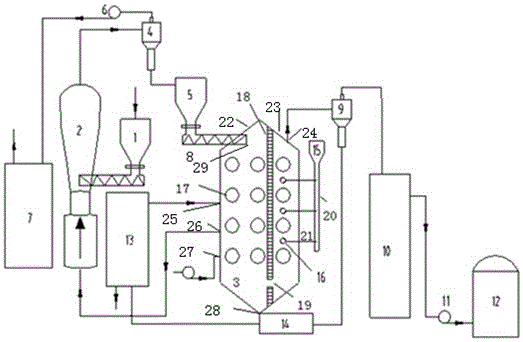

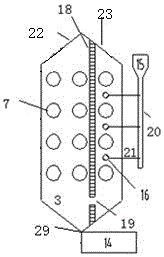

Biomass pyrolysis and catalytic cracking system

A biomass pyrolysis and catalytic cracking technology, applied in the field of biomass pyrolysis, can solve the problems of complex post-treatment process of bio-oil, difficult utilization and storage of bio-oil, complex components of bio-oil, etc. Construction cost and floor space, the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0071] Implementation case: use regenerative moving bed pyrolysis and catalytic cracking system to process pine wood chips. The basic data of raw materials are shown in Table 1.

[0072] Table 1: Basic data of pine wood chips

[0073]

[0074] Using this reaction system to process pine wood chips, the yield of gas products obtained is 68%, and the pyrolysis tar is almost completely cracked into gaseous products, with a high gas yield.

[0075] In the description of the present invention, it should be understood that the terms "first" and "second" are used for description purposes only, and cannot be interpreted as indicating or implying relative importance or implicitly indicating the quantity of indicated technical features. Thus, a feature defined as "first" and "second" may explicitly or implicitly include one or more of these features.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com