Microcellular foam thermoplastic polyurethane material and preparation method thereof

A thermoplastic polyurethane and microcellular foaming technology, which is applied in the field of polymer foaming material preparation, can solve the problems of accelerating product aging speed, affecting product precision, product rupture, etc., achieving adjustable elastic strength, ensuring uniformity of pressure, The effect of good cushioning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

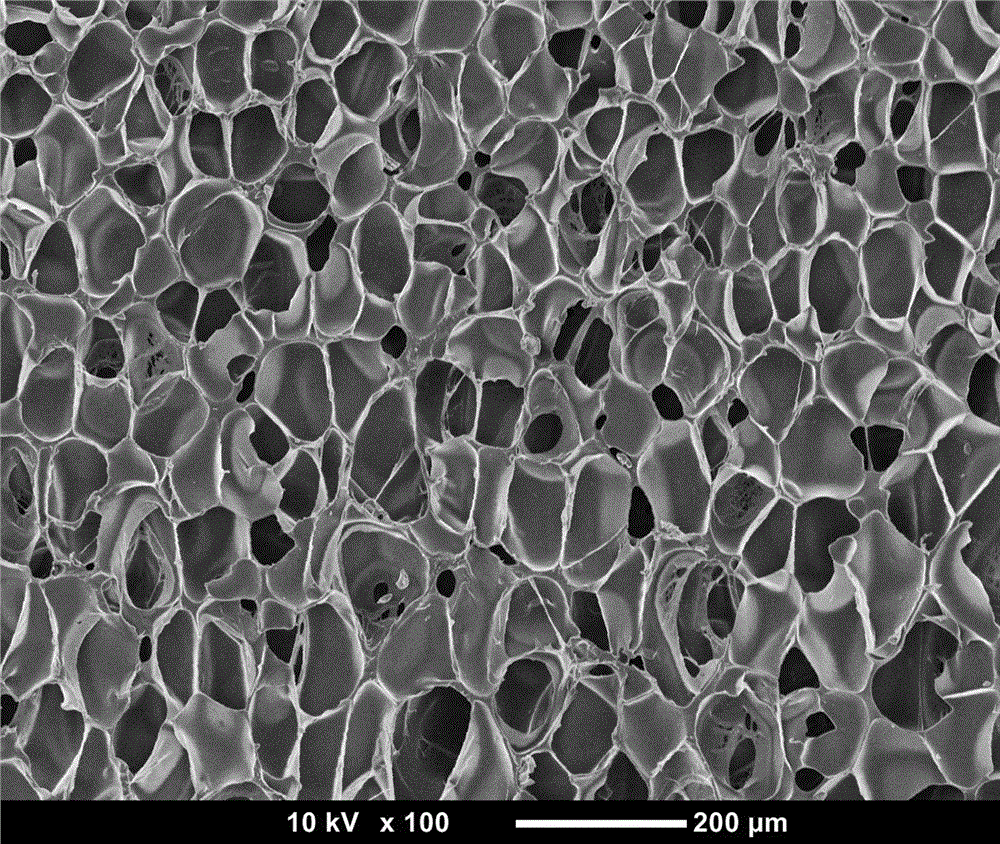

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing a microcellular foamed thermoplastic polyurethane material, and the specific steps include:

[0032] (1) Use an injection molding machine to heat-melt 1000g of thermoplastic polyurethane granules to obtain a thermoplastic polyurethane sol; control the temperature of the barrel of the injection molding machine from the side of the hopper to the position of the nozzle to gradually rise in the temperature range of 160°C to 220°C High, so that the temperature of thermoplastic polyurethane particles rises steadily to achieve the purpose of uniform plasticization.

[0033] (2) Continuously introduce carbon dioxide supercritical foaming gas with a gas pressure of 4MPa into the thermoplastic polyurethane sol at a gas introduction speed of 40ccm / s for a duration of 2s, and use the injection molding machine for mixing to obtain a mixed gas Sol.

[0034] (3) When the temperature of the controllable molding mold is 20°C, inject the m...

Embodiment 2

[0037] This embodiment provides a method for preparing a microcellular foamed thermoplastic polyurethane material, and the specific steps include:

[0038](1) Use an injection molding machine to heat-melt 1000g of thermoplastic polyurethane particles to obtain a thermoplastic polyurethane sol; control the temperature of the barrel of the injection molding machine from the side of the hopper to the position of the nozzle to gradually rise in the temperature range of 180°C~220°C High, so that the temperature of thermoplastic polyurethane particles rises steadily to achieve the purpose of uniform plasticization.

[0039] (2) Continuously introduce nitrogen supercritical foaming gas with a gas pressure of 15MPa into the thermoplastic polyurethane sol at a gas introduction speed of 80ccm / s for a duration of 1s, and use the injection molding machine for mixing to obtain a mixed gas Sol.

[0040] (3) When the temperature of the controllable molding mold is 65°C, the mass of the mixe...

Embodiment 3

[0043] This embodiment provides a method for preparing a microcellular foamed thermoplastic polyurethane material, and the specific steps include:

[0044] (1) Use an injection molding machine to heat-melt 1000g of thermoplastic polyurethane particles to obtain a thermoplastic polyurethane sol; control the temperature of the barrel of the injection molding machine from the side of the hopper to the position of the nozzle to gradually rise in the temperature range of 160°C~210°C High, so that the temperature of thermoplastic polyurethane particles rises steadily to achieve the purpose of uniform plasticization.

[0045] (2) Continuously introduce a supercritical foaming gas composed of a mixture of carbon dioxide and nitrogen at a gas pressure of 23MPa into the thermoplastic polyurethane sol at a gas introduction rate of 50ccm / s for a duration of 0.5s, and use the injection molding machine to carry out Mixing to obtain a mixed aerosol.

[0046] (3) Control the temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com