Lithium iron phosphate power battery formation method

A technology of power battery and formation method, applied in the field of lithium battery, can solve problems such as time-consuming, can not well adapt to the delivery cycle of power battery, etc., to improve production efficiency, improve battery electrical performance and safety performance, and avoid bulging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

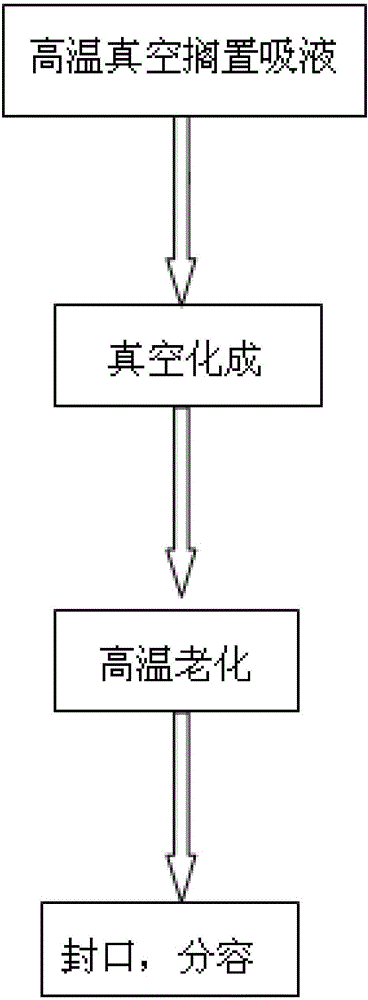

Image

Examples

Embodiment 1

[0018] In the embodiment of the present invention, a lithium iron phosphate power battery formation method, the specific steps are as follows:

[0019] (1) Put the liquid-filled battery at a high temperature of 39°C, use a vacuum formation device to keep the internal vacuum of the battery at 0.03MPa, and leave it for 24 hours to fully absorb the liquid and infiltrate the pole piece and diaphragm, and then charge;

[0020] (2) Charge the battery in stages. During the charging process, use a vacuum formation device to keep the internal vacuum of the battery between -0.03MPa to complete the formation;

[0021] (3) After the formation is completed, the battery is sealed with a clamp, and placed at a high temperature of 39°C for aging, and the aging time is 24 hours;

[0022] (4) After the aging is completed, vacuumize the battery and keep the pressure for 1 hour, and then seal the battery with a steel ball, and then carry out capacity separation.

Embodiment 2

[0024] In the embodiment of the present invention, a lithium iron phosphate power battery formation method, the specific steps are as follows:

[0025] (1) Put the liquid-filled battery at a high temperature of 43°C, use a vacuum formation device to keep the internal vacuum of the battery at 0.035MPa, and leave it for 36 hours to fully absorb the liquid and infiltrate the pole piece and diaphragm, and then charge;

[0026] (2) Charge the battery in stages. During the charging process, use a vacuum formation device to keep the internal vacuum of the battery between -0.035MPa to complete the formation;

[0027] (3) After the formation is completed, the battery is sealed with a clamp, and placed at a high temperature of 43°C for aging, and the aging time is 48 hours;

[0028] (4) After the aging is completed, vacuumize the battery and keep the pressure for 1 hour, and then seal the battery with a steel ball, and then carry out capacity separation.

Embodiment 3

[0030] In the embodiment of the present invention, a lithium iron phosphate power battery formation method, the specific steps are as follows:

[0031] (1) Put the liquid-filled battery at a high temperature of 45°C, use a vacuum forming device to keep the internal vacuum of the battery at 0.04MPa, and leave it for 48 hours to fully absorb the liquid and infiltrate the pole piece and diaphragm, and then charge;

[0032] (2) Charge the battery in stages. During the charging process, use a vacuum formation device to keep the internal vacuum of the battery between -0.04MPa to complete the formation;

[0033] (3) After the formation is completed, the battery is sealed with a clamp, and placed at a high temperature of 45°C for aging, and the aging time is 72 hours;

[0034] (4) After the aging is completed, vacuumize the battery and keep the pressure for 1 hour, and then seal the battery with a steel ball, and then carry out capacity separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com