A fault-tolerant assembly control method for flexible small parts based on cooperative petri nets

An assembly control and flexible technology, applied in the directions of adaptive control, general control system, control/regulation system, etc., can solve the problems of poor work flexibility, fault tolerance without control, etc., to meet the requirements of flexibility, fault tolerance and robustness The effect of sexual assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

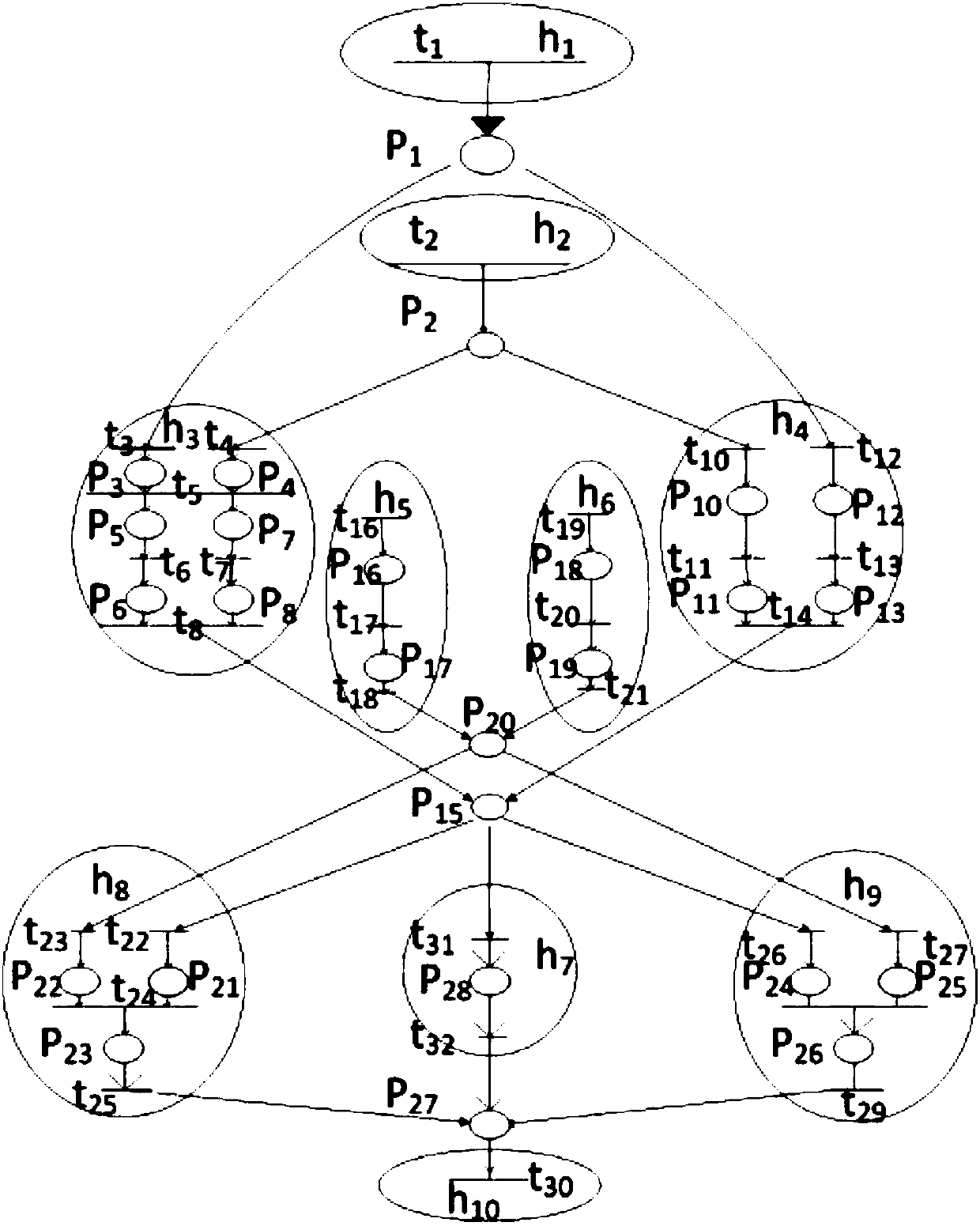

[0024] refer to figure 1 , a fault-tolerant flexible small parts assembly control method based on cooperative Petri nets, according to the process characteristics and process requirements of small electromechanical products assembly and disassembly, a Petri net model considering the collaborative process of assembly execution is established, as shown in the attached figure 1 shown.

[0025] Based on the above model, according to different production task requirements (model, specification, etc.), the logical sequence branch of the production process task rhythm and the logical branch of the raw material combination task rhythm are given, namely the so-called sub-product Petri net and raw material flow Petri net.

[0026] Based on the principle of minimum cost, combined with the queue combination optimization method, an optimized combination process of production event...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com