Hydrogen peroxide working fluid preheater

A working fluid and preheater technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as explosion and preheating temperature cannot be too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

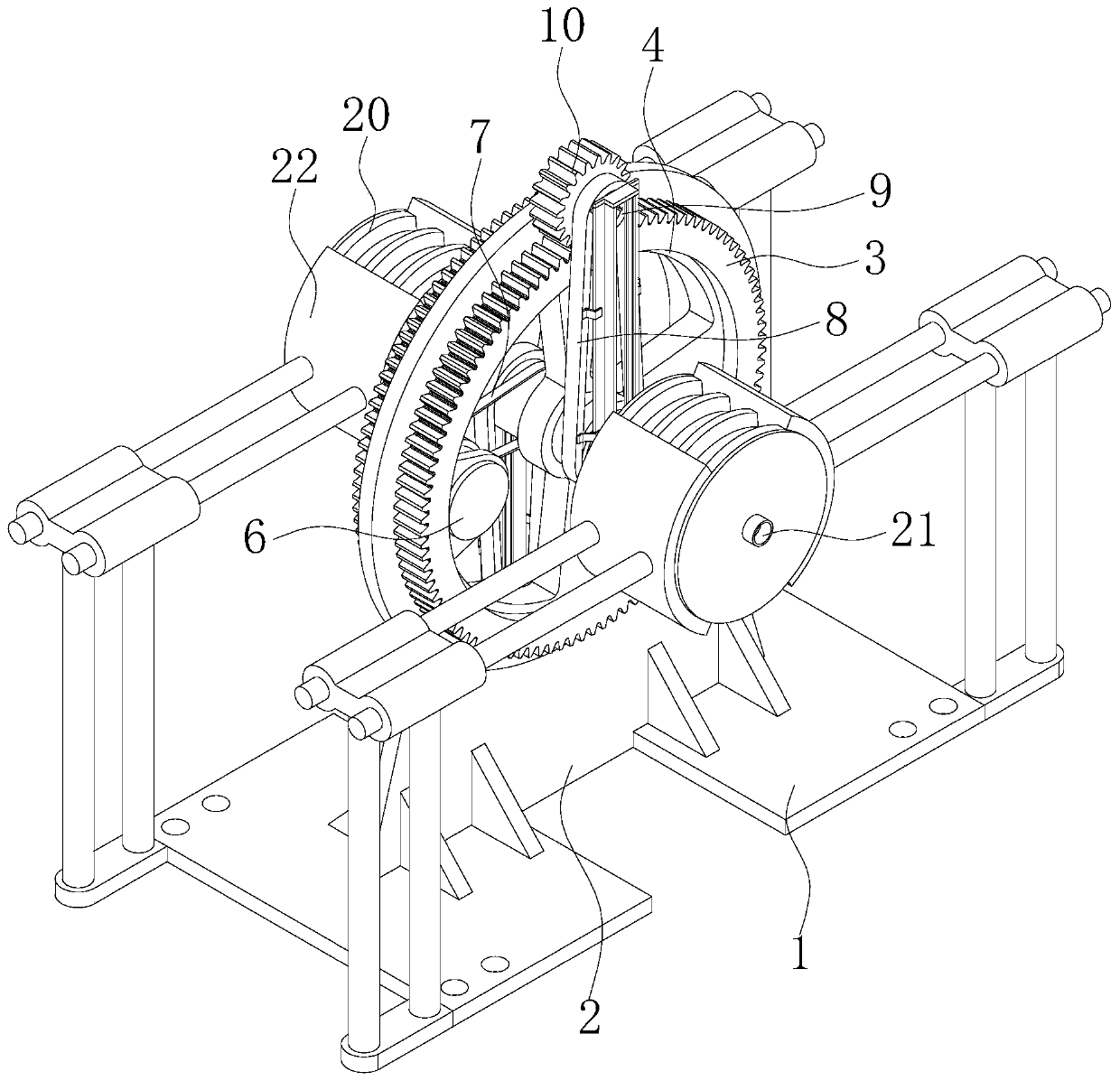

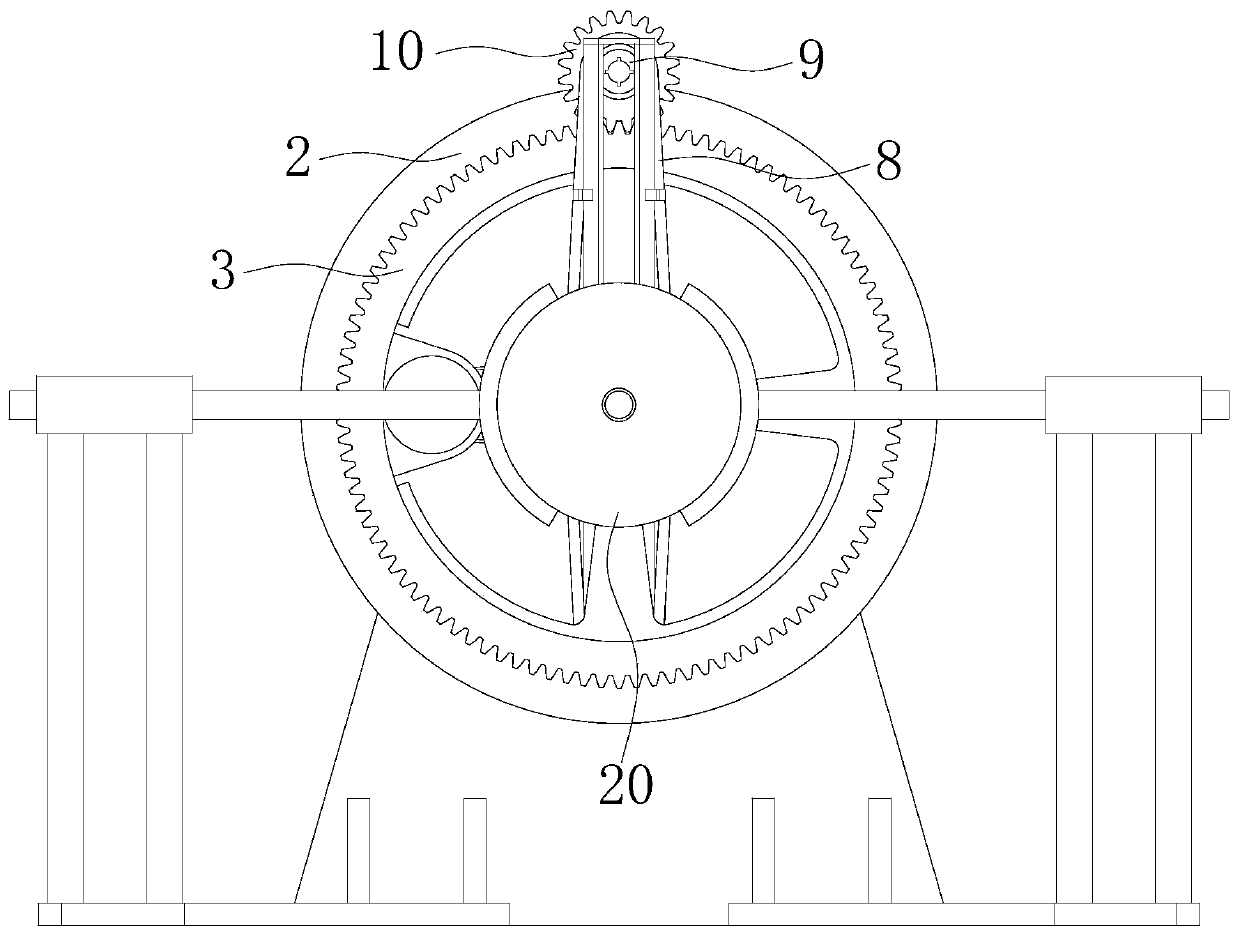

[0028] Such as Figure 1-9 As shown, a hydrogen peroxide working fluid preheater includes a base 1, a support plate 2 is fixedly installed on the upper surface of the base 1, and the end of the support plate 2 away from the base 1 is fixedly inserted with a large toothed ring 3, and the large toothed ring 3 There is an annular groove 23 in the middle of the circumferential surface, and the support plate 2 is clamped inside the annular groove 23 and the support plate 2 is fixedly connected with the annular groove 23. The annular groove 23 can divide the teeth of the large tooth ring 3 into two groups, front and rear. The inside of the large gear ring 3 is fixedly installed with a bracket 4, the center of the bracket 4 is plugged with a rotating shaft 5, the inner wall of the large gear ring 3 is fixedly installed with a motor 6, the output shaft of the motor 6 is connected to the rotating shaft 5 through a belt 7, and the motor The output shaft of 6 is fixedly equipped with pul...

Embodiment 2

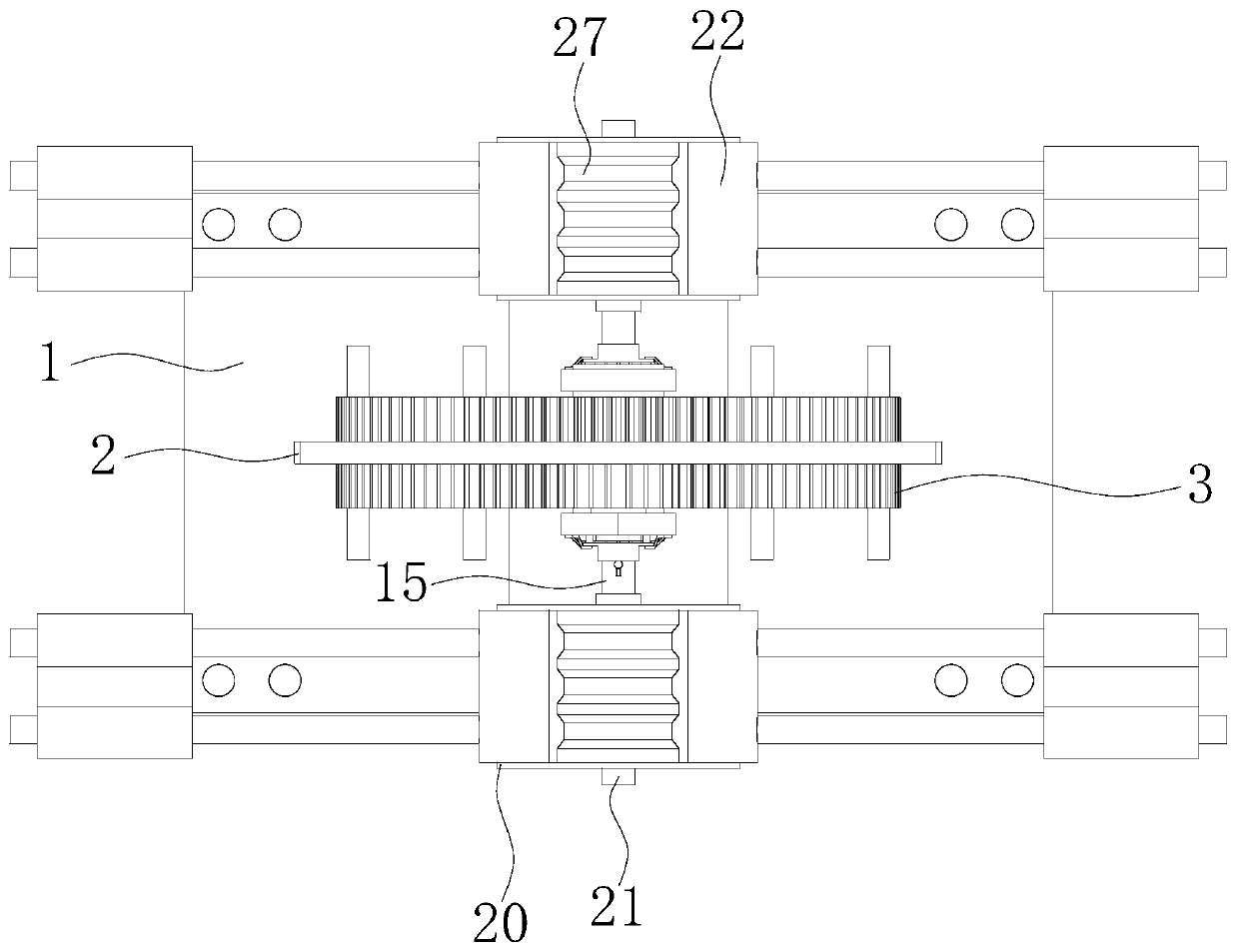

[0031] Such as Figure 5As shown, the heating device 22 includes two arc-shaped heating plates 2201 and two control sleeves 2202. The arc-shaped heating plates 2201 are electrically controlled heating plates with an arc-shaped structure. The two control sleeves 2202 are connected to the upper surface of the base 1. Fixed connection, two sliding rods 2203 are fixedly installed on the sides of the two arc-shaped heating plates 2201 away from each other. An electric push device is installed inside, which can adjust the displacement distance of the slide bar 2203. Two arc-shaped heating plates 2201 are clamped outside the preheating barrel 20. The inner walls of the arc-shaped heating plates 2201 are all uneven structures, arc-shaped The heating point of the heating plate 221 is located at the protruding point on the inner wall, and the uneven structure of the arc-shaped heating plate 2201 is clamped inside the trapezoidal groove 27 .

[0032] When in use, the motor 6 can drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com