U-shaped heat pipe array device and air conditioning system with the same

A technology of heat pipes and arrays, which is applied in the field of heat exchange, can solve the problems of adverse effects of heat pipes and thermosiphons on heat exchange performance, inconvenience of large-scale manufacturing and filling, and inability to make complex loops, etc., to achieve uneven distribution of cold and heat sources. , industrial design and manufacture are convenient, and the accuracy of filling rate is easy to guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

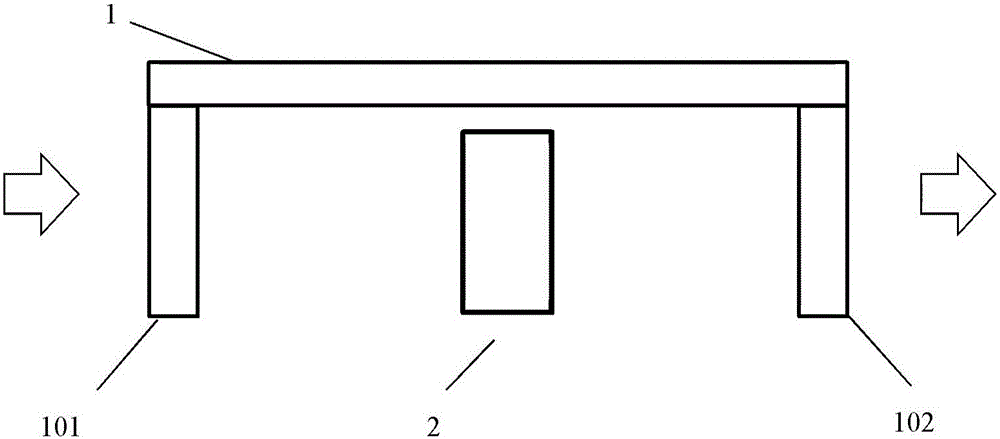

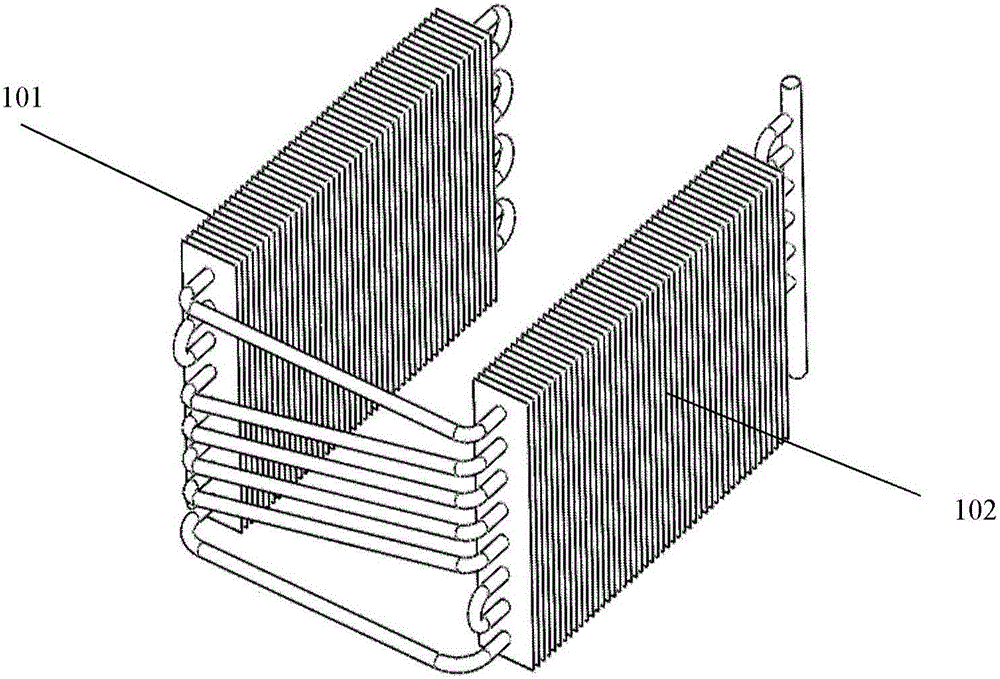

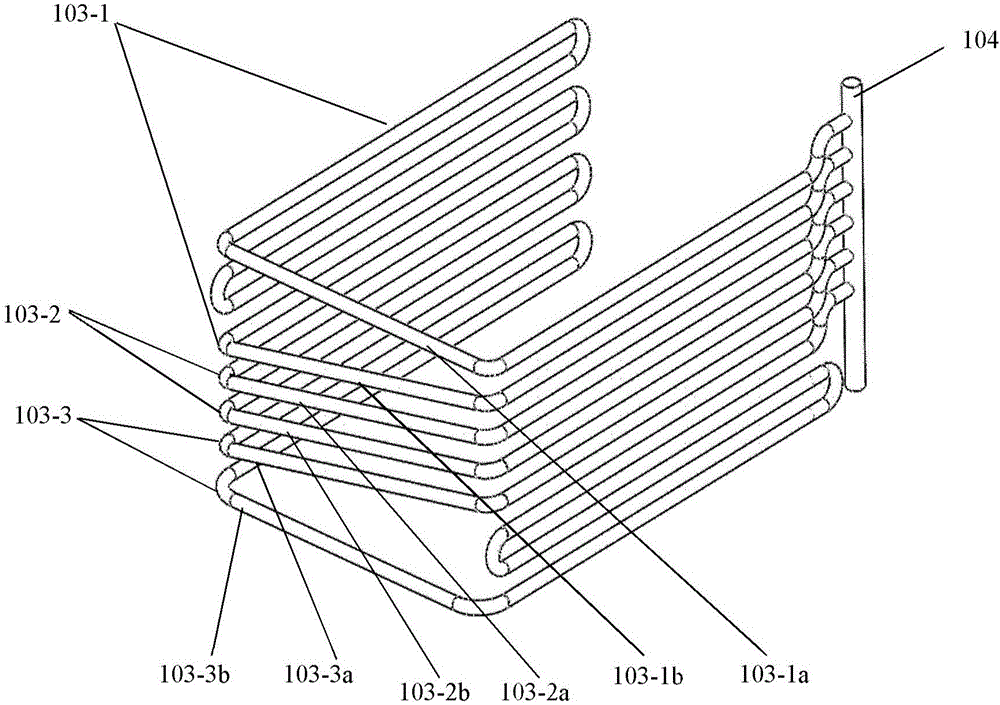

[0042] According to the general inventive concept of the present invention, a U-shaped heat pipe array device is provided, comprising two straight arm parts and a curved part connecting the two straight arm parts, wherein:

[0043] One of the two straight arm parts is a condensation end, and the other is an evaporation end, both of which include multiple horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com