Extraction technology of hijiki polysaccharide

A hijiki polysaccharide and extraction process technology, applied in the field of bioengineering, can solve the problems of low polysaccharide yield, long production time, and easily damaged polysaccharides, and achieve the effect of rich nutrition, simple equipment, and clear operating units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

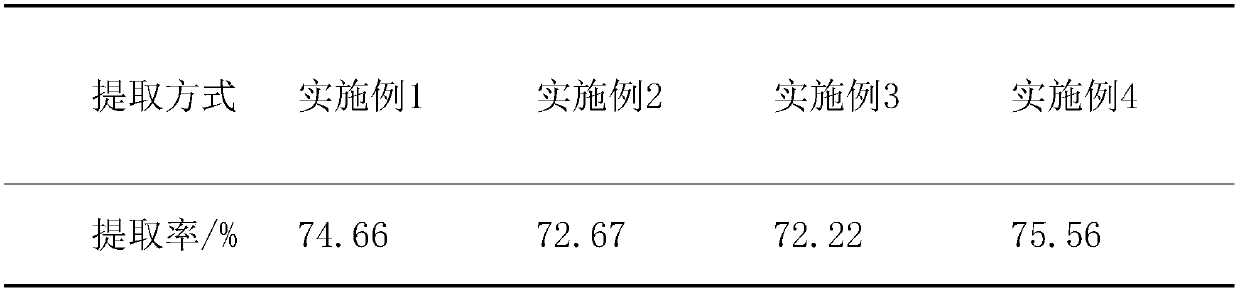

Examples

Embodiment 1

[0038] A process for extracting hijiki polysaccharides, the specific method steps are as follows:

[0039] (1) Pour 3000kg of water into the No. 1 multifunctional extraction tank and adjust the temperature to 90℃;

[0040] (2) Add 300kg of hijiki raw material to the No. 3 multifunctional extraction tank, start stirring and extraction, and the extraction time is 5 hours, during the process, keep the temperature between 85-90℃, the extraction is finished, sampling and testing the content of the extract;

[0041] (3) Discharge the extracted liquid in the No. 3 multifunctional extraction tank, pass through the vibrating screen, and enter the No. 2 multifunctional extraction tank. The temperature is maintained at 60-65℃, and the extracted liquid is 2200kg, which is 8 / 1000 by weight. Weigh cellulase;

[0042] (4) Add the cellulase directly to the No. 2 multifunctional extraction tank, stir for 30 minutes to dissolve it, then stir for 3-4 hours, and then let it stand for 14 hours for reactio...

Embodiment 2

[0051] A process for extracting hijiki polysaccharides, the specific method steps are as follows:

[0052] (1) Pour 3000kg of water into the No. 1 multifunctional extraction tank and adjust the temperature to 90℃;

[0053] (2) Add 300kg of hijiki raw material to the No. 3 multifunctional extraction tank, start stirring and extraction, and the extraction time is 5 hours, during the process, keep the temperature between 85-90℃, the extraction is finished, sampling and testing the content of the extract;

[0054] (3) Discharge the extracted liquid in the No. 3 multifunctional extraction tank, pass through the vibrating screen, and enter the No. 2 multifunctional extraction tank. The temperature is maintained at 60-65℃, and the extracted liquid is 2200kg, which is 8 / 1000 by weight. Weigh hemicellulase;

[0055] (4) Add the hemicellulase directly to the No. 2 multifunctional extraction tank, stir for 30 minutes to dissolve it, stir for 3-4 hours, and then let it stand for 14 hours to react...

Embodiment 3

[0064] A process for extracting hijiki polysaccharides, the specific method steps are as follows:

[0065] (1) Pour 3000kg of water into the No. 1 multifunctional extraction tank and adjust the temperature to 90℃;

[0066] (2) Add 300kg of hijiki raw material to the No. 3 multifunctional extraction tank, start stirring and extraction, and the extraction time is 5 hours, during the process, keep the temperature between 85-90℃, the extraction is finished, sampling and testing the content of the extract;

[0067] (3) Discharge the extracted liquid in the No. 3 multifunctional extraction tank, pass through the vibrating screen, and enter the No. 2 multifunctional extraction tank. The temperature is maintained at 60-65℃, and the extracted liquid is 2200kg, which is 8 / 1000 by weight. Weigh xylanase;

[0068] (4) Add xylanase directly to the No. 2 multifunctional extraction tank, stir for 30 minutes to dissolve it, then stir for 3-4 hours, and then let it stand for 14 hours to react. The enz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com