Tire manufacturing method

A manufacturing method and tire technology, which is applied in the field of tire manufacturing, can solve the problems of large gaps, tires are easy to form protrusions, tire rubber immersion, etc., and achieve the effect of improving the forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

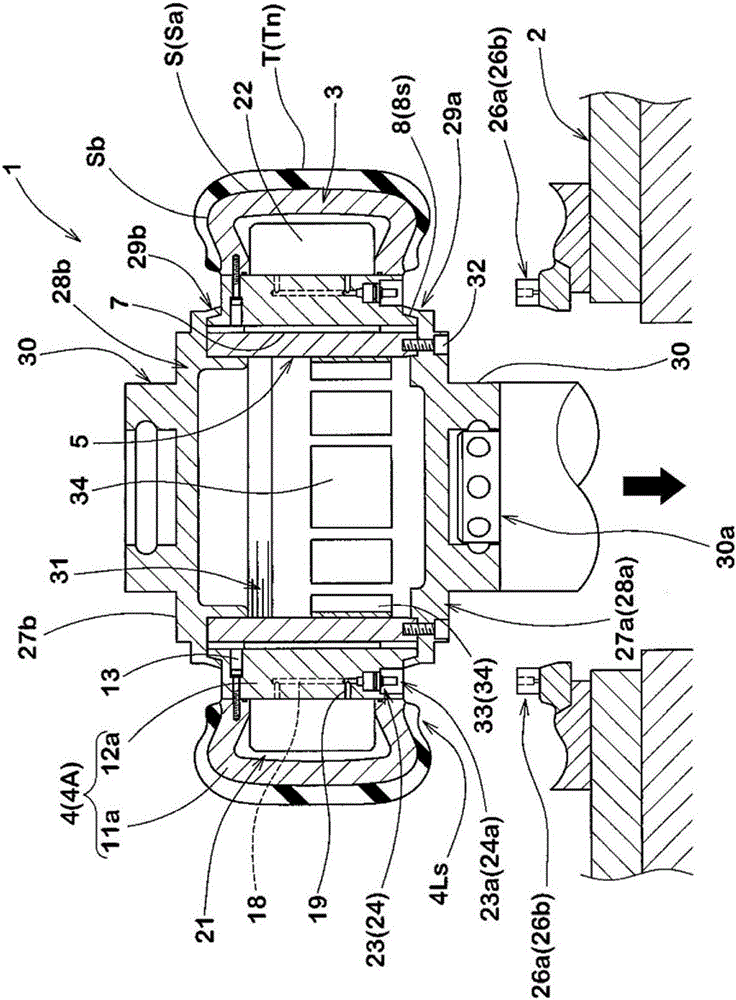

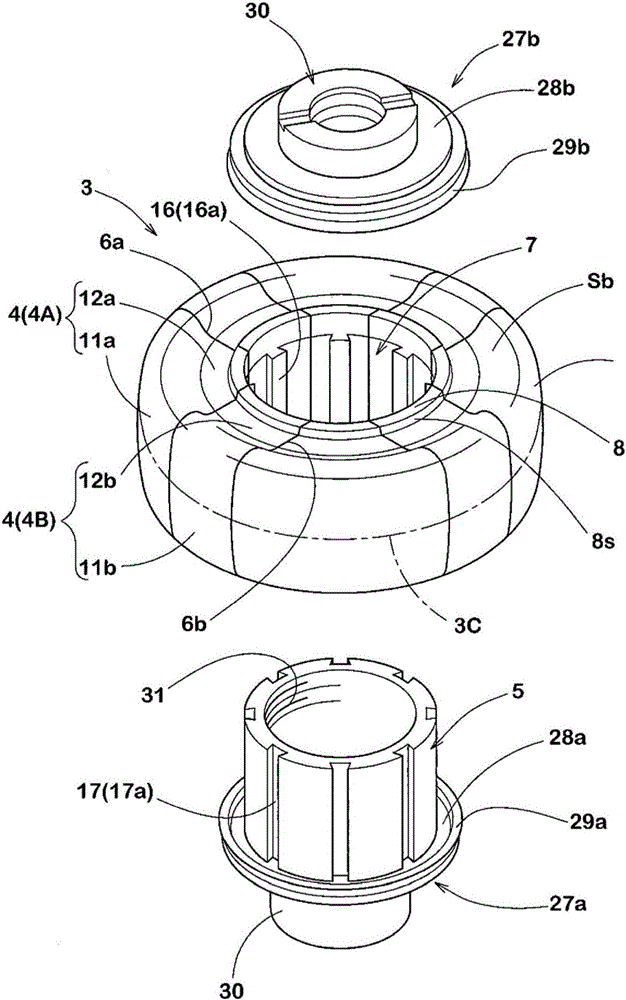

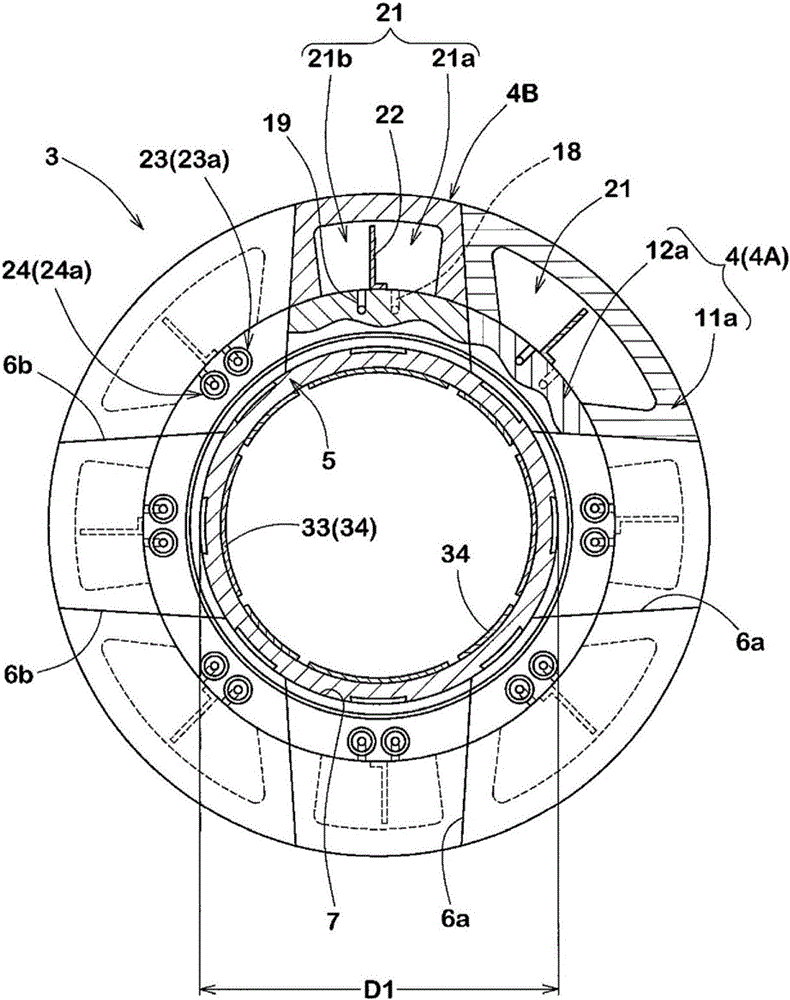

[0110] produced with figure 1 and figure 2 Rigid core shown in basic configuration and with outer diameter adjustment member (embodiment). and, according to Figure 7 For the processing steps shown, an approximate expression representing the relationship between the core temperature and the gap between the sections is obtained (eg Figure 8 shown).

[0111] Next, a vulcanization step of forming a green tire on the outer surface of the rigid core of the Example and vulcanizing the green tire was performed. In the vulcanization process, according to the approximate formula (such as Figure 8 ), the adjustment process of adjusting the outer diameter of the core is performed successively so that the gap between the segments is 0.04 mm or less. After curing, the tire and rigid core are removed from the curing mold. And, the tire is manufactured by taking out the rigid core from the inner cavity of the tire.

[0112] In addition, the presence or absence of protrusions was vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com