Cross-shaped axle type automatic universal drilling device

A drilling device and cross shaft technology, applied in positioning devices, clamping devices, boring/drilling and other directions, can solve the problems of worker injury, low efficiency and high temperature, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

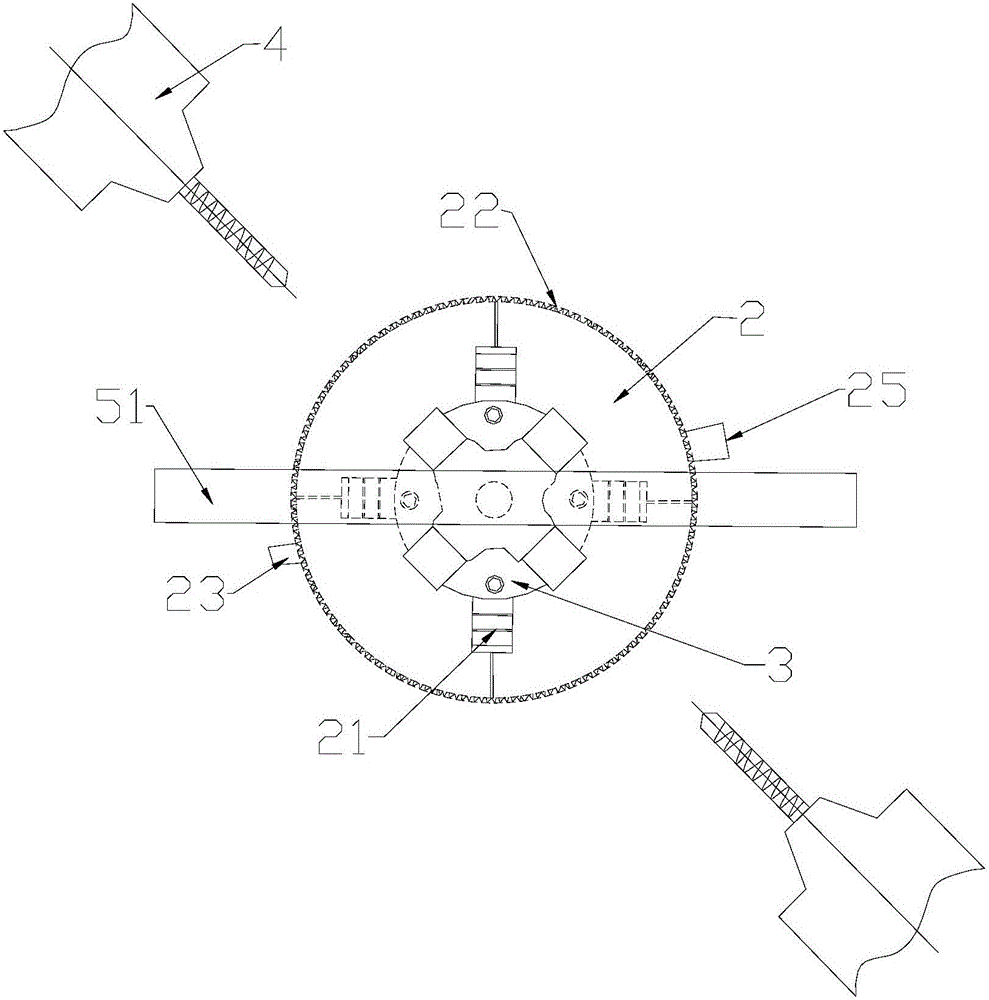

[0018] refer to figure 1 , figure 2 and image 3 , a cross-axis type universal automatic drilling device of the present invention, comprising a processing table 1, a four-jaw chuck 2 flexibly connected to the processing table 1, several main motors 4, and several drill bits 41 connected to the main motor 4 , it is characterized in that: the processing table 1 is also provided with a support 51, the center of the cross bar of the support 51 is provided with a hydraulic cylinder 52, the hydraulic cylinder 52 is connected to the pressure head 5, and the pressure head 5 is below the The four-jaw chuck 2, the four jaws 21 on the four-jaw chuck 2 are all connected with the limit block 3, and the circumference of the four-jaw chuck 2 is provided with straight teeth 22. The straight teeth 22 are connected with the gear drive mechanism 23, the four-jaw chuck 2 is provided with a square hole 24 on its circumference, and the auxiliary motor 25 is connected to the square hole 24, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com