Method for improving measurement accuracy of gas ultrasonic flowmeter

An ultrasonic flowmeter and measurement accuracy technology, applied in liquid/fluid solid measurement, measurement flow/mass flow, measurement devices, etc., can solve problems such as large measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will take the DN100 radial type monophonic gas ultrasonic flowmeter as an example ( figure 1 ), combined with the step method in the technical solution, the parameter setting and implementation method of each step are given:

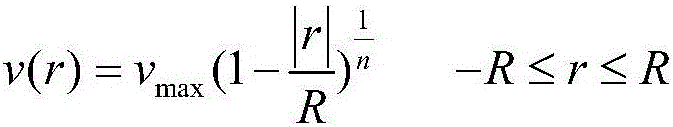

[0015] Step 1: Ideally, the upstream of the ultrasonic flowmeter will be equipped with a long straight pipe section upstream, so it can be considered that the velocity distribution flowing into the ultrasonic flowmeter satisfies the fully developed turbulent velocity distribution, as shown in the following formula.

[0016] v ( r ) = v m a x ( 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com