Material tank for producing steel and iron

A material and steel technology, applied in the field of iron and steel material transfer, can solve the problems of personal safety threats of ground personnel, long unloading time, low unloading accuracy, etc., and achieve the effect of convenient transfer and unloading, and convenient loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

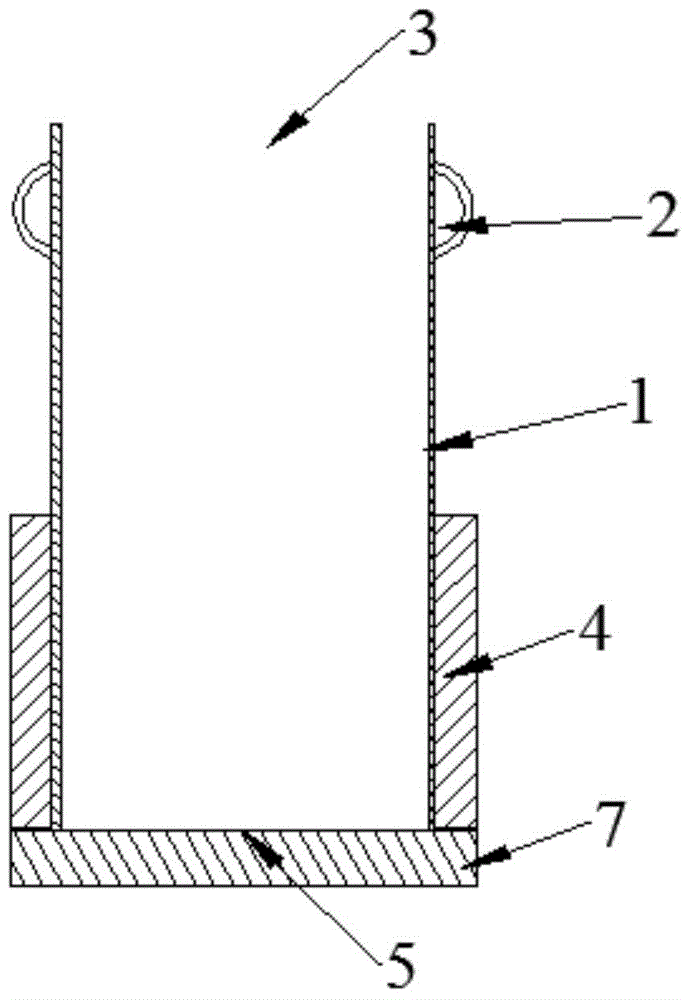

[0017] Embodiment 1 of the present invention provides a kind of material tank for producing iron and steel, such as figure 1 As shown, it includes a tank body 1, a hook 2 arranged on the tank body 1, a feed inlet 3 arranged at the top of the tank body 1, and a discharge port 5 arranged at the bottom of the tank body 1, and the outside of the bottom side wall of the tank body 1 An electromagnetic relay 4 is provided, and a cover 7 matching the discharge port 7 is provided at the bottom of the tank body 1. The cover body 7 is hinged to the tank body 1, and the cover body 7 is magnetic.

Embodiment 2

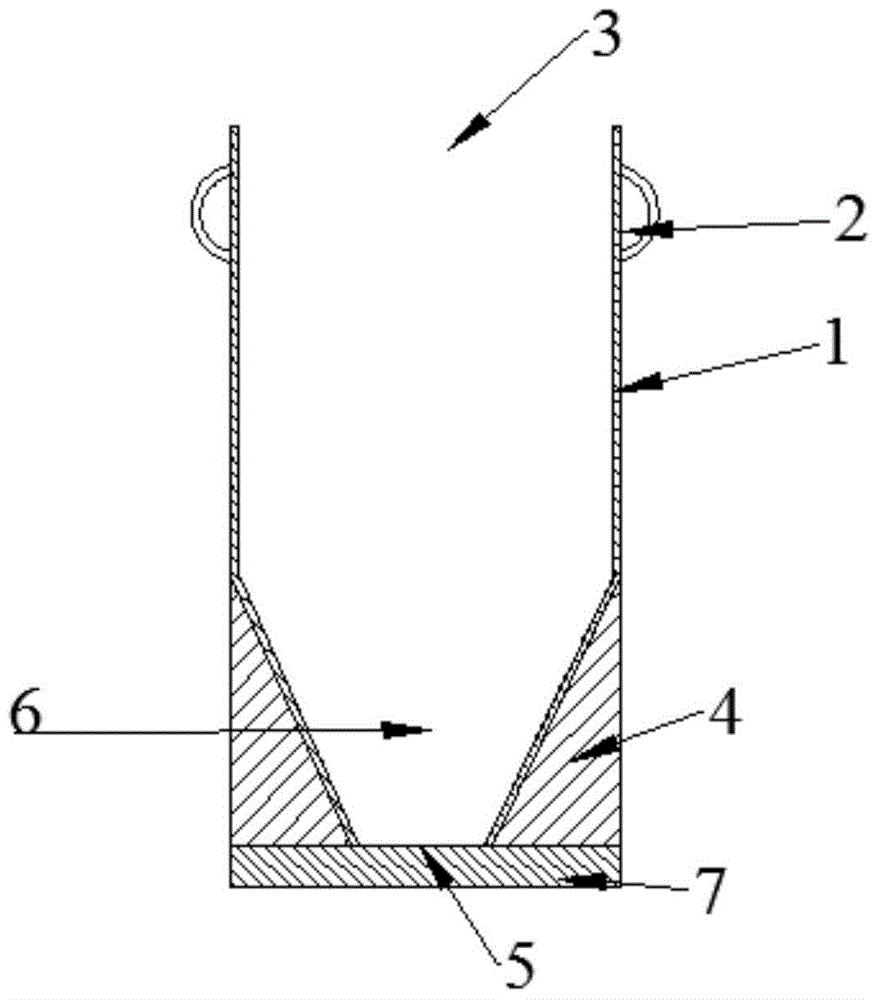

[0019] Embodiment 2 of the present invention provides a kind of material tank for producing iron and steel, such as figure 2 As shown, it includes a tank body 1, a hook 2 arranged on the tank body 1, a feed inlet 3 arranged at the top of the tank body 1, and a discharge port 5 arranged at the bottom of the tank body 1, and the outside of the bottom side wall of the tank body 1 An electromagnetic relay 4 is provided, and the bottom end of the tank body 1 is provided with a cover body 7 matched with the discharge port 7, the cover body 7 is hinged with the tank body 1, and the cover body 7 is magnetic. The cross-section is a trapezoid with a wide upper side and a narrower lower side. The switch of the electromagnetic relay 4 is a remote control switch, and there are two hooks 2, which are arranged symmetrically.

[0020] Realize the working process of embodiment 1 and embodiment 2: when charging is required, the switch of electromagnetic relay 4 is opened, and the cover body 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com