Fodder conveying device

A conveying device and feed technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problem of no powder material stirring and breaking up, and achieve high stirring force, high breaking efficiency, and increased stirring force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

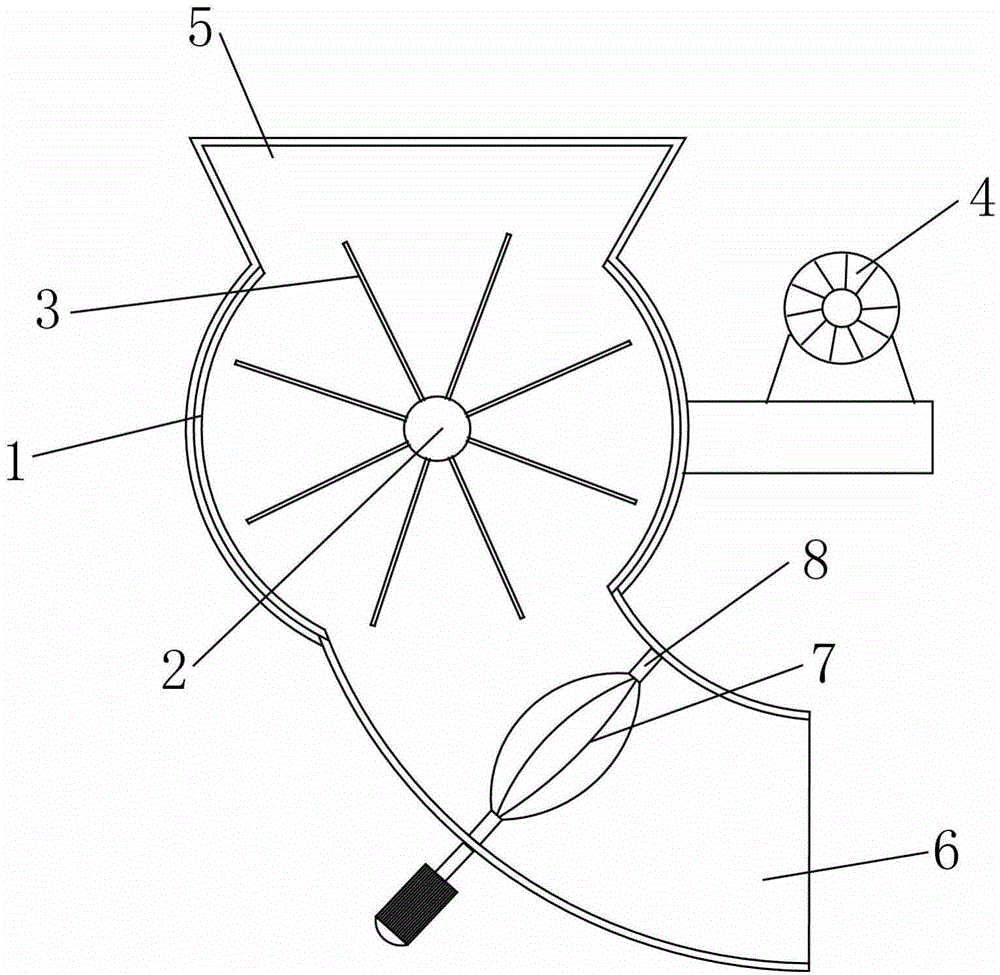

[0013] As shown in the figure, the feed conveying device includes a spherical casing 1, a rotating shaft 2, blades 3 and a driving device 4, the blades 3 are evenly distributed on the circumferential wall of the rotating shaft 2, and the rotating shaft 2 is horizontally mounted on the central axis of the casing 1 , the driving device 4 drives the rotating shaft 2 to rotate in one direction, the upper part of the casing 1 is provided with a feeding port 5, the bottom of the casing 1 is provided with a discharging port 6, and the inner wall of the discharging port 6 is provided with the direction of rotation and the direction of rotation of the rotating shaft Vertical stirring head7.

[0014] The rotation direction of the stirring head 7 is perpendicular to the rotation direction of the rotating shaft 2, and makes a tangential movement with the falling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com