A device for separating solid polymers from mixed emulsions

A technology for separating solid polymers, which is applied in the field of equipment for separating solid polymers from mixed emulsions. It can solve problems such as difficult recycling, pipeline loss, and cumbersome process operations, so as to save reaction cycles and quickly recycle. , The effect of shortening the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

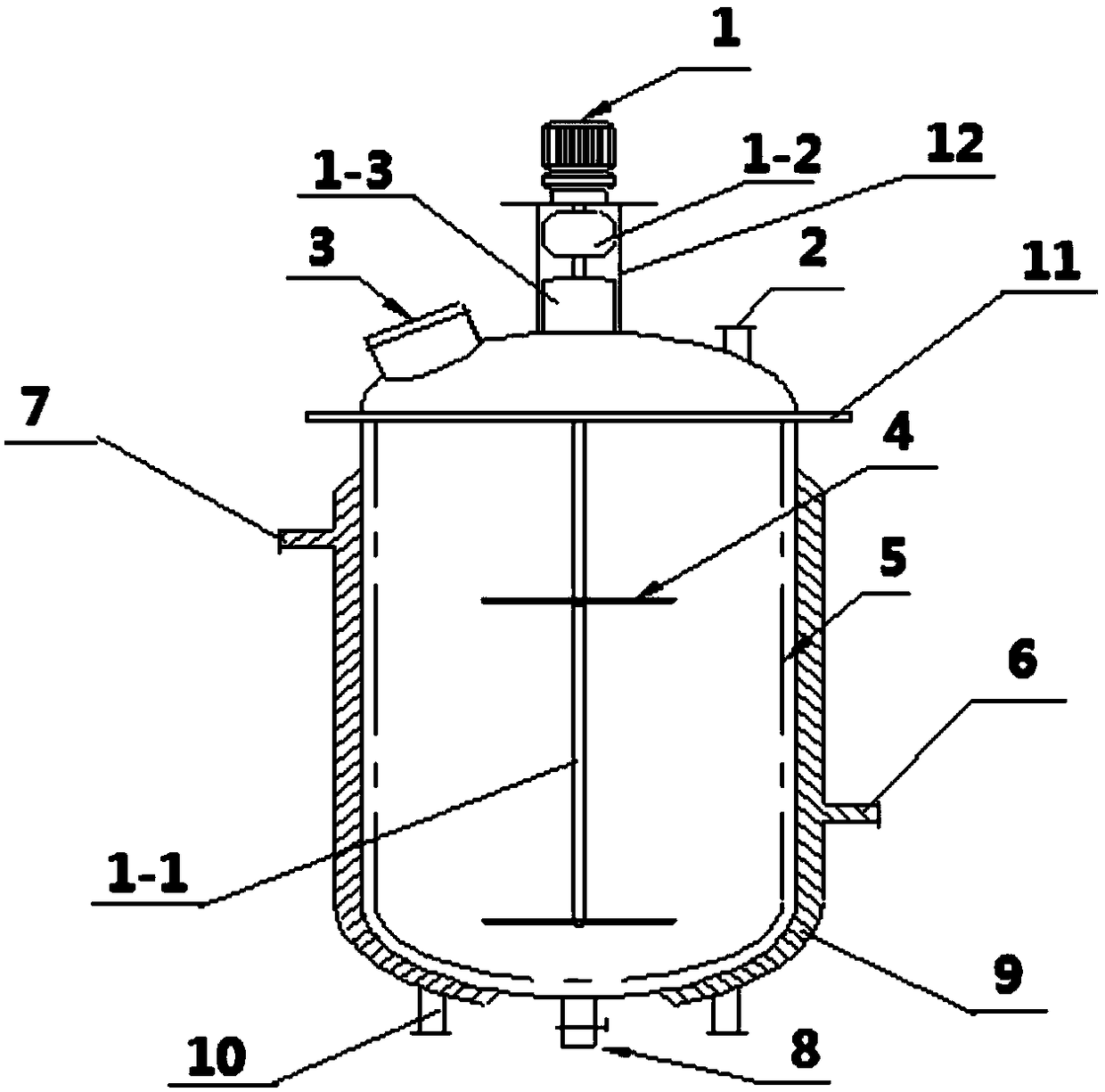

[0024] Such as figure 1 as shown,

[0025] A device for separating solid polymers from mixed emulsions, the device is a tank integrating filtration and reaction, and a transmission device 1 is arranged on the top of the tank; a double-layer part is arranged on the tank wall , and form a water passage 9; the tank wall is also provided with a filter interlayer 5; the top of the tank is provided with a feed hole 3 and a safety hole 2; near the bottom of the tank, the water passage 9 is provided with a A water inlet 6; a water outlet 7 is provided near the water channel 9 at the top of the tank; a discharge port 8 is provided at the bottom of the tank; a stirring rod 1-1 is provided on the transmission device 1, and the stirring rod 1-1 extending into the tank. The filter interlayer 5 can move up and down in the tank, or take it out of the tank, so that it can be directly separated and filtered in the reaction tank, and the liquid remains in the reaction tank; avoiding the loss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com