Garlic stalk cutting machine

A garlic and garlic stem technology, which is applied in application, food processing, food science, etc., can solve the time-consuming and labor-intensive problems of manual separation of garlic stems and garlic heads, and achieve the effects of flexible and changeable working methods, reasonable design, and efficient collection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

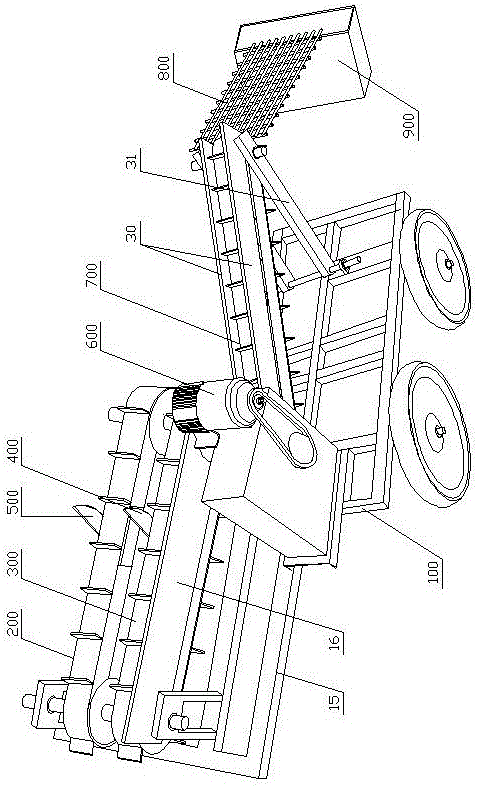

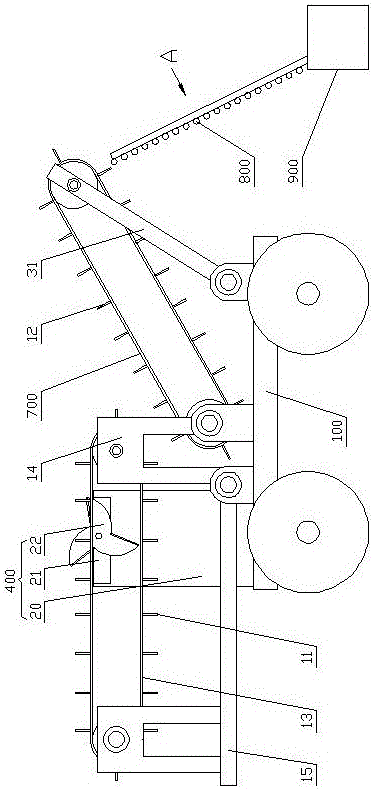

[0041] Attached below Figure 1-7 , a kind of garlic shearing machine of the present invention is described in detail below.

[0042] combined with figure 1 , 2 Shown, a kind of garlic shearing machine of the present invention, its structure comprises

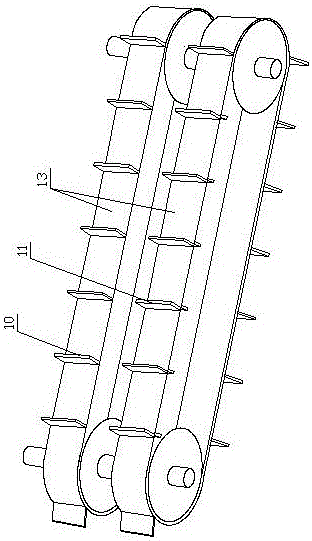

[0043]A conveyor belt device for transporting garlic, the conveyor belt device includes a conveyor belt 13 frame body, a first conveyor belt assembly 200 and a second conveyor belt assembly 300 that are arranged side by side on the conveyor belt 13 frame body, and the garlic stalks and garlic heads that have not been separated are relatively placed on the first conveyor belt assembly. The upper surface of the conveyor belt 13 of the conveyor belt assembly 200 and the second conveyor belt assembly 300, and the upper surface of the conveyor belt 13 of the first conveyor belt assembly 200 is flush with the conveyor belt 13 upper surface of the second conveyor belt assembly 300;

[0044] A first cutter assembly 400 for cutting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com