split slips

A split type, slip technology, applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of poor clamping effect, inaccurate alignment of the first slip and the second slip, etc. , to achieve the effect of improving the clamping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

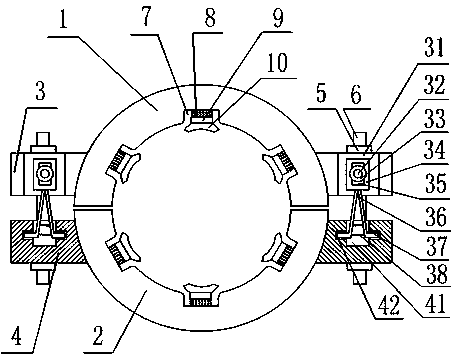

[0032] Such as figure 1 As shown, the split slips include a first slip 1 and a second slip 2, the first slip 1 is provided with a first fixing block 3, the second slip 2 is provided with a second fixing block 4, and the second slip 2 is provided with a second fixing block 4. The first fixed block 3 and the second fixed block 4 are provided with through holes for passing through the screw rod 6, and the first slip 1 and the second slip 2 form fastening slips through the cooperation of the screw rod 6 and the nut 5. The side wall of the first fixed block 3 is provided with a through groove 31, and the bottom of the through groove 31 is provided with a fixed rod 32, and the fixed rod 32 is provided with two fixed pieces 33, and the fixed rod 32 is arranged between the two fixed pieces 33 There is a connecting plate 34, the connecting plate 34 is provided with a perforation 35, the lower end of the connecting plate 34 is hinged with two connecting rods 36, the movable end of the c...

Embodiment 2

[0034] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the spring 38 is provided with two groups; the perforation 35 is circular or square; the fixing piece 33 is circular or square; The outer wall of 37 is set as a threaded surface; the axial through groove 7 is a rectangular groove; six axial through grooves 7 are uniformly arranged; the axial through groove 7 is connected with the first slip 1 and the second slip 2 arc transition; the clamping end surface of the clamping block 10 is set as an arc surface, and the arc of the arc surface is consistent with the arc of the first slip 1 and the second slip 2; the elastic structure 8 is a spring I .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com