A kind of push-pull electromagnet and preparation method thereof

A push-pull electromagnet and magnetic core technology, which is applied in the manufacture of inductors/transformers/magnets, circuits, magnets, etc., can solve problems such as the inability to meet the needs of small volume and large suction force, achieve small sliding friction coefficient, ensure action sensitivity, and guarantee The effect of stationarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

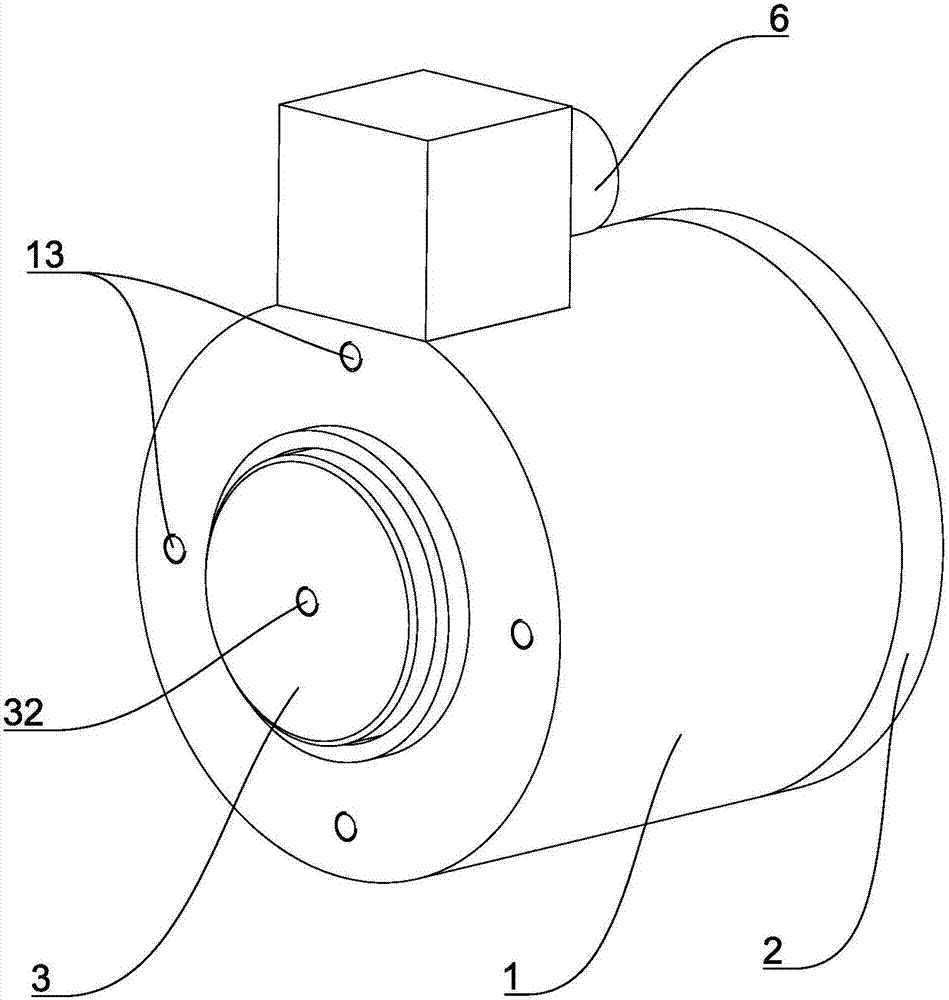

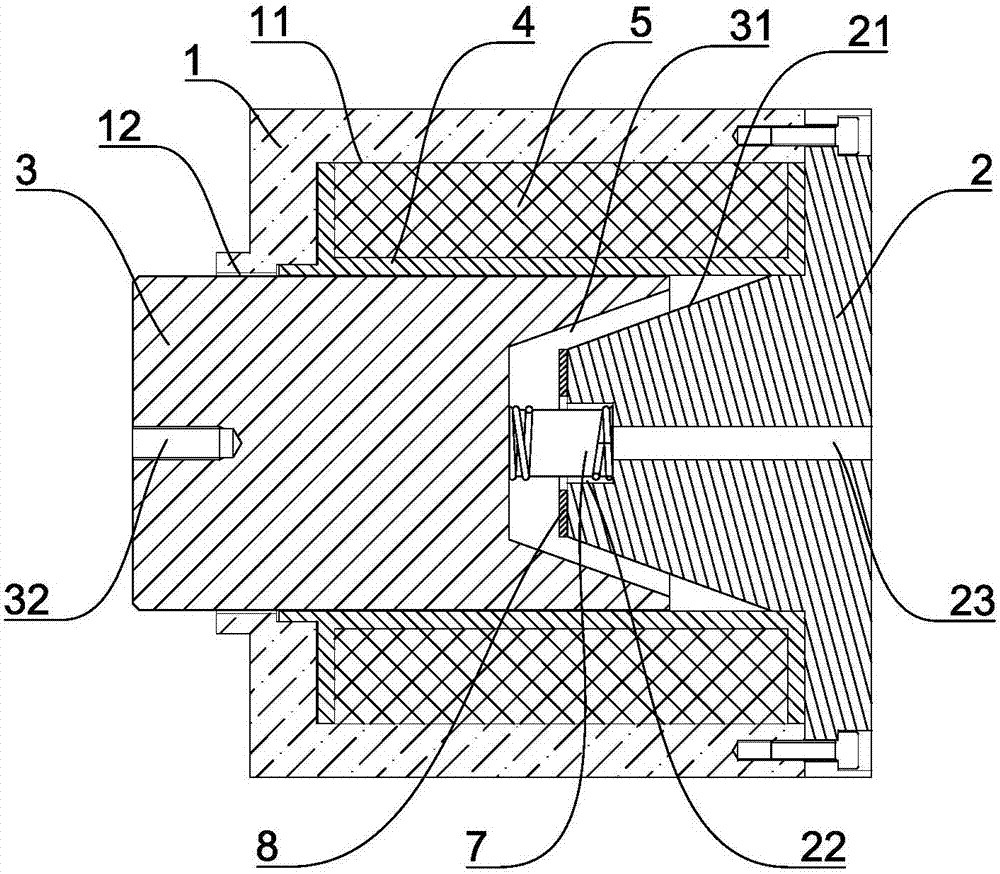

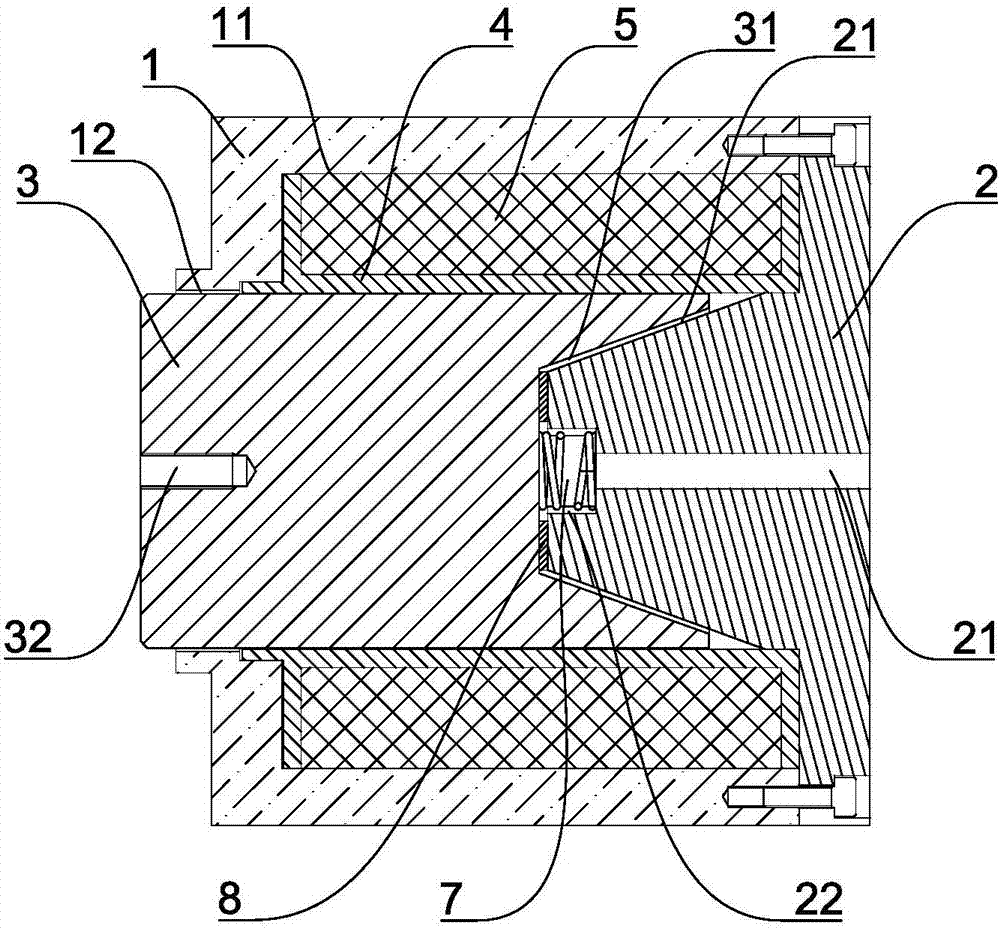

[0028] First of all, it should be explained that the present invention not only provides a push-pull electromagnet, but also provides a production and preparation method of the electromagnet. As a specific embodiment of a push-pull electromagnet of the present invention, as Figure 1 to Figure 3 As shown, it includes a housing 1 , a rear cover 2 , a moving iron core 3 , a winding bobbin 4 , a coil 5 and an electrical connector socket 6 . One end of the housing 1 is provided with a first groove 11 along the central axis for accommodating the bobbin 4 and the coil 5, and the other end of the housing 1 is provided with a first groove 11 communicating with the first groove 11 along the central axis. The through hole 12 is used for the moving iron core 3 to pass therethrough. The winding frame 4 is placed in the first groove 11 of the housing 1 and packaged by fixed connection with the housing 1 through the rear cover 2. The fixing method can be various ways such as screws and bol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com