A kind of preparation method of joint sealing material

A technology of sealing materials and raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

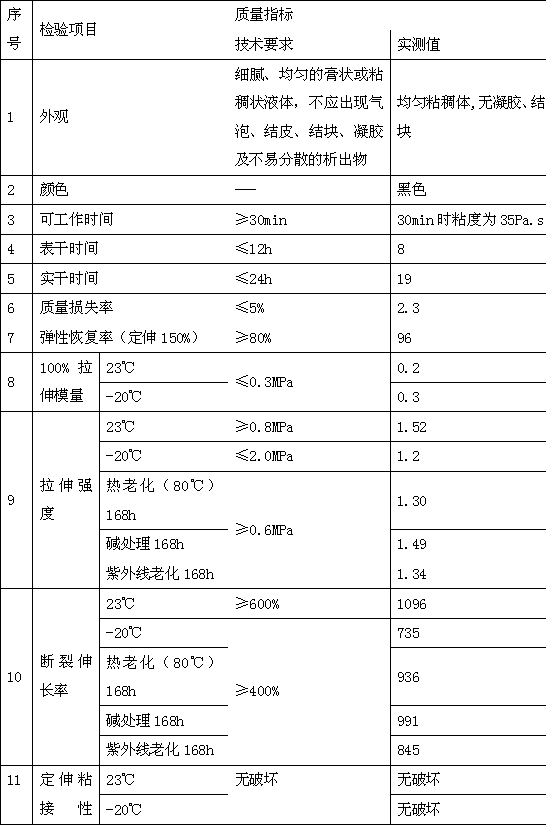

[0031] The technical solution of the present invention is a preparation method of a joint filling and sealing material, including the following steps:

[0032] A preparation

[0033] 1) Part A: (parts by weight)

[0034] Polyether polyol DL-2000D 60-80

[0035] Polyether polyol EP-330N 10-30

[0036] Diphenylmethane diisocyanate MDI-50 10-20

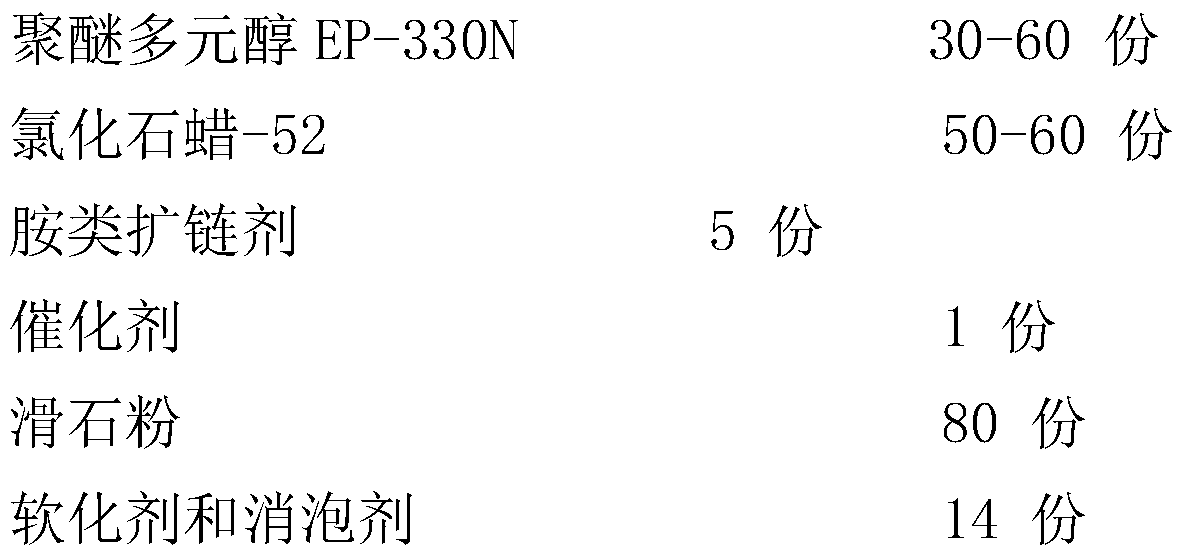

[0037] 2) Part B: (parts by weight)

[0038] Polyether polyol EP-330N 30-60

[0039] Chlorinated Paraffin-52 50-60

[0040] Amine chain extender (MOCA) 5

[0041] Organometallic catalyst 1

[0042] Talc 80

[0043] Softeners and defoamers 14

[0044] B. Preparation

[0045] Add the polyether polyol in the first component into the container, stir, heat up to 60-80°C, add MDI-50, heat up to 80°C, react at 80±2°C for 2h, and determine when the NCO content of the system reaches the predetermined value , Stop the reaction. After the reaction is completed, the temperature is lowered and vacuum degassing for 30 minutes, and the material is discharged to obtain ...

Embodiment 1

[0070] Follow the steps A, B, D, and E described in the above specific embodiment. among them:

[0071] A preparation

[0072] 1) Part A: (parts by weight)

[0073] Polyether polyol DL-2000D 60

[0074] Polyether polyol EP-330N 10

[0075] Diphenylmethane diisocyanate MDI-50 10

[0076] 2) Part B: (parts by weight)

[0077] Polyether polyol EP-330N 30

[0078] Chlorinated Paraffin-52 50

[0079] B. Preparation

[0080] Add the polyether polyol in component A into the container, stir, and heat to 60°C;

[0081] After the component B is stirred and dispersed evenly, it is heated to 100°C.

Embodiment 2

[0083] Repeat Example 1 but,

[0084] A preparation

[0085] 1) Part A: (parts by weight)

[0086] Polyether polyol DL-2000D 80

[0087] Polyether polyol EP-330N 30

[0088] Diphenylmethane diisocyanate MDI-50 20

[0089] 2) Part B: (parts by weight)

[0090] Polyether polyol EP-330N 60

[0091] Chlorinated Paraffin-52 60

[0092] B. Preparation

[0093] Add the polyether polyol in the first component into the container, stir, heat up to 80°C, add MDI-50, heat up to 80°C, after the reaction is completed, cool down and degas in vacuum for 20 minutes;

[0094] After the component B is stirred and dispersed evenly, it is heated to 110°C and dehydrated under vacuum for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com