A soundproof fiberglass pipe

A technology of glass fiber reinforced plastic and glass fiber reinforced plastic, which is applied in the direction of thermal insulation protection of pipelines, pipeline protection, pipes, etc., can solve the problems that glass fiber reinforced plastic pipelines do not have thermal insulation, affect people's sleep, rest, pipeline thermal insulation protection, etc., and achieve complete functions. , The effect of suppressing noise and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

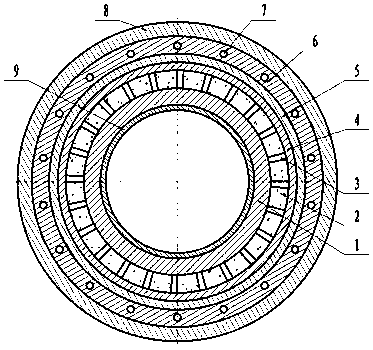

[0017] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a sound-insulating FRP pipe, including a FRP pipe body 1, a buffer layer 2, a buffer hole 3, a flexible layer 4, a sound-insulating layer 5, a filling layer 6, reinforcing ribs 7, and external protection layer 8 and an inner protective layer 9; the outer surface of the FRP main body 1 is fixedly connected with a buffer layer 2; the outer surface of the buffer layer 2 is fixedly connected with a flexible layer 4, and the inside of the buffer layer 2 is provided with several buffer holes 3 The outer surface of the flexible layer 4 is fixedly connected with a sound-insulating layer 5; the outer surface of the sound-insulating layer 5 is fixedly connected with a filling layer 6; the outer surface of the filling layer 6 is fixedly connected with an outer protective layer 8, and the inside of the filling layer 6 A number of reinforcing ribs 7 are arranged longitudinally; the outer su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com