Method for removing propamocarb in araliaceae saponin extract

A technology of extract and propamocarb, which is applied in the field of removing propamocarb in the saponin extract of Araliaceae plants, can solve the problems of low yield, high toxicity, and difficulty in opening the door to the international market, and achieve removal efficiency High, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

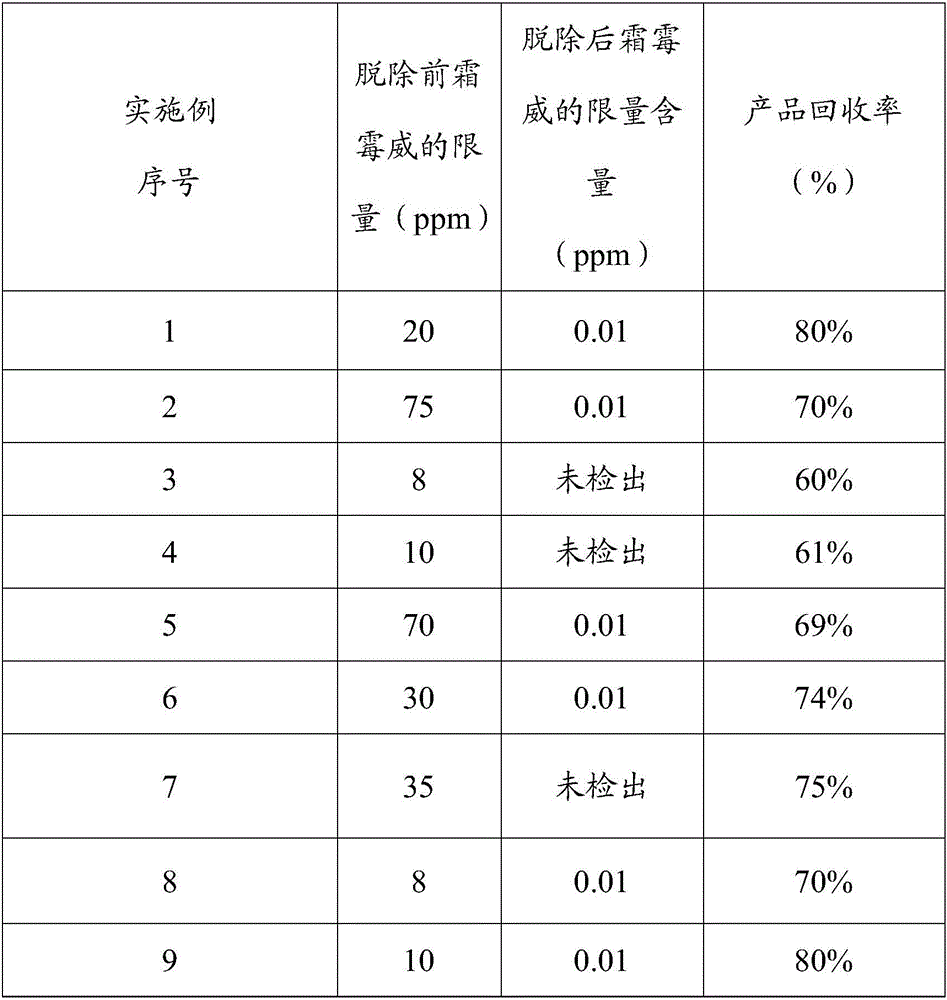

Embodiment 1

[0024] Take by weighing 50g ginsenoside extract samples (purchased in Ningbo Jin Ai Nong Biotechnology Co., Ltd.), dissolve completely with 2 times the amount of water, add 0.3% magnesium oxide powder of times the amount, settle after fully stirring, supernatant filter, remove most pesticide residues. Slowly add acetic acid test solution (aqueous solution with a mass fraction of acetic acid of 5%) to the supernatant, adjust the pH to 2-5, add 1 / 3 times the volume of acetone to extract the ginsenoside solution multiple times, the number of extractions is 3 times, organic Discard after concentrating and reclaiming the organic solvent, collect the mother liquor, which is the water phase, take the water phase and concentrate and spray dry to obtain the ginsenoside extract from propamocarb (saponin yield 80%).

Embodiment 2

[0026] Take by weighing 50g ginsenoside extract samples (purchased in Ningbo Jin Ai Nong Biotechnology Co., Ltd.), dissolve completely with 6 times the amount of water, add 0.3% magnesium oxide powder of times the amount, settle after fully stirring, supernatant filter, remove most pesticide residues. Slowly add acetic acid test solution (aqueous solution with a mass fraction of acetic acid of 5%) to the supernatant, adjust the pH to 2-5, add 1 / 3 times the volume of acetone to extract the ginsenoside solution multiple times, the number of extractions is 3 times, organic Discard after concentrating and reclaiming the organic solvent, collect the mother liquor, which is the water phase, take the water phase and concentrate and spray dry to obtain the ginsenoside extract from propamocarb (saponin yield 70%).

Embodiment 3

[0028] Take by weighing 50g ginsenoside extract samples (purchased in Ningbo Jin Ai Nong Biotechnology Co., Ltd.), dissolve completely with 2 times the amount of water, add 0.5% magnesium oxide powder of times the amount, settle after fully stirring, supernatant filter, remove most pesticide residues. Slowly add acetic acid test solution (aqueous solution with acetic acid mass fraction of 5%) to the supernatant, adjust the pH to 2-5, add 1 / 3 times the volume of acetone to extract the ginsenoside solution multiple times, the number of extractions is 4 times, organic Discard after concentrating and recovering the organic solvent, collect the mother liquor, which is the aqueous phase, take the aqueous phase and concentrate and spray dry to obtain the ginsenoside extract from propamocarb (saponin yield 60%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com