Formula and production method of waterproof breathable water-in-water multicolour coating

A technology of multi-color coatings and production methods, applied in the field of coatings, can solve problems such as color spot bleeding, poor water resistance, and easy sagging of multi-color coatings, and achieve the effects of reducing dosage and changing hydrophobicity and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

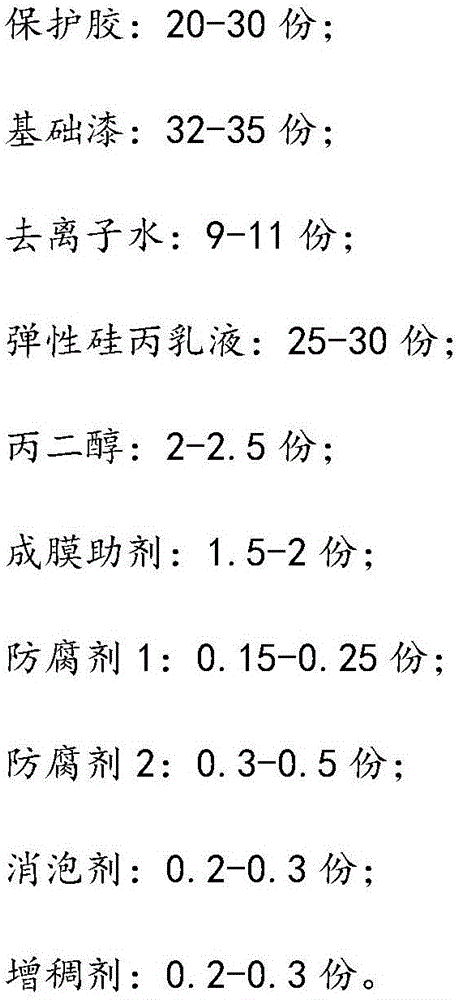

[0026] Water-resistant and breathable water-in-water multi-color paint formula, composed of the following components by mass: protective glue: 20-30 parts; base paint: 32-35 parts; deionized water: 9-11 parts; elastic silicone acrylic emulsion: 25 parts -30 parts; propylene glycol: 2-2.5 parts; coalescent: 1.5-2 parts; preservative 1: 0.15-0.25 parts; preservative 2: 0.3-0.5 parts; defoamer: 0.2-0.3 parts; thickening Dosage: 0.2-0.3 parts.

[0027] Preferably, the water-resistant and breathable water-in-water multicolor paint formula is composed of the following components by mass: protective glue: 20 parts; base paint: 33.2 parts; deionized water: 11 parts; elastic silicone acrylic emulsion: 30 parts; propylene glycol : 2.5 parts; film-forming aid: 2 parts; preservative 1: 0.2 parts; preservative 2: 0.5 parts; defoamer: 0.3 parts; thickener: 0.3 parts.

[0028] Preferably, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com