800 MPa-level high-strength-tenacity steel plate used for engineering machine in extremely cold environment and manufacturing method for 800 MPa-level high-strength-tenacity steel plate

A technology for construction machinery and extreme cold environment, applied in the field of metal material manufacturing, it can solve the problems of low temperature toughness not being able to adapt to extreme cold environment, poor weldability, limited specifications of high-strength structural steel, etc. The effect of improving inclusion morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

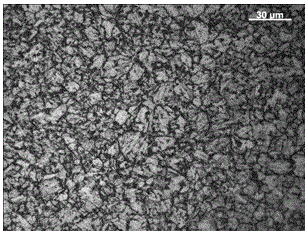

[0040] Embodiment 1: strictly according to the production process flow, the key parameters of the main process links are controlled as follows:

[0041] KR pretreatment: phosphorus content is 0.05%, sulfur content is 0.004%;

[0042] Converter top and bottom double blowing: the carbon content at the end of smelting is controlled to be 0.02% lower than the target value, and the phosphorus content is 0.005%;

[0043] LF refining outside the furnace: white slag desulfurization, soft blowing time is 9 minutes, Ca / AlS is 0.15, and the composition is fine-tuned;

[0044] Refining outside the RH furnace: the time for the vacuum degree ≤ 2.0mba is 18 minutes, the measured sulfur content is 0.002%, and the composition is fine-tuned;

[0045] Slab casting: control the fluctuation of the undercooling degree within the range of 15-25°C, the low magnification center segregation of the slab is 1.0 grade, no cracks and porosity, and the surface of the slab is inspected and treated; the smel...

Embodiment 2

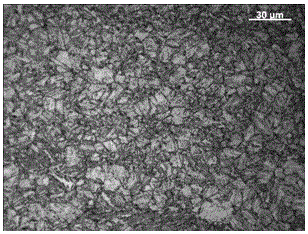

[0053] Embodiment 2: strictly according to the production process flow, the key parameters of the main process links are controlled as follows:

[0054] KR pretreatment: phosphorus content is 0.05%, sulfur content is 0.003%;

[0055] Converter top and bottom double blowing: the carbon content at the end of smelting is controlled by 0.02% lower than the target value, and the phosphorus content is 0.0055%;

[0056] LF refining outside the furnace: white slag desulfurization, soft blowing time is 10min, Ca / AlS is 0.18, and the composition is fine-tuned;

[0057] Refining outside the RH furnace: the time for the vacuum degree ≤ 2.0mba is 21 minutes, the measured sulfur content is 0.001%, and the composition is fine-tuned;

[0058] Slab casting: control the fluctuation of the undercooling degree within the range of 18-25°C, the low magnification center segregation of the slab is 0.5, without cracks and porosity, and the surface inspection and treatment of the slab are carried out;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com