a roof device

A floor and web technology, applied to floors, buildings, building components, etc., can solve the problems of short service life of fireproof boards, lack of large-scale promotion and use, and increase the load bearing of buildings, so as to achieve high impact resistance and facilitate standardization The effect of high construction and support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described with reference to the accompanying drawings.

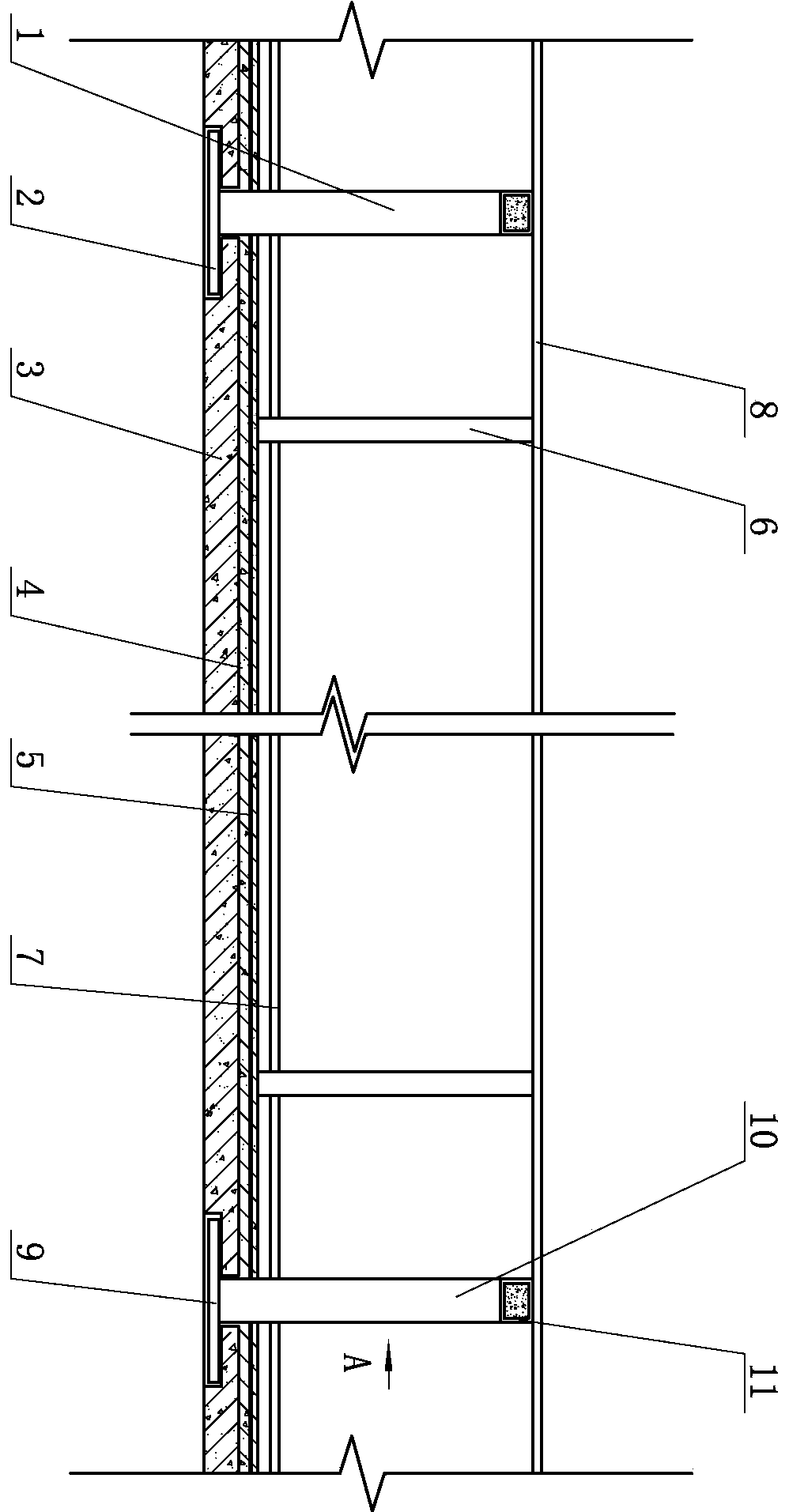

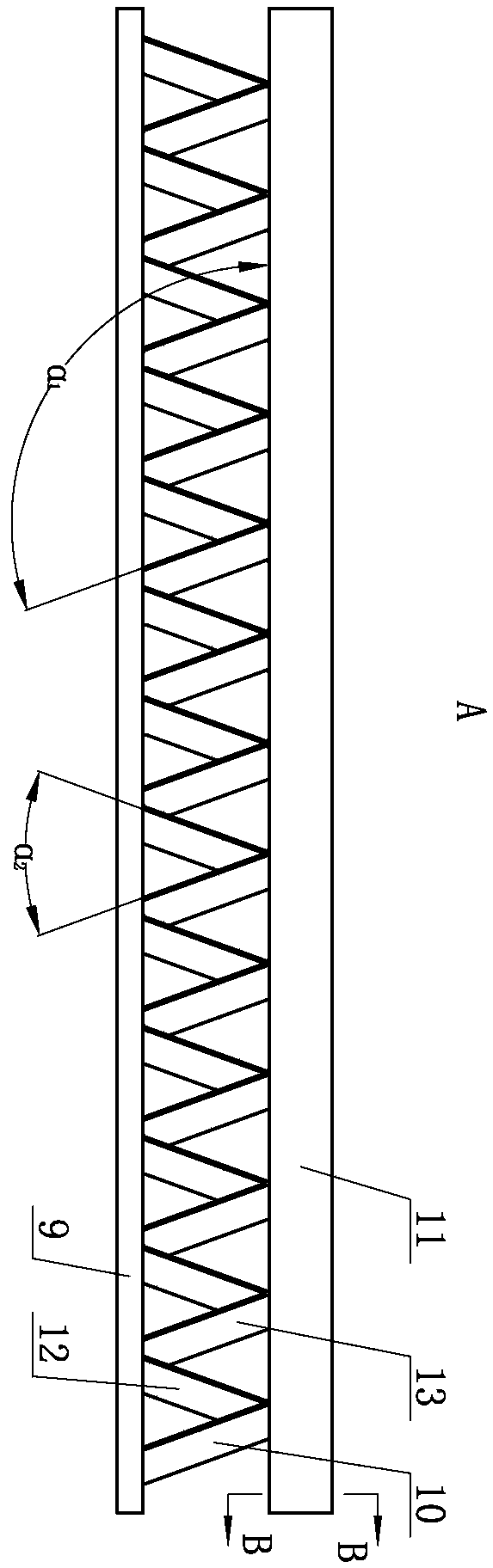

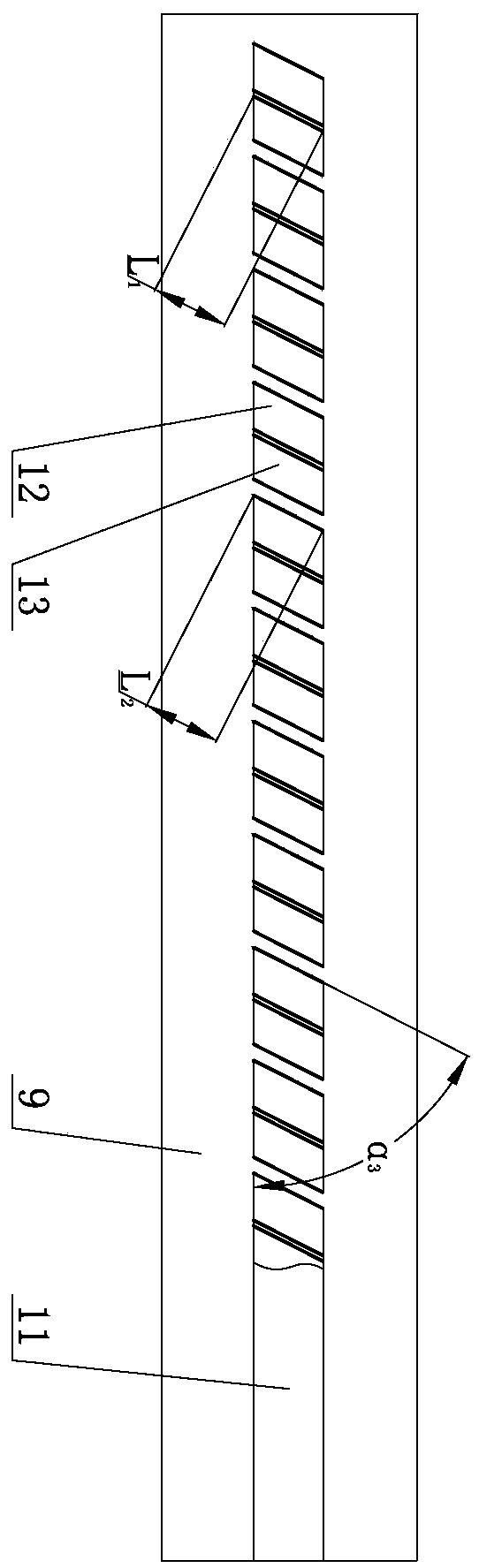

[0008] 3 in the figure is a prefabricated floor, the upper part of the prefabricated floor 3 is provided with a floor 8, and a cavity 14 is provided between the prefabricated floor 3 and the floor 8, and several first webs 10 and several second webs 12 are installed in the cavity 14. The upper ends of the first web 10 and the second web 12 are connected to the wing bar 11, and the wing bar 11 is connected to the floor 8, and the lower ends of the first web 10 and the second web 12 are connected to the support plate 9, and the support plate 9 Connected with the prefabricated bottom plate 3, the first angle α is set between the first web 10 and the wing bar 11 1 , the first included angle α 1 Greater than 90°, a second angle α is set between the first web 10 and the second web 12 2 , the second included angle α 2 It is an acute angle, several first webs 10 are parallel and ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com