A kind of pulp pump with large amount of injection and small amount of injection

A micro, excellent technology, applied in the direction of pump components, variable displacement pump components, components of pumping devices for elastic fluids, etc., can solve the problems of color paste pressure deformation, pump rod stroke change, affecting accuracy, etc., to achieve Small footprint, good leak-proof performance, and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The following will be described in conjunction with the accompanying drawings and embodiments.

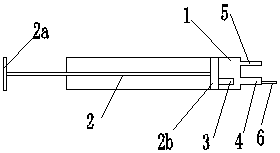

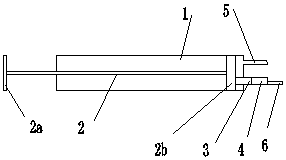

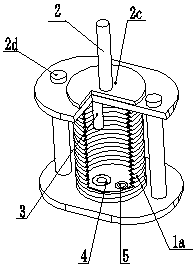

[0079] A color paste pump that not only injects a large amount of color paste but also injects a small amount of color paste disclosed by the present invention is shown in Figure 1a and Figure 1b. Including the large reciprocating rod 2, the energy-applying end 2a of the large reciprocating rod 2, the piston 2b driven by the large reciprocating rod 2), the small pump body space II with volume change, that is, the small cylinder 4, the small reciprocating member, that is, the small reciprocating rod 3, and the large pump The inlet and outlet 5 and the inlet and outlet of the small pump 6; the large cylinder body 1, the large reciprocating piece and the big pump inlet and outlet 5 constitute a large reciprocating volumetric pump; the small reciprocating piece, the small pump body and the small pump inlet and outlet 6 constitute a small reciprocating volumetric pump ; The small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com