Spherical pump cooling mechanism

A technology of cooling mechanism and spherical pump, which is applied in the direction of pumps, pump components, mechanical equipment, etc., can solve problems such as inability to cool friction pairs, high temperature of cylinder block inserts, failure of friction pairs, etc., and achieve low processing costs and high production efficiency. Good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

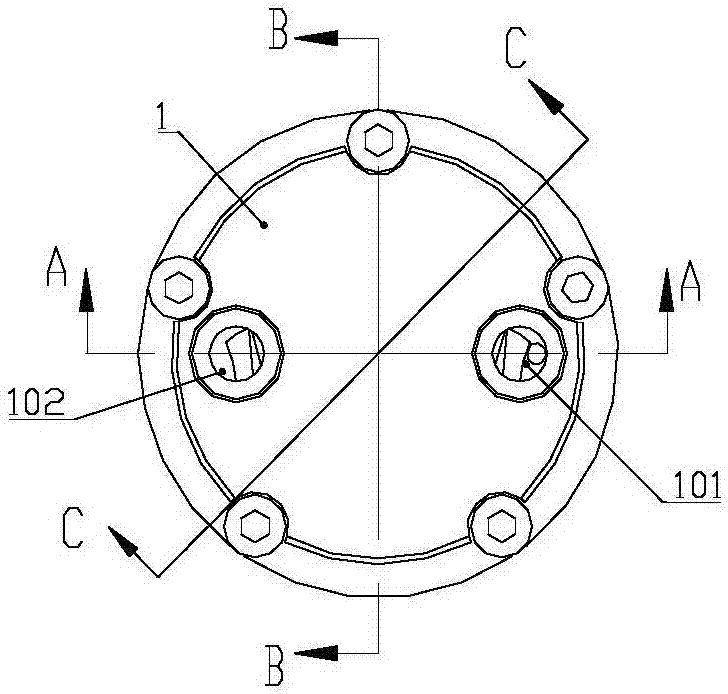

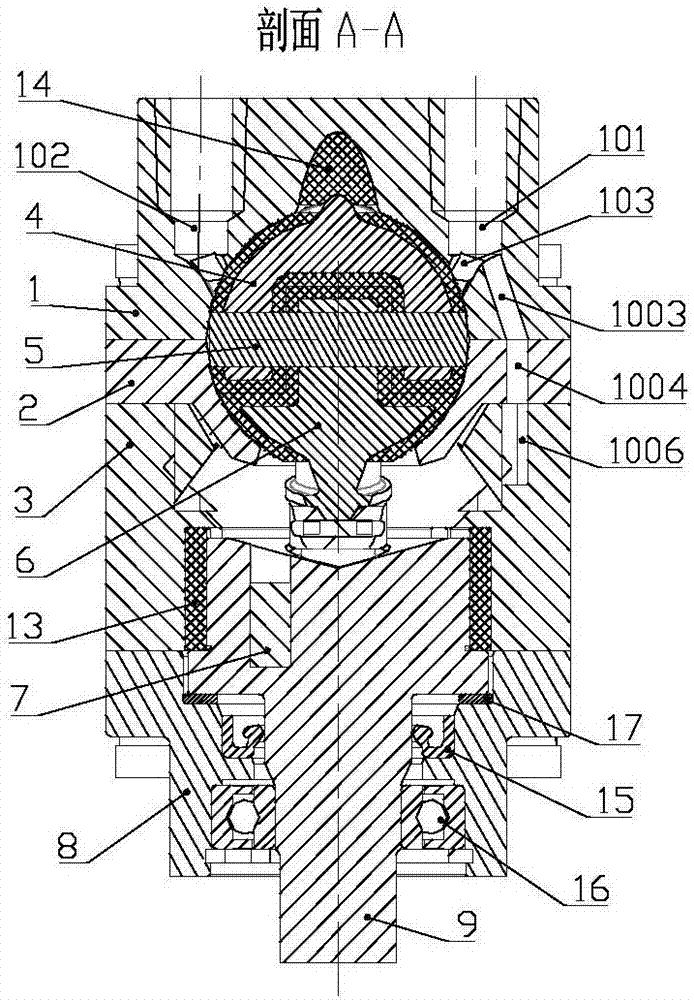

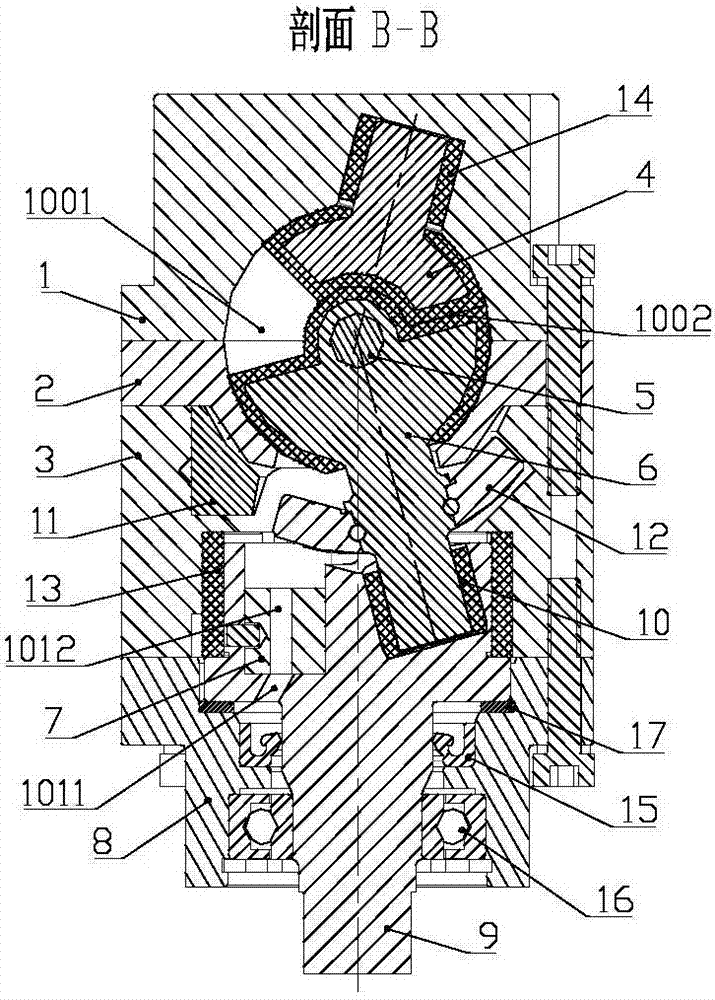

[0033] Such as figure 1 , image 3 , Figure 5 to Figure 8 , Figure 15 , Figure 16 , Figure 19 , Figure 20 As shown, the structure of the spherical compressor is the same as that of the conventional spherical compressor. The spherical pump includes a cylinder head 1, a cylinder body 2, a cylinder seat 3, a piston 4, a center pin 5, a turntable 6, a balance weight 7, a main shaft support 8, and a main shaft 9; The cylinder block 2 has a hemispherical inner spherical surface, a hemispherical lower spherical surface and a flange connected to the cylinder head 1. A through hole adapted to the working process of the turntable shaft is provided in the center of the lower part of the inner spherical surface of the cylinder body 2, that is, the turntable shaft hole; Five screw holes 107 and two pin holes 108 are respectively arranged on the cylinder block 2 and the cylinder head 1, and five corresponding threaded holes 109 and two pin holes 108 are respectively arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com