Liquor brewage cooling system

A technology of cooling cylinder and cooling pipe, applied in the field of wine cooling system, can solve the problems of insufficient cooling, low cooling efficiency, traditional structure, etc., and achieve the effects of simple structure, improved efficiency and increased cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

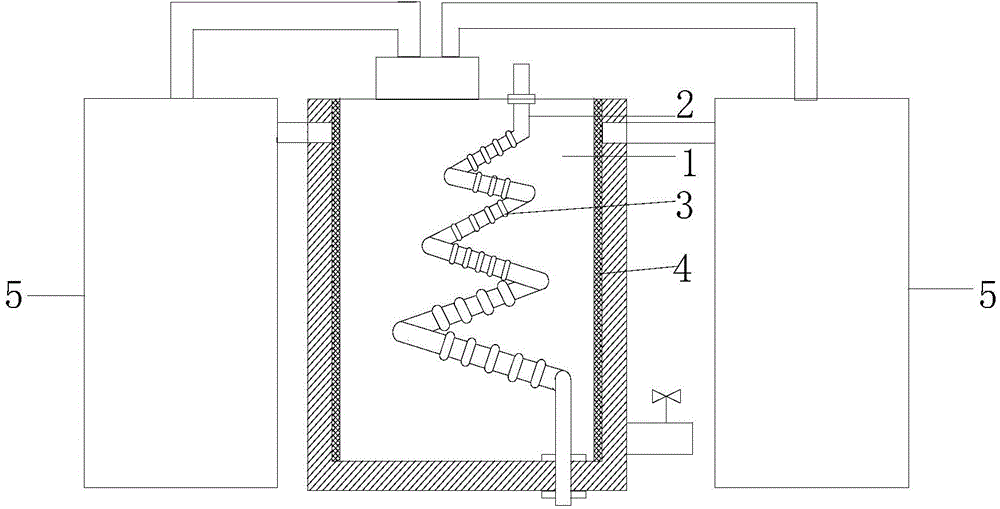

[0013] figure 1 It is a schematic structural diagram of the present invention, as shown in the figure: the brewing cooling system of the present invention includes a cooling cylinder 1 provided with a wine vapor inlet and a circulating cylinder 5 connected to both sides of the cooling cylinder 1 through a circulating pump. The cooling cylinder 1 is provided with a spiral cooling pipe 2 containing a cooling medium. The cooling pipe 2 is sealed in the cooling cylinder 1 in a horizontally rotatable manner along the cooling cylinder 1 and passes through the bottom of the cooling cylinder 1; The cooling pipe 2 can be rotated horizontally. The cooling medium in the cooling pipe 2 adopts circulating cooling liquid. The cooling pipe 2 rotates slowly to increase the residence time of the cooling liquid in the cooling pipe 2 for sufficient heat exchange. , And it can disturb the liquid in the cooling cylinder 1, and at the same time, it uses a multi-circulation method for multiple coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com