Liquid crystal heating device with communication function and control method

A technology of heating device and control method, applied in temperature control, control/regulation system, non-electric variable control and other directions, can solve the problem of low heating control accuracy, and achieve the effect of ensuring normal display and high heating control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

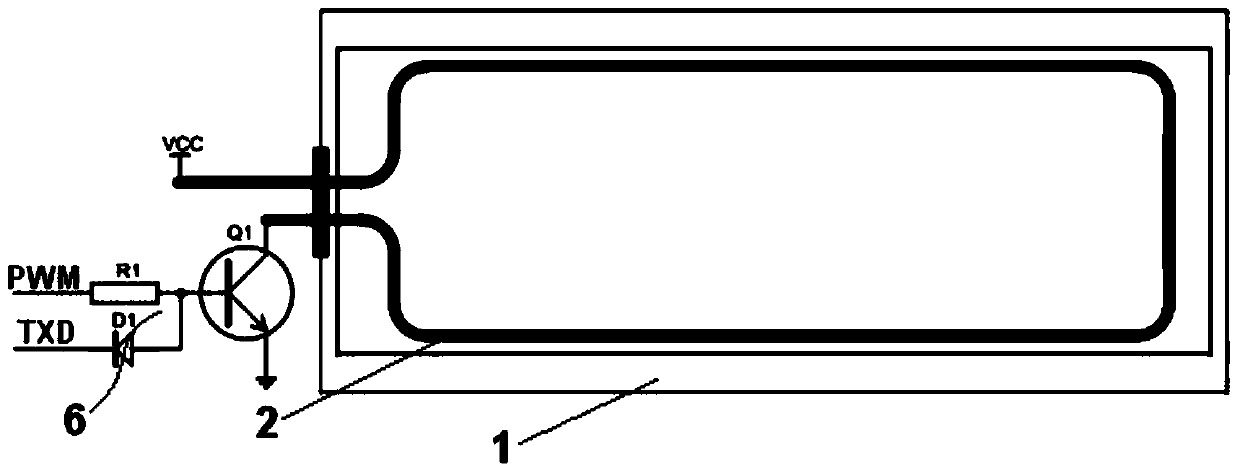

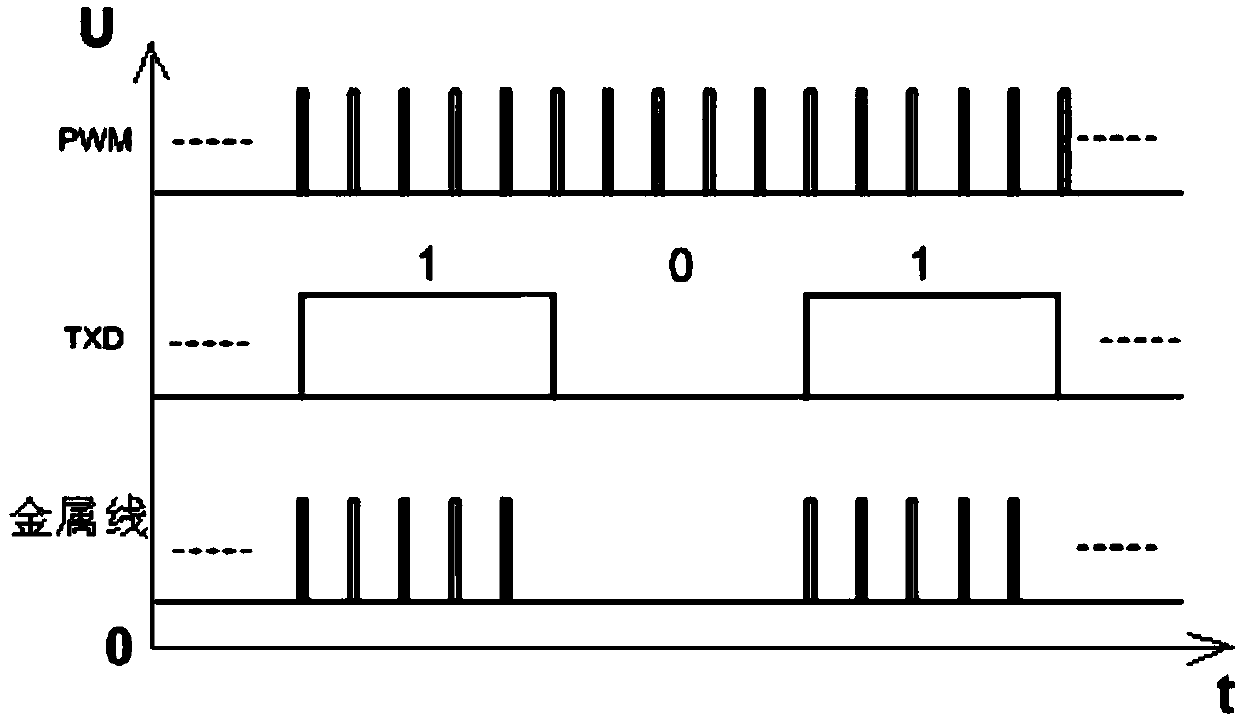

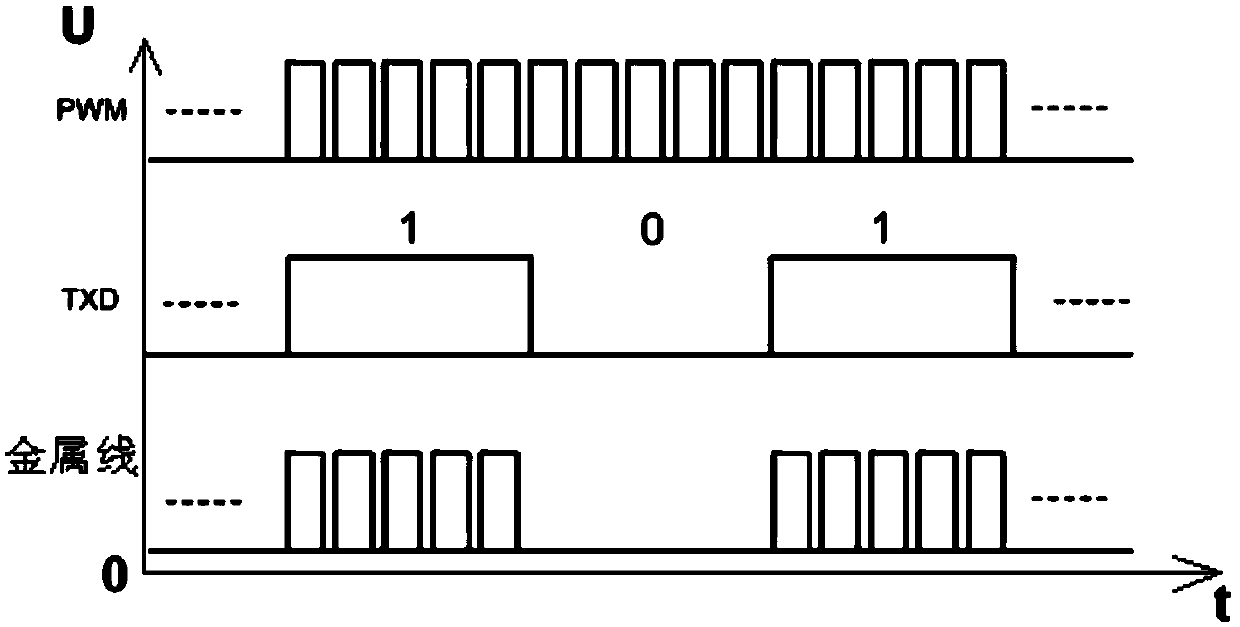

[0039] Such as figure 1 , Figure 4 The illustrated embodiment is a liquid crystal heating device with a communication function, comprising a metal wire 2 disposed on the inner surface of a liquid crystal display 1 of an electric energy meter, a single-chip microcomputer 3, a memory 4, a temperature sensor 5 and a temperature sensor disposed in the electric energy meter. Heating control circuit 6; the single-chip microcomputer is electrically connected with the memory and the temperature sensor respectively, and the metal wire is electrically connected with the VCC and the heating control circuit respectively, and the PWM switch signal output pin of the single-chip microcomputer and the metal wire heating control signal TXD pin are all connected with the heating control circuit. connect. The metal wire is made of metal electroplating layer, the metal wire extends along the edge of the liquid crystal display screen, and the metal wire is rectangular.

[0040] Such as figure ...

Embodiment 2

[0054] Embodiment 2 includes all structures and step parts of Embodiment 1, and Embodiment 2 also includes as Figure 4 The warning light 7 shown, the warning light is electrically connected with the single-chip electromechanical; Before the step 100 of embodiment 1, it also includes the temperature sensor failure detection step:

[0055] The standard temperature signal curve of the temperature sensor is set in the memory;

[0056] Step 90, the controller obtains the temperature signal curve S(t) of the temperature sensor, and the controller extracts the temperature signal value M corresponding to each time interval in S(t) 1 ,...,M n ;The serial number of the set temperature signal value is i, i=1,...,n;

[0057] Step 92, the controller utilizes the formula Calculate each temperature signal value M i The smooth rate ratio i ;

[0058] When S(t) has no intersection with the standard temperature signal curve and the ratio of each temperature signal value i If they are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com