Method for increasing shipping efficiency of ship lock as well as roll-on roll-off vessel

A technology of ship lock and efficiency, applied in the field of rolling ships, can solve the problems of time-consuming sound and time-consuming, and achieve huge economic benefits, reduce positioning time, and save positioning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

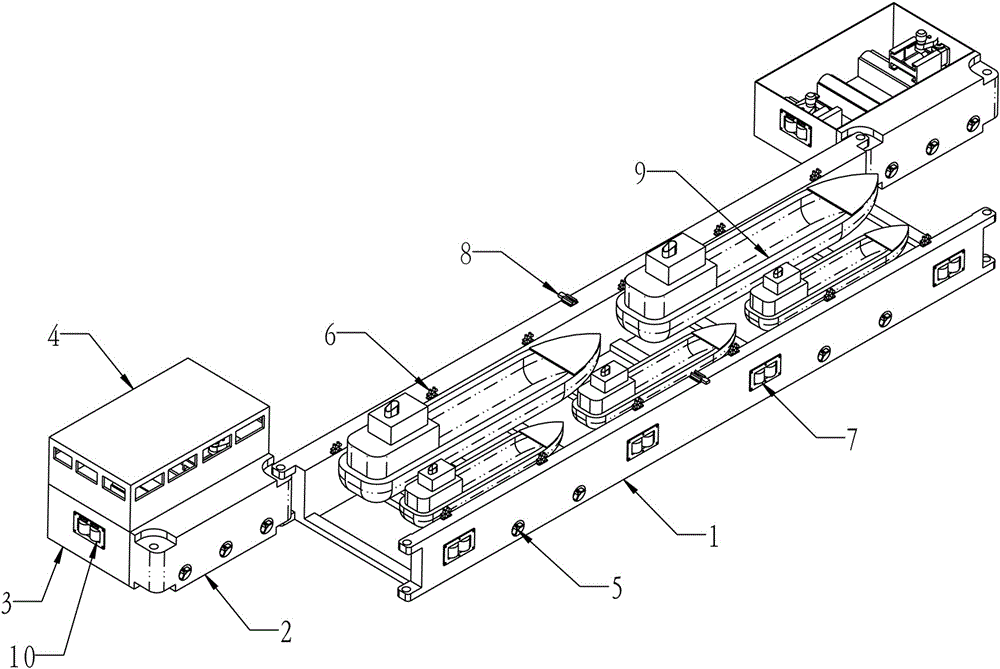

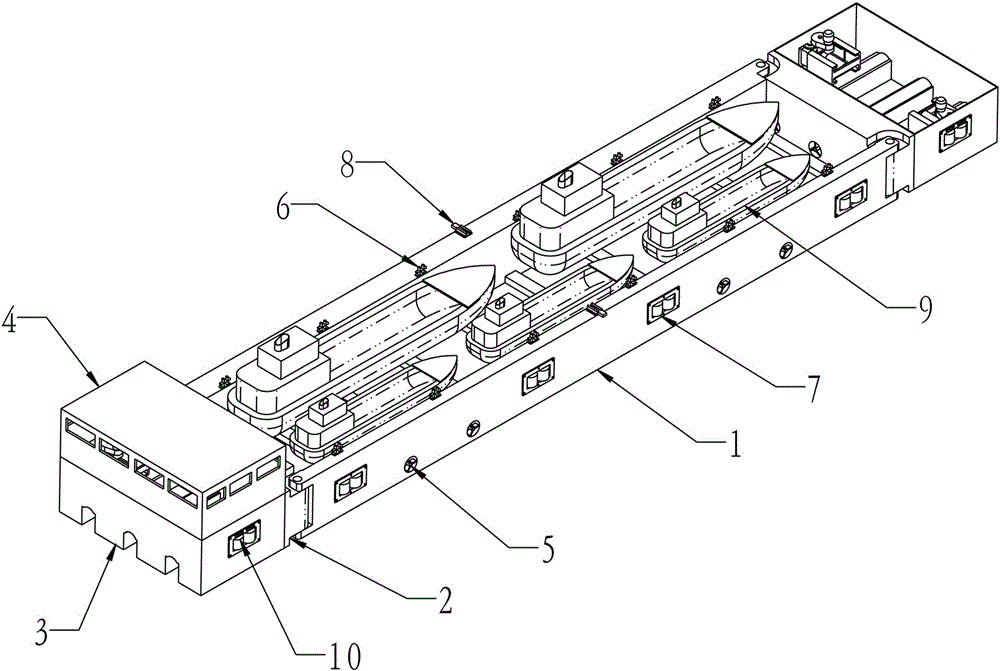

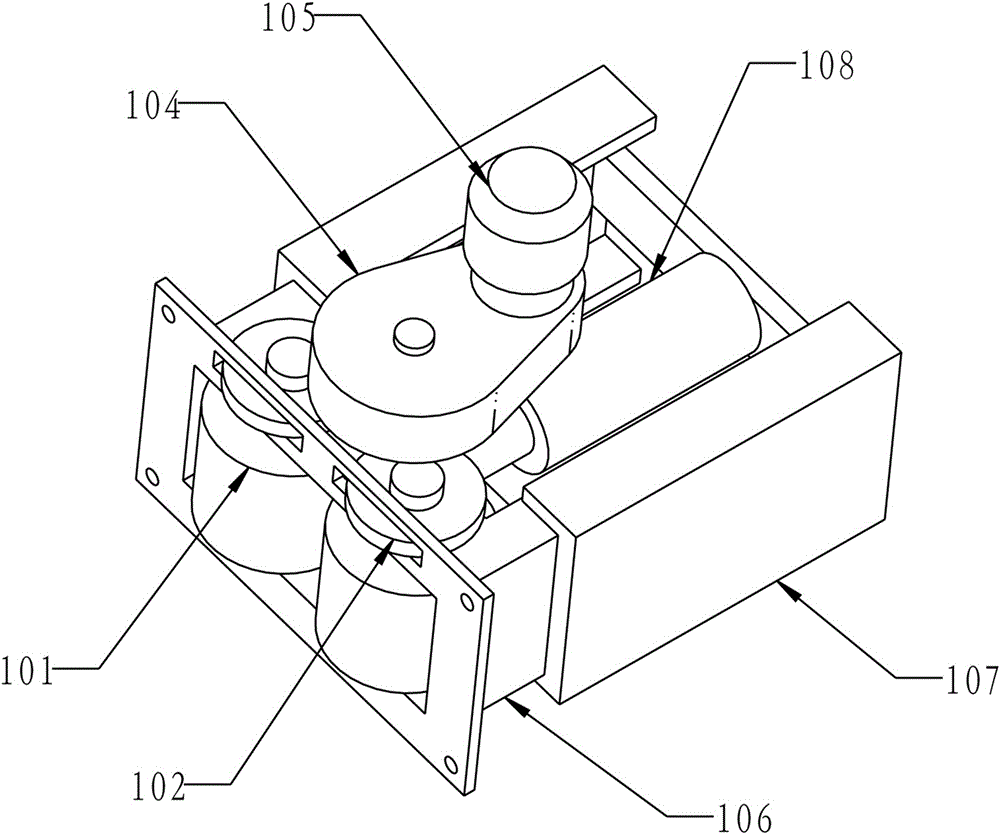

[0015] Specific implementation method: in figure 1 Among them, the rolling ship body has a channel frame 1, the two ends of the channel frame 1 are open, and the ship can go straight in and out in the channel frame 1, and the channel frame 1 is equipped with bollards 6. The end of the channel frame 1 is either connected with a floating door 2 or connected with a power ship box 3 . A propeller 5 is installed under the channel frame 1 or the floating door 2 or the power ship box 3, and a roller 7 is installed on the side of the channel frame 1 against the lock chamber. Locating pins 8 are installed on the grooved frame 1 . Locating pin 8 is exactly a big bolt, for avoiding rolling ship collision gate, when rolling ship reaches the position that lock chamber is set, let locating pin 8 stretch out groove frame 1 limit, insert in the vertical groove of ship lock chamber wall, rolling ship is in Just be positioned front and back, left and right in the lock chamber, diesel engine a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com