Microbial organic master batch and preparation method thereof

A technology of microorganisms and microbial inoculants, used in the chemical industry to enhance activity, increase fertilizer efficiency, and ensure healthy survival.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

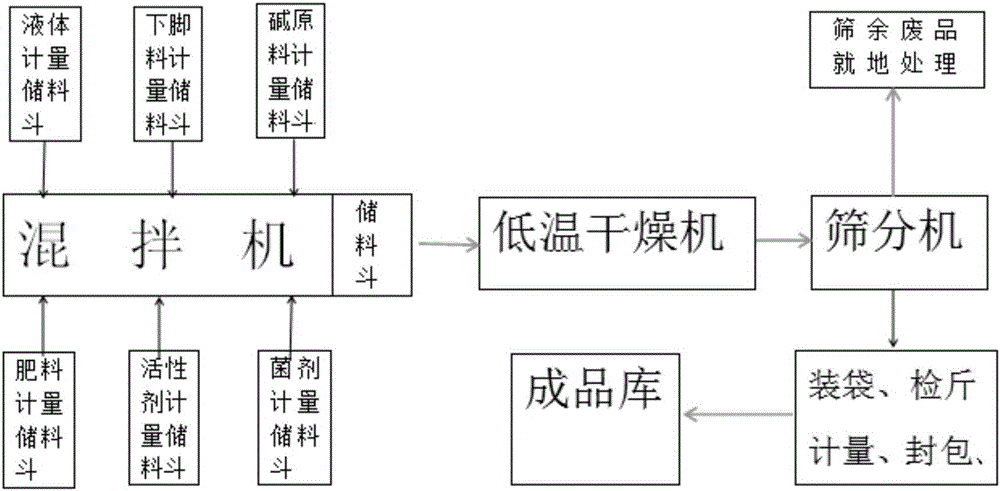

Method used

Image

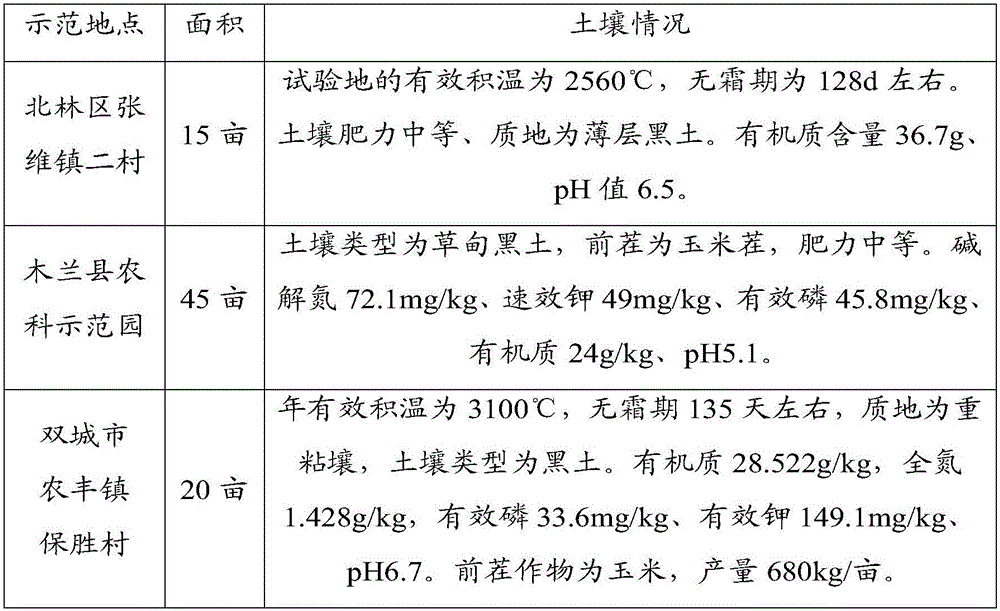

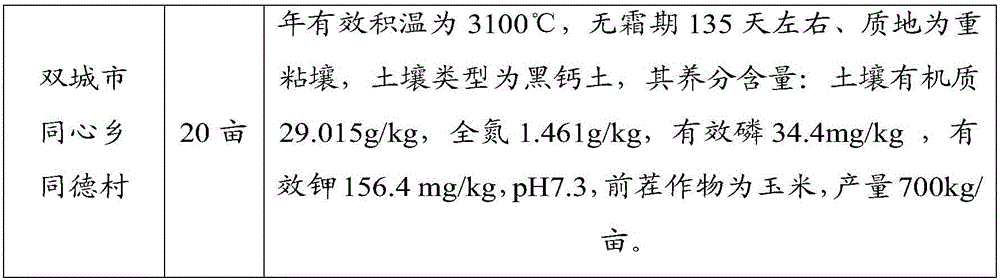

Examples

Embodiment 1

[0036] Prepare the microbial organic masterbatch according to the following steps

[0037] 1. Weigh 300 kilograms of monosodium glutamate leftovers, accounting for 70.26% of the total weight, and put them into the metering storage hopper for use.

[0038] 2. Weigh 35 kilograms of industrial sodium carbonate after pulverization, account for 8.20% of the total weight, and put it into a metering storage hopper for use.

[0039] 3. Weigh 30 kg of crushed urea, 10 kg of monoammonium phosphate, and 20 kg of potassium sulfate, accounting for 14.05% of the total weight, and put it into a metering storage hopper for use.

[0040] 4. Weigh 10 kilograms of ferric oxide, accounting for 2.34% of the total weight, and put it into the metering storage hopper for use.

[0041] 5. Take 100 billion Bacillus subtilis, Bacillus amyloliquefaciens, Bacillus colioids or 3 kg of bacteria mixture of Bacillus subtilis, Bacillus amyloliquefaciens and Bacillus colioids, account for 0.7% of the total wei...

Embodiment 2

[0046] Prepare the microbial organic masterbatch according to the following steps

[0047] 1. Weigh 450 kilograms of monosodium glutamate leftovers, accounting for 80.79% of the total weight, and put them into the metering storage hopper for later use.

[0048] 2. Weigh 10 kilograms of industrial potassium carbonate after crushing, account for 1.80% of the total weight, and put it into a metering storage hopper for use.

[0049] 3. Weigh 15 kg of crushed urea, accounting for 2.69% of the total weight, and put it into a metering storage hopper for use.

[0050] 4. Weigh 50 kilograms of ferric oxide, accounting for 8.98% of the total weight, and put it into a metering storage hopper for use.

[0051] 5. Weigh 20 kilograms of 100 billion Bacillus subtilis, accounting for 3.59% of the total weight, and put it into a metering storage hopper for use.

[0052] 6. Weigh 12 kg of urea saturated solution, accounting for 2.15% of the total weight, and put it into the metering storage t...

Embodiment 3

[0056] Prepare the microbial organic masterbatch according to the following steps

[0057] 1. Weigh 85 kilograms of monosodium glutamate leftovers, accounting for 85% of the total weight, and put them into the metering storage hopper for later use.

[0058] 2. Weigh 1 kg of carbon black, accounting for 1% of the total weight, and put it into a metering storage hopper for later use.

[0059] 3. Weigh 10 kg of Bacillus megaterium, accounting for 10% of the total weight, and put it into a metering storage hopper for use.

[0060] 4. Weigh 4 kg of urea saturated solution, accounting for 4% of the total weight, and put it into the metering storage tank for use.

[0061] Total: 100 kg

[0062] Put the leftovers into the mixer first, add 3 kg of saturated urea aqueous solution (accounting for 75% of the total saturated solution) to the material in the mixer continuously and evenly under the condition of constant stirring, and wait until the surface of the MSG leftovers is sprayed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com