Single-well desanding device and sand discharging technology thereof

A process and sand filtration technology, applied in wellbore/well components, production fluids, earthwork drilling, etc., can solve the problems of mixing in liquid, economic loss, high pressure, simplify oil and gas technical process, reduce construction investment, shorten The effect of the construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

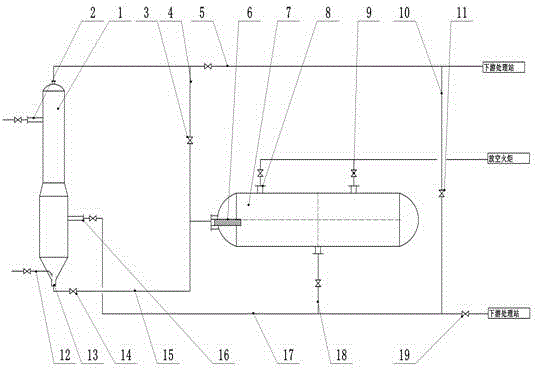

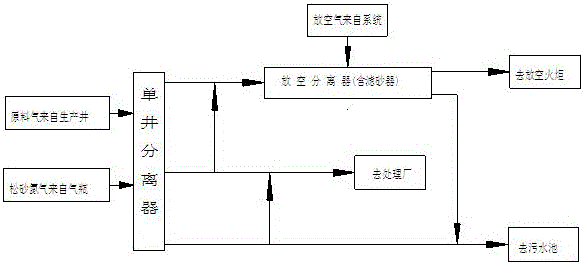

[0025] Such as figure 1 As shown, a single well desanding device includes a vertical gas-liquid-sand three-phase separator and a vent separator; the three-phase separator is connected with multiple inlets and multiple outlets, and the inlet of the three-phase separator includes The upper part of the three-phase separator is provided with the raw material incoming gas inlet and the lower part is provided with the loose sand gas inlet. The outlet of the three-phase separator includes a gas outlet, a liquid outlet and a sand outlet.

[0026] The sand discharge outlet is connected to the vent separator inlet through a sand discharge passage, a sand discharge valve that can cut off the sand discharge passage is provided on the sand discharge passage, and a gas transmission branch valve that can cut off the gas transmission branch is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com