Multi-section telescopic rod with self pushing and pulling functions

A combination of telescopic rod and technology, which is applied in the field of push-pull and mechanical telescopic, to solve the effect of inconvenient use, simple structure and large lifting distance of the escalator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

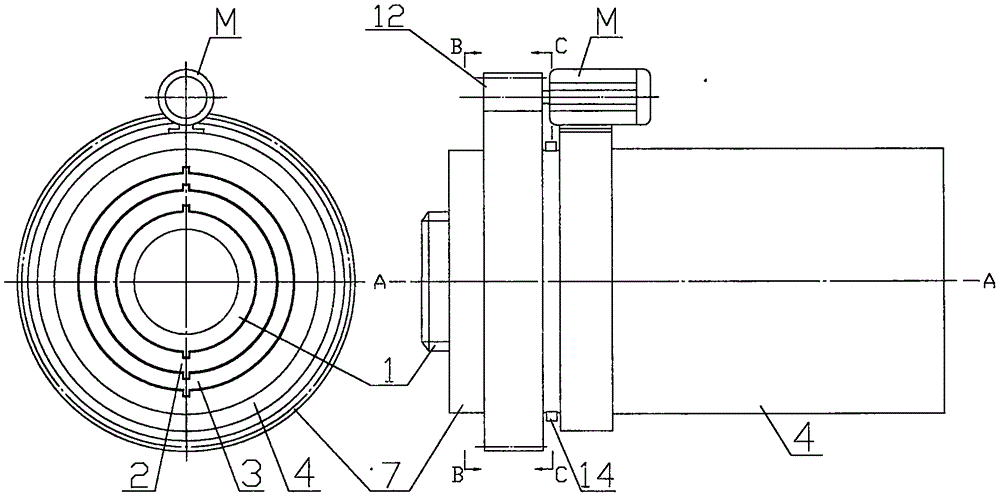

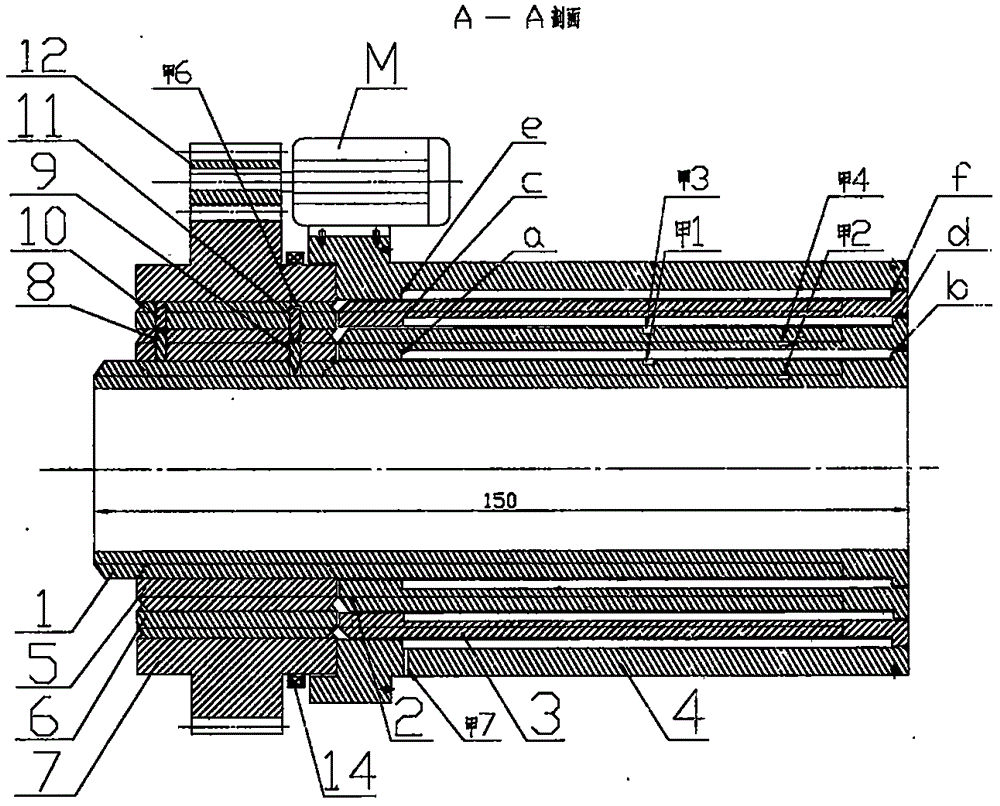

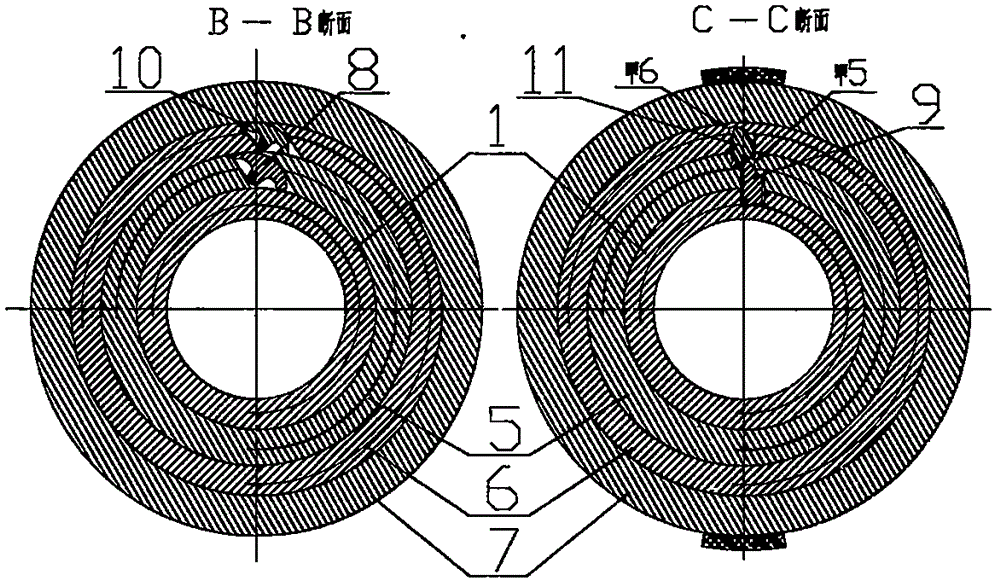

[0039] Such as figure 1 , figure 2 , the implementation of the full extension of the four-section telescopic rod is as follows:

[0040] At this moment, each joint telescopic link is all in the retracted state, and the shell 13 (in Figure 4 Have in picture) gear 12, internally threaded gear 7 and hollow pipe 4 are fixed, internally and externally threaded nut 5,6 coincides with internally threaded gear 7, is bolted by lock pin 9,11 simultaneously (as image 3 ). (Viewed from right to left) When the motor drives the gear 12 to rotate clockwise, the internally threaded gear 7 and the internally and externally threaded nuts 5 and 6 rotate counterclockwise together, the screw 1 protrudes outward, and when the protruding chuck b at the root of the screw 1 is displaced When reaching the end point a of the inner wall groove of the externally threaded hollow rod 2, the externally drawn screw 2 fits the internally and externally threaded nut 5, and the screw thread crest groove A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com