Method for injection molding on metal shell, manufacturing method for metal shell of notebook computer and metal shell

A technology for notebook computers and metal shells, applied in the direction of metal shells, etc., can solve the problems of cracked surface unevenness, metal shells are not tightly combined, and unequal, and achieve the effects of small plastic deformation, prevention of plastic deformation, and good surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

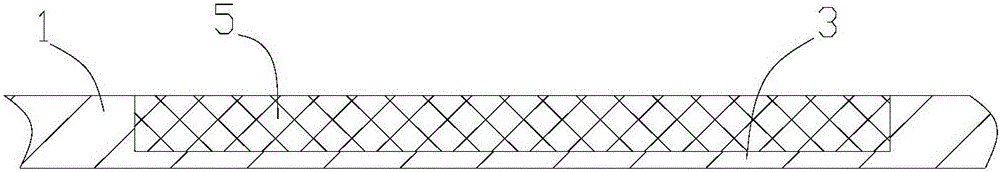

[0034] The embodiment of the present invention discloses a method of injection molding on the metal casing. The manufacturing method can reduce the plastic deformation of the plastic 5 after injection molding, and further increase the bonding ability of the plastic 5 and the metal casing 1 . The manufacturing method includes the following steps:

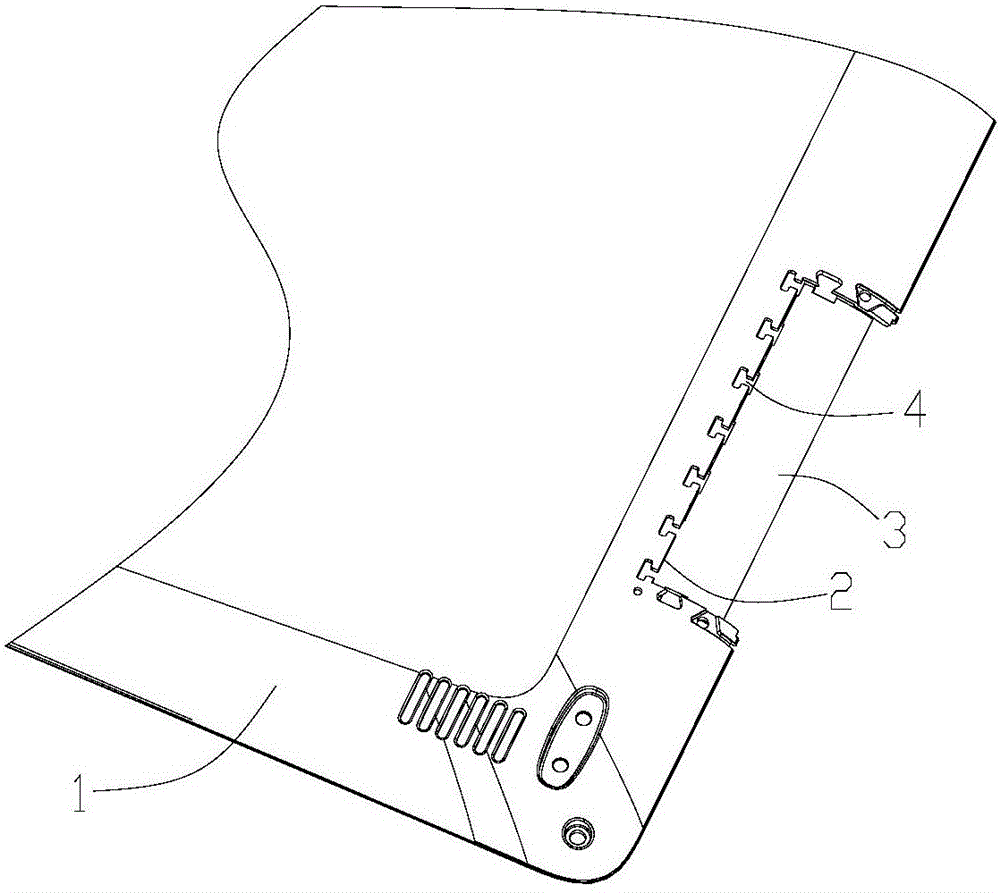

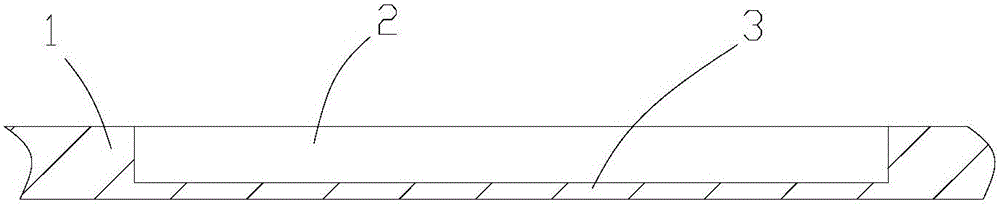

[0035] S1: if figure 1 and figure 2 As shown, a sinker 2 is formed on the outer surface of the metal shell 1 and the inner surface thereof, and a reserved thin wall 3 is formed between the bottom of the sinker 2 and the inner surface.

[0036] Since the metal casing 1 has a signal shielding effect on the antenna of the notebook computer, it is necessary to arrange a plastic 5 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com