Cooling device of food transportation equipment

A technology of transportation equipment and cooling device, which is applied in the field of machinery, can solve the problems of cumbersome operation, slow cooling speed of natural cooling method, and affecting food processing efficiency, so as to save cooling time, ensure stability, and improve food cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

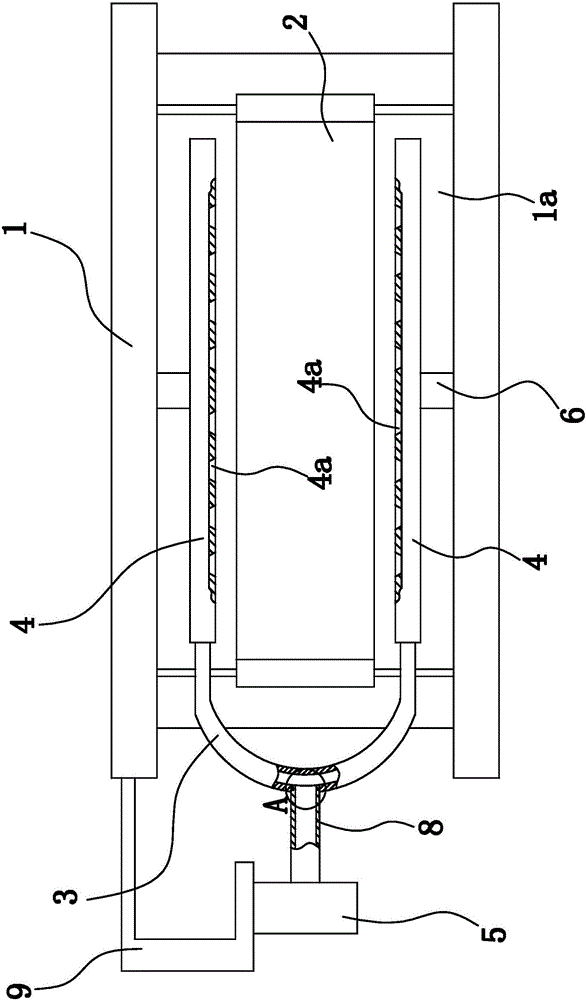

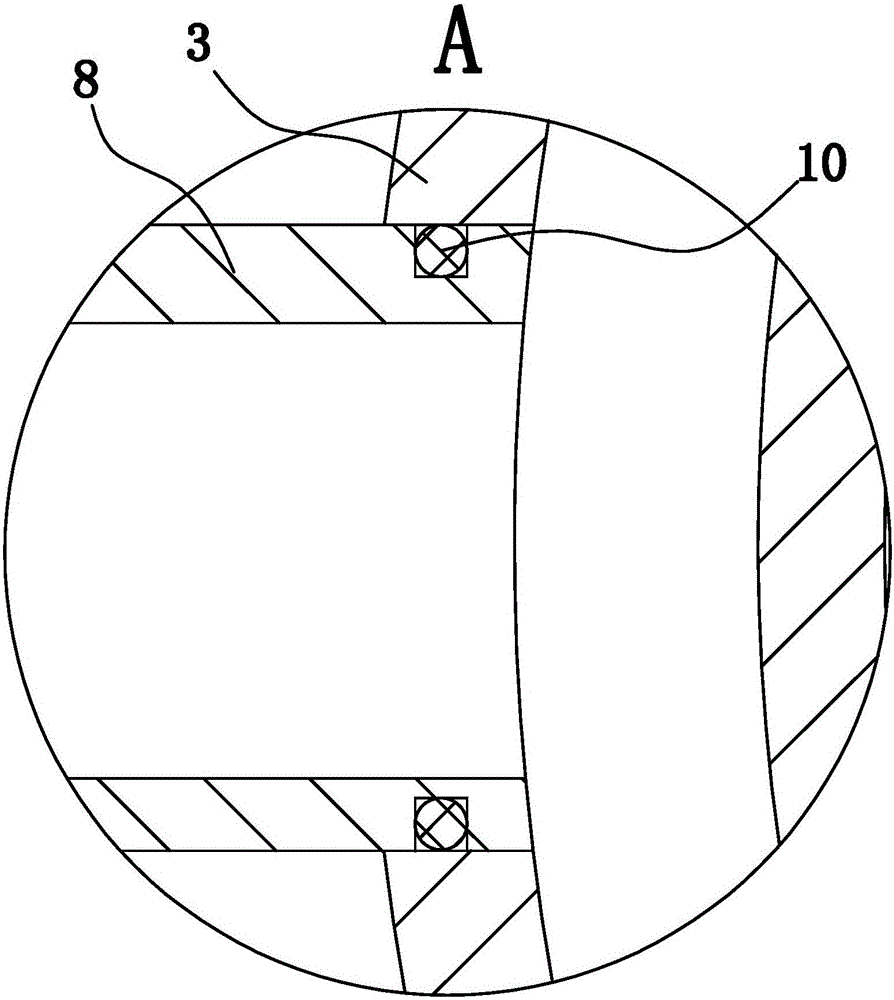

[0024] Such as figure 1 As shown, the food transportation equipment includes a support 1 with a conveying channel 1a, and a conveyor belt 2 is arranged in the conveying channel 1a, and the conveyor belt 2 is arranged along a horizontal direction. The cooling device of the food transportation equipment is composed of an air inlet pipe 3, an air outlet pipe 4, a blower fan 5 and the like.

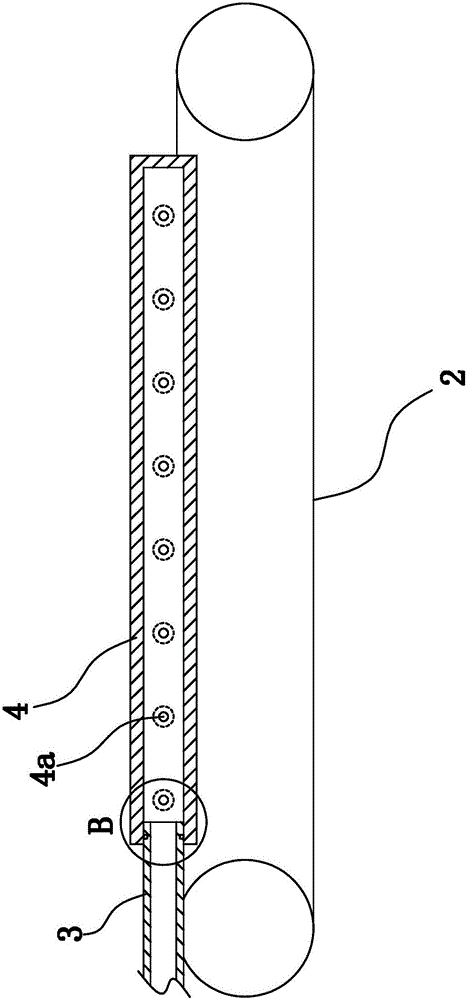

[0025] Wherein, there are two outlet pipes 4 and each outlet pipe 4 is straight. Each air outlet pipe 4 is fixed in the conveying channel 1a, and the two air outlet pipes 4 are located on both sides of the conveyer belt 2 respectively. Such as figure 1 As shown, the distribution direction of the two air outlet pipes 4 is perpendicular to the conveying direction of the conveyor belt 2 , and the axial extension direction of the air outlet pipes 4 is consistent with the conveying direction of the conveyor belt 2 . In this embodiment, the air outlet tube 4 is fixed to the bracket 1 throu...

Embodiment 2

[0030] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that the outer walls of both ends of the intake pipe 3 have ring-shaped sealing parts, and the end faces of the two sealing parts are respectively connected to the corresponding openings. The end faces meet. An annular sealing groove is provided on the end surface of the sealing part, and an annular sealing gasket is arranged in the sealing groove, and the two end surfaces of the annular sealing gasket respectively abut against the bottom wall of the sealing groove and the end surface of the opening end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com