Comprehensive utilization method for producing potassium sulfate and magnesium resources through magnesium sulfate conversion method

A technology of potassium sulfate and magnesium sulfate, applied in the field of salt chemical industry, can solve the problems of magnesium resource loss, potassium element loss, environmental pollution, etc., and achieve the effects of increasing potassium yield, eliminating pollution, and improving system economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

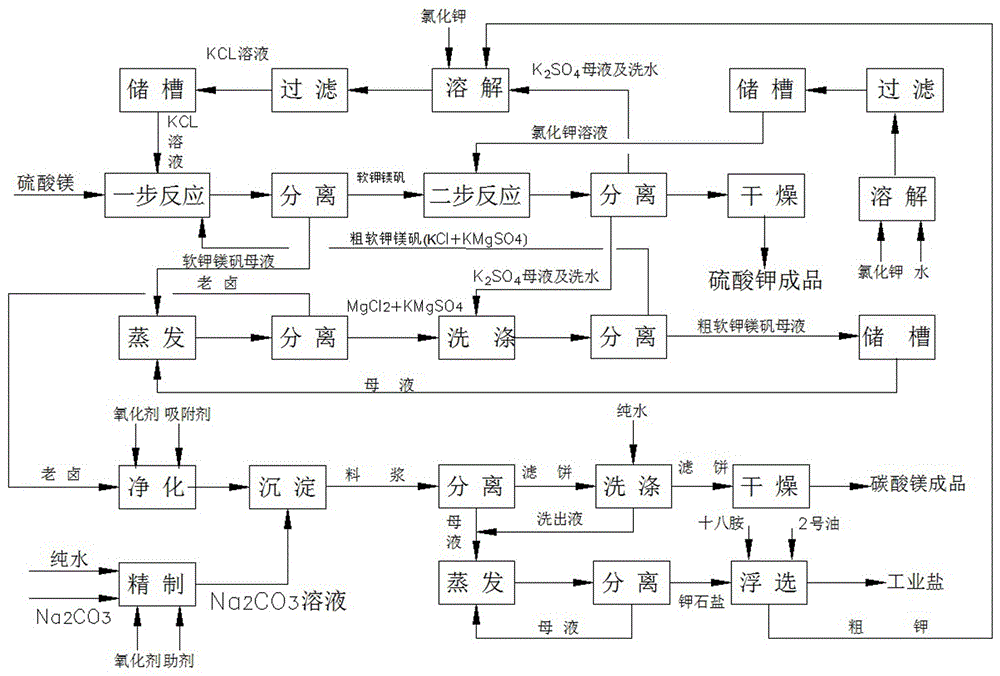

[0041] A comprehensive utilization method for producing potassium sulfate and magnesium resources by a magnesium sulfate conversion method, such as figure 1 shown, including the following steps:

[0042] Step 1: Add 20kg of crude potassium and 25.45kg of potassium chloride with a content of 83.59% to 298kg of potassium sulfate mother liquor and washing water, heat up to 60°C and dissolve completely, then filter to remove water insolubles to obtain potassium chloride solution.

[0043] Then the potassium chloride solution is sent into a one-step reaction process, 222kg of magnesium sulfate heptahydrate and 83kg of coarse langinite are added under stirring conditions, separated after reacting at 60°C for 120min, washed with an appropriate amount of water, and 225kg of langbeinite and zoleinite are obtained. Magneite mother liquor 425kg.

[0044] Step 2: send 425kg langbeinite mother liquor and 139kg coarse langbeinite mother liquor to the evaporating salt field, use natural con...

Embodiment 2

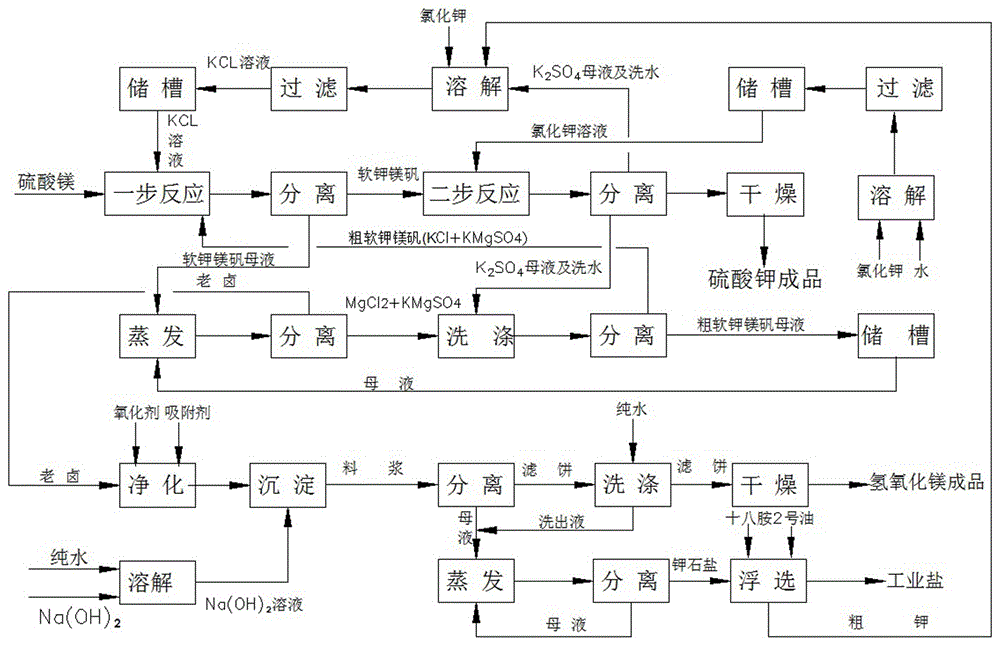

[0053] A comprehensive utilization method for producing potassium sulfate and magnesium resources by a magnesium sulfate conversion method, such as figure 2 shown, including the following steps:

[0054] Step 1: Add 210kg of crude potassium and 170Kg of potassium chloride (containing 90% KCl) to 2160kg of potassium sulfate mother liquor and washing water, heat up to 80°C and dissolve completely, then filter to remove water-insoluble matter to obtain potassium chloride solution.

[0055] Then the potassium chloride solution is sent into a one-step reaction process, 1540kg of magnesium sulfate heptahydrate and 470kg of coarse langinite are added under stirring conditions, separated after reacting at 80°C for 120min, washed with an appropriate amount of water, and 1560kg of langinite and leninite are obtained. Magnesite mother liquor 2990kg.

[0056] Step 2: Send 2990kg of langbeinite mother liquor and 1070kg of coarse langbeinite mother liquor to the evaporation salt field, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com