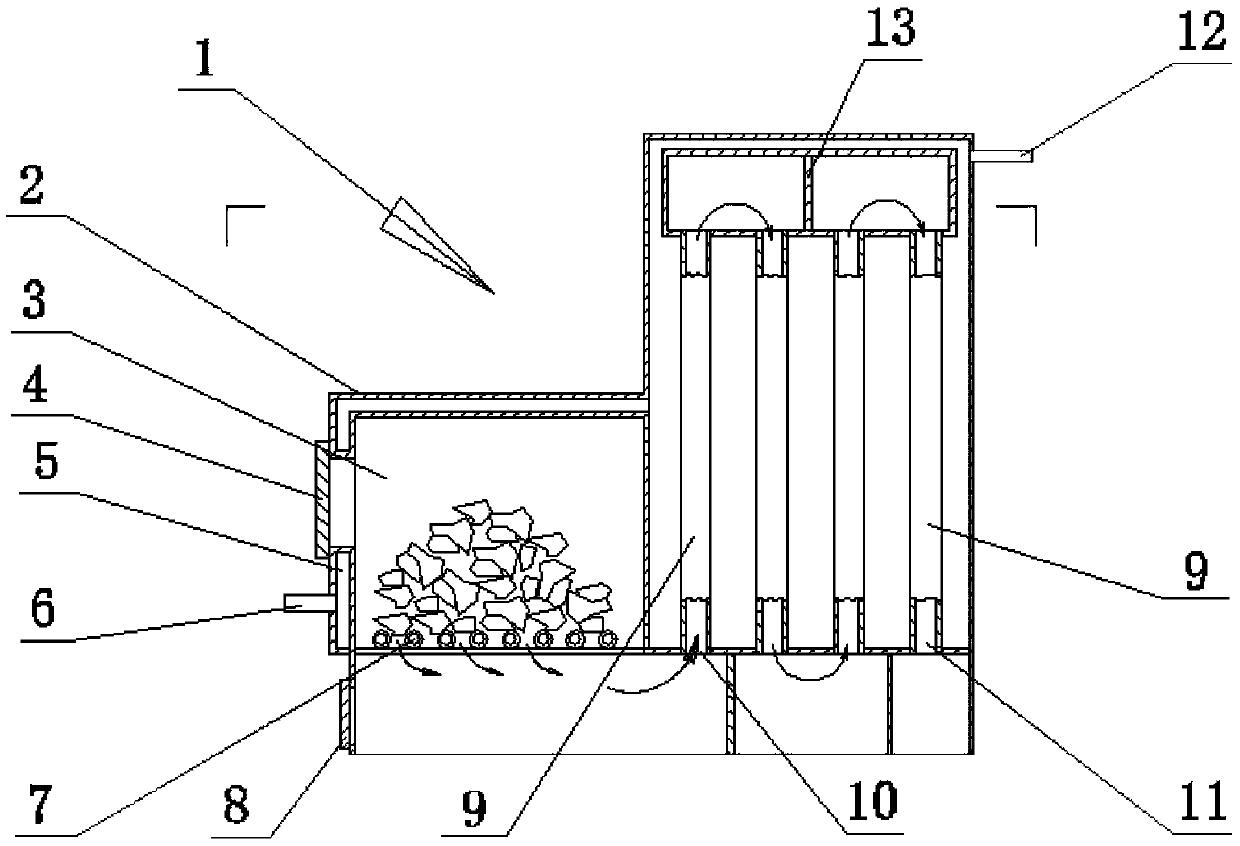

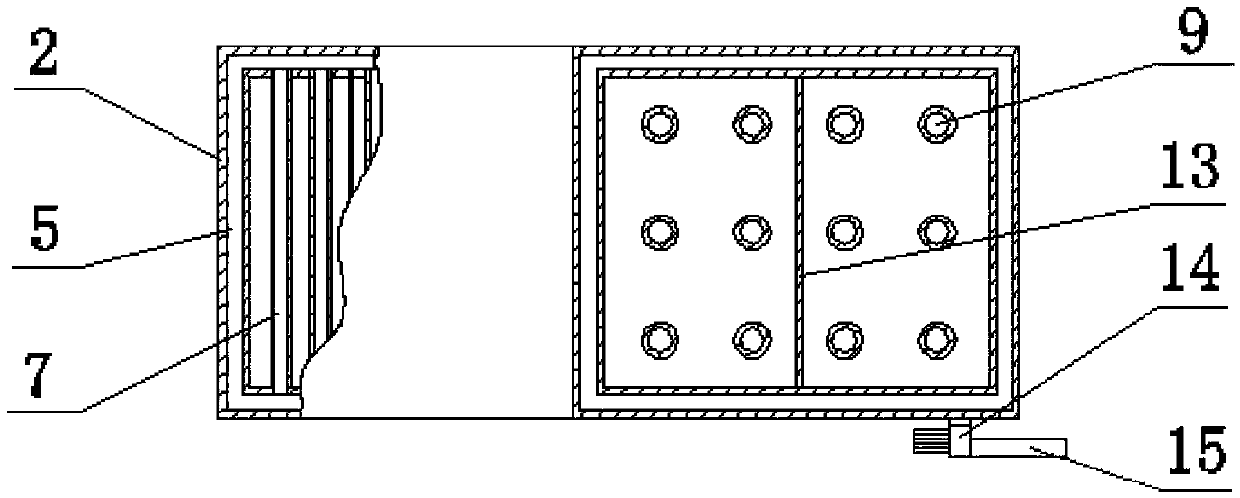

[0031] The first embodiment: as figure 1 , figure 2 As shown, this negative pressure reverse burning energy-saving furnace 1 is composed of shell 2, furnace 3, furnace door 4, water jacket 5, return pipe 6, fire grate 7, ash door 8, flue gas pipe 9 and other components. The hot water pipe 12 of 5 and the return pipe 6 are connected with the circulation pipes at both ends of the heater. Its characteristics mainly include two points: one is that the furnace is provided with a furnace door 4 that can be sealed and closed, and the structure of the furnace door 4 is not limited to the one shown in this figure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com