a cutting machine

A cutting machine and cutting technology, which is applied in the cutting of textile materials, textile and papermaking, and fabric edge finishing, etc., can solve the problems of printing equipment not working properly, scrapping of printing equipment, unfavorable processing, etc., so as to facilitate rapid and effective cutting. Cut, Guaranteed Effectiveness, Uniform Gum Effect

Active Publication Date: 2019-10-01

安庆市嘉欣医疗用品科技股份有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when the cloth is actually cut, since the cloth is woven by spinning, when the cutting knife cuts the cloth, the incision where the cloth is cut is easy to come off the line, resulting in the slipping of the spinning during subsequent printing. The thread will wind the mechanical parts of the printing equipment and block them, causing the printing equipment to fail to work normally, or even directly causing the printing equipment to be scrapped, which is not conducive to processing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

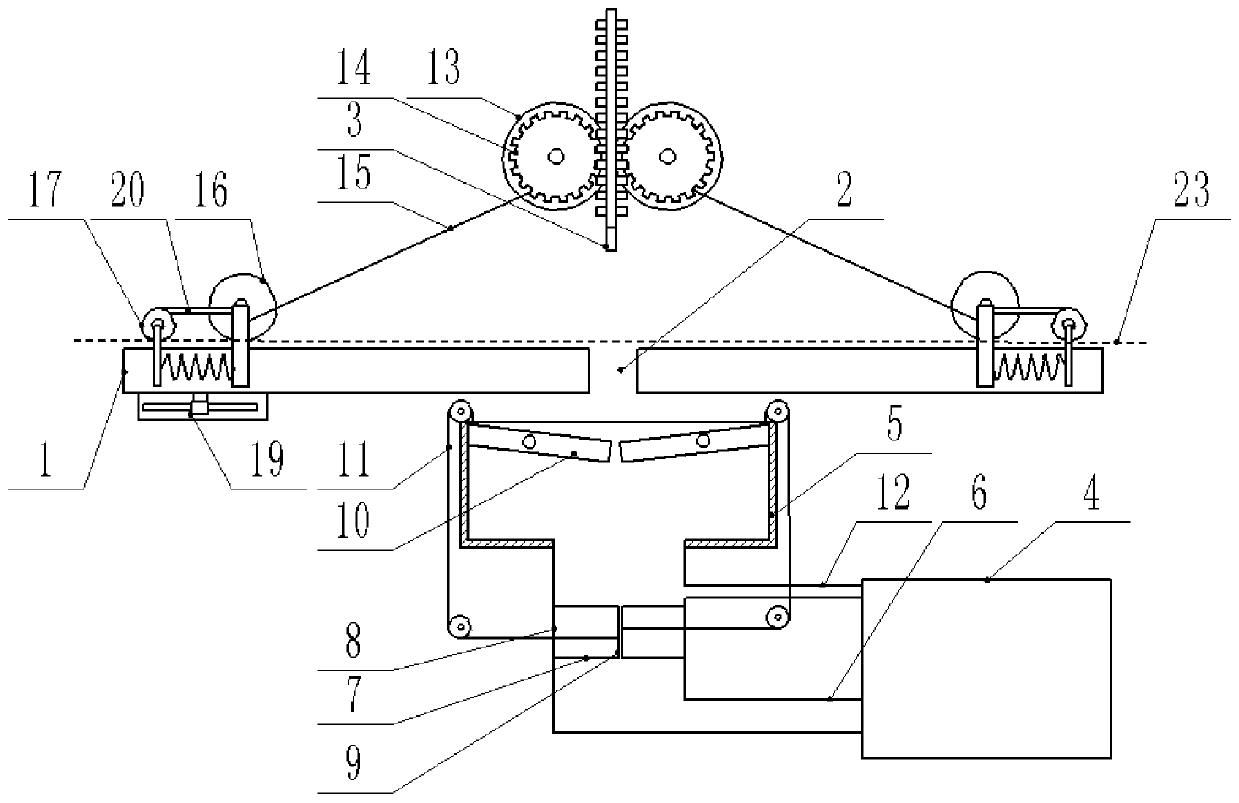

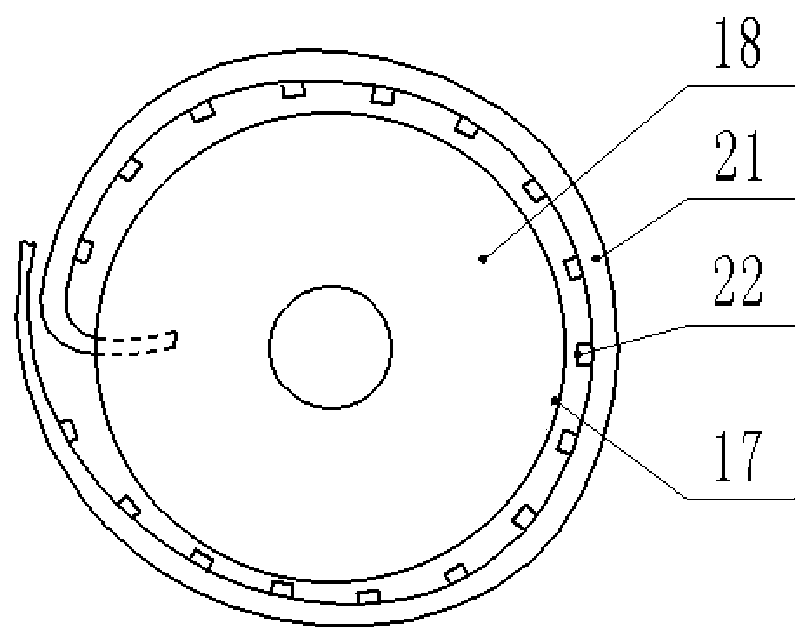

The invention relates to the technical field of printing fabric cutting, and discloses a cutting machine which comprises a cutting table. A cutting seam is formed in the cutting table, a cutting knifeis arranged above the cutting seam, a glue box is arranged on the lower side of the cutting table and connected with a glue inlet pipe, a telescopic block is arranged in the glue inlet pipe and provided with a fixed end and a telescopic end, the fixed end is fixed on the inner wall of the glue inlet pipe, a free end of the glue inlet pipe is connected with a glue groove, the glue groove is positioned below the cutting seam, an overturning plate is rotatably connected in the glue groove, one end of the overturning plate is positioned below the cutting seam, the other end of the overturning plate is connected with a drawing rope, a fixed pulley is arranged on the glue groove, a free end of the drawing rope strides the fixed pulley, sequentially penetrates the glue inlet pipe and the telescopic block and is connected at a telescopic end of the telescopic block, a return pipe is connected between the bottom of the glue groove and the glue box, and the diameter of the return pipe is smaller than that of the glue inlet pipe. According to the cutting machine, a spinning thread at a fabric cutting opening can be fixed, so that normal operation of a printing device cannot be affected by the loose spinning thread.

Description

technical field The invention relates to the technical field of cutting printed cloth, in particular to a cutting machine. Background technique In advertising printing, it is often necessary to print text on fabrics to make banners for the convenience of advertising. During the printing process of the banner, the cloth needs to be cut appropriately according to the length of the slogan. The existing cloth cutting machine includes a cutting table, on which a cutting seam is opened, by laying the cloth on the cutting table, the cloth is placed across the cutting seam, and the cutting knife is moved down through the cutting seam. The fabric is cut through the cutting seam, and the processing process is relatively simple. However, when the cloth is actually cut, since the cloth is woven by spinning, when the cutting knife cuts the cloth, the incision where the cloth is cut is easy to come off the line, resulting in the slipping of the spinning during subsequent printing. The ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06H7/00D06C25/00

Inventor 杨学智

Owner 安庆市嘉欣医疗用品科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com