Combined type large-capacity typhoon-resistant silo and manufacturing method thereof

A large-capacity, combined technology, applied in large-capacity bulk material storage, building types, buildings, etc., to achieve the effect of easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

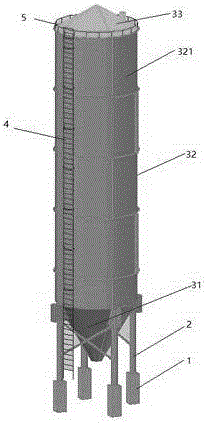

[0030] The invention discloses a combined large-capacity platform-proof silo. Such as figure 1 As shown: it includes a concrete foundation 1, a base 2, and a silo body 3; the base 2 is set on the concrete foundation 1, and the base 2 is a frame composed of a single rod; the silo body 3 is fixed on the base 2 , and the silo body 3 includes a silo bottom 31, a cylinder 32 and a silo roof 33, the cylinder 32 is spliced by arc-shaped steel plates 321; the silo body 3 is also equipped with auxiliary facilities. The auxiliary setting is ladder 4 and lightning rod 5.

[0031] A manufacturing method of the above-mentioned combined large-capacity typhoon-proof silo, which includes the following steps:

[0032] Step 1: Splicing several arc-shaped steel plates 321 and connecting them with bolts to form a cylinder 32, such as image 3 , 4 .

[0033] Step 2: Stake out the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com