A new four-node j-drum integrated laying system

A four-node, reel technology, applied in the direction of pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of laying capacity, limited length of installable pipes, easy to generate circumferential strain, increase operation risks, etc. problems, achieve the effect of strengthening comprehensive operation ability, improving laying quality and efficiency, and ensuring laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

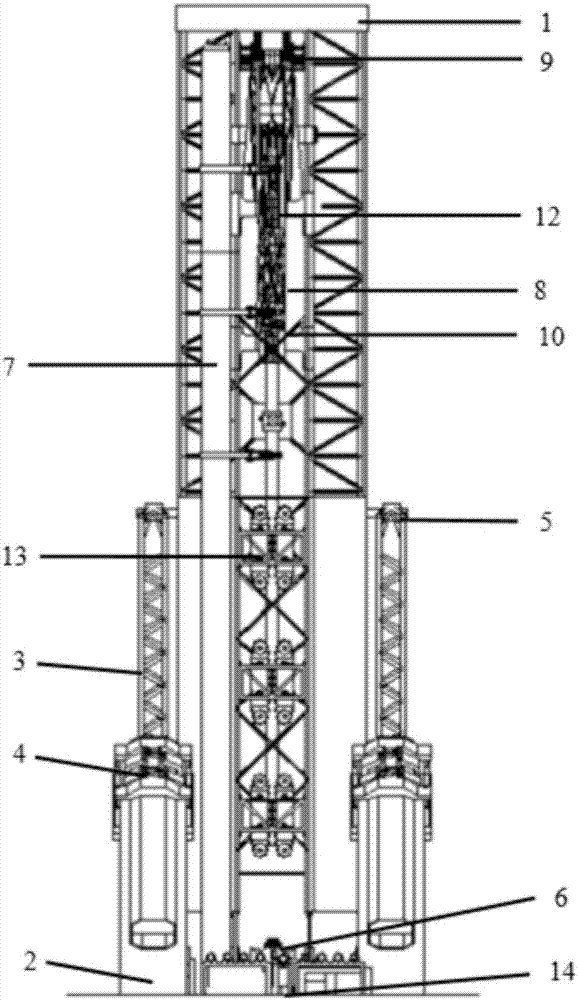

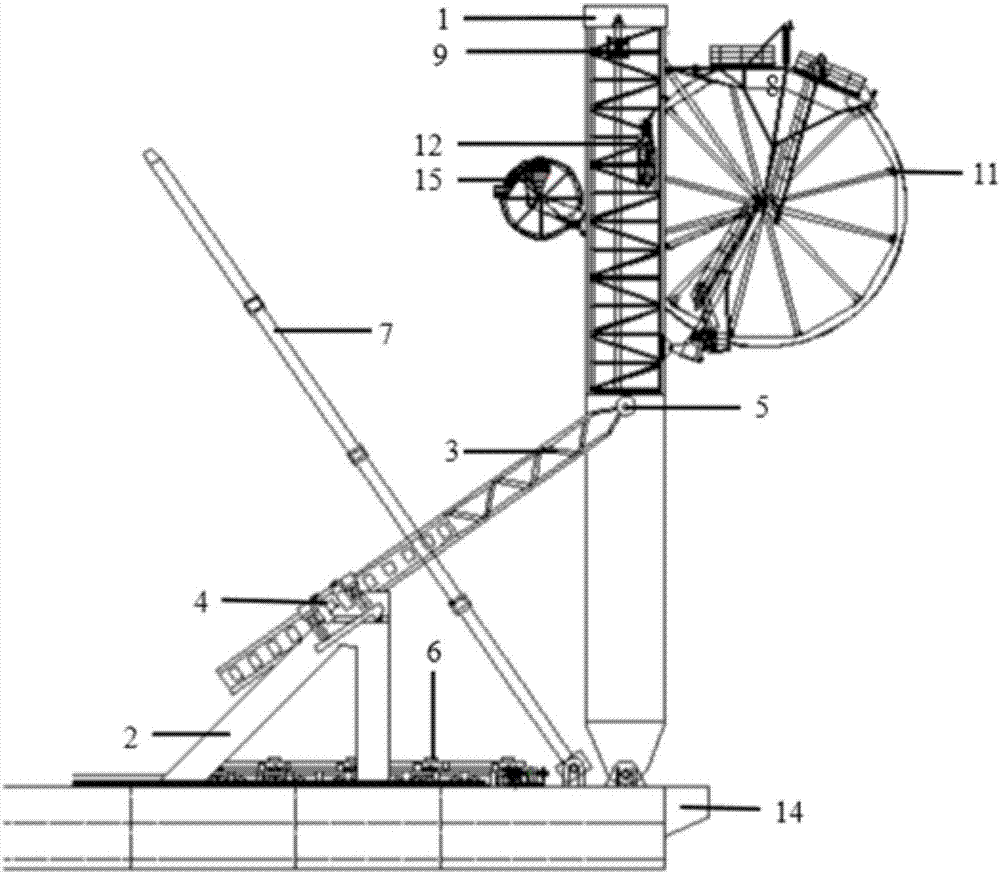

[0030] combine Figure 1 to Figure 11 , a new four-node J-type reel integrated laying system of the present invention mainly includes a laying tower 1, a reel 11, a laying tower angle adjustment system, a straightening system 12, a pipe laying transmission system and key equipment for pipe laying. The laying tower angle adjustment system includes A frame 2, angle adjuster 3, hydraulic cylinder 4, angle adjuster connecting shaft 5; straightening system 12 includes calibration wheel 15, straightening device 8 and straightening roller 10; pipeline laying pipeline transmission The system includes a horizontal transmission system 6 , a loading arm 7 , and a hoist 9 ; key equipment for laying pipelines includes a tensioner 13 and a mobile platform 14 .

[0031] The laying tower 1 is 52 meters high, which can meet the laying operation of 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com