Matte finishing clear coat and preparation method thereof

A technology of clear topcoat and varnish, applied in the direction of coating, etc., can solve the problems of poor product storage stability, reduce the gloss of the paint film, increase light scattering, etc., achieve a good matte effect, high transparency of the paint film, and reduce the surface reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

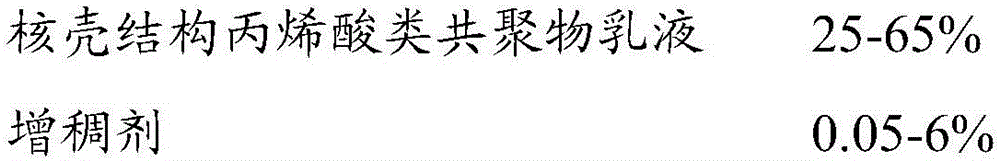

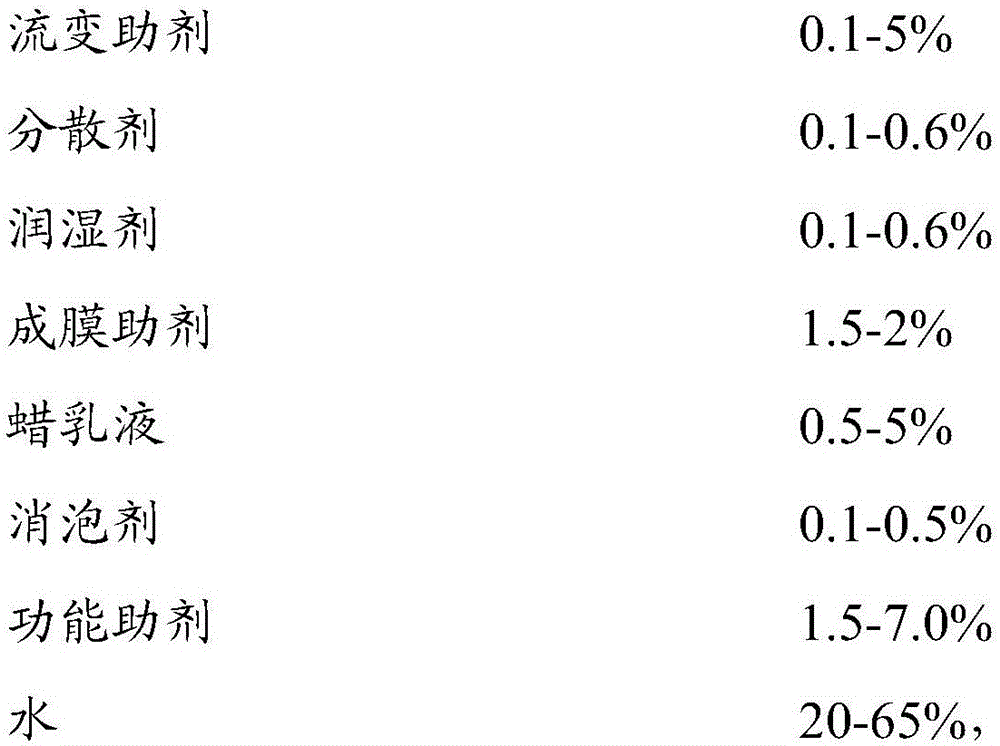

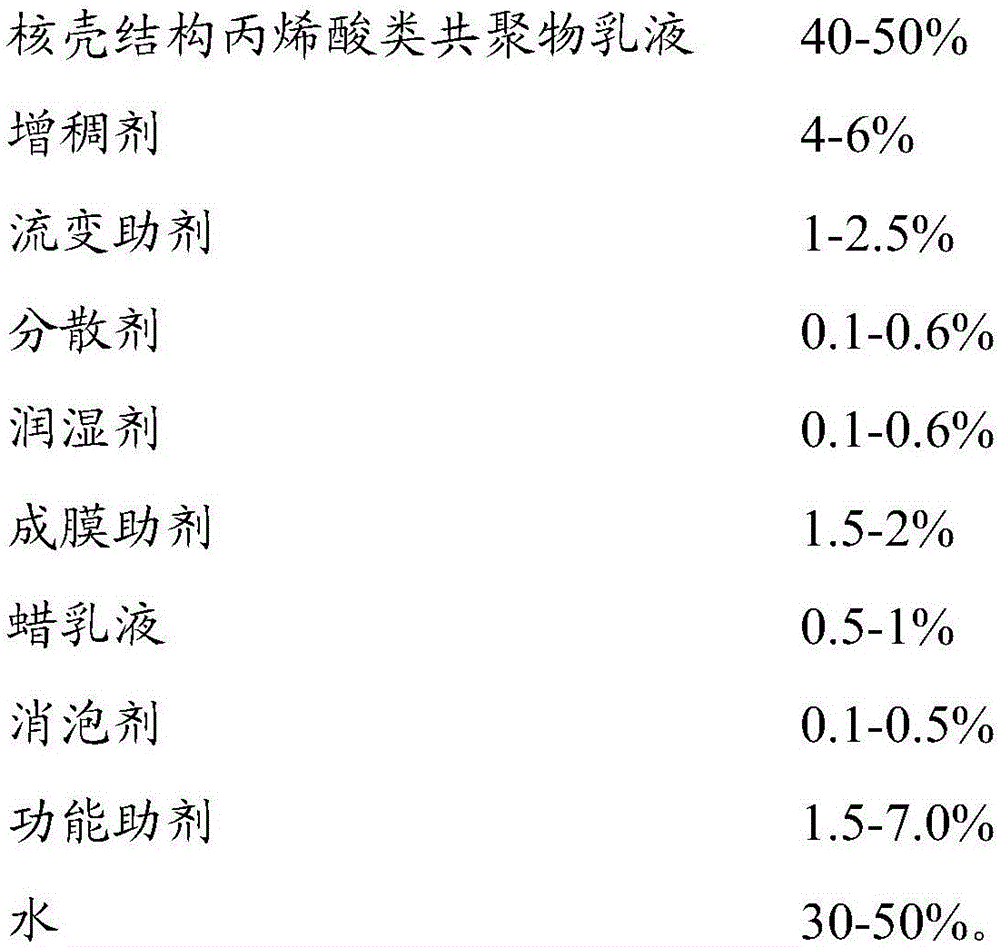

[0040] The three kinds of matte clear finish paints in this embodiment include the raw material components shown in Table 1 by weight percentage.

[0041] Table 1

[0042]

[0043] The preparation method of the above-mentioned modified hydroxyethyl cellulose aqueous solution is as follows: add water to the modified hydroxyethyl cellulose according to the stated mass concentration, disperse at a low speed for 20 minutes to prepare a pregel solution, and leave it overnight.

[0044] The preparation method of above-mentioned matte cover clear finish paint, comprises the steps:

[0045] Mix and stir the water and thickener for 5 minutes, add dispersant, wetting agent, defoamer, and film-forming aid in sequence, and mix and stir for 10 minutes; then add the core-shell structure acrylic copolymer emulsion and mix for 5 minutes, and finally mix the wax Emulsion, preservative, antifungal agent, antifreeze, pH regulator and rheological additive are added in sequence, and stirred fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com