Flexible automatic production line and method used for machining car engine cylinder cover

An automobile engine and flexible production technology, which is applied in metal processing, manufacturing tools, and other manufacturing equipment/tools, can solve problems such as low efficiency, long processing procedures, and waste of manpower, so as to improve response speed, increase utilization rate, reduce The effect of labor expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

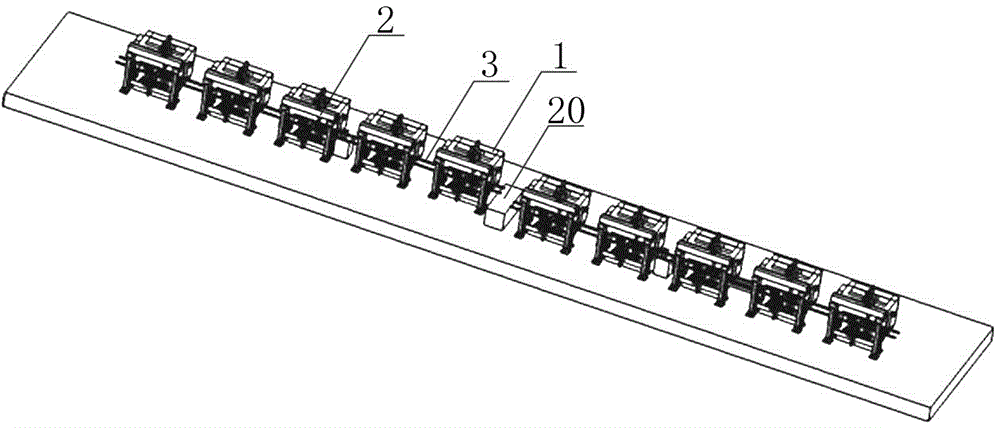

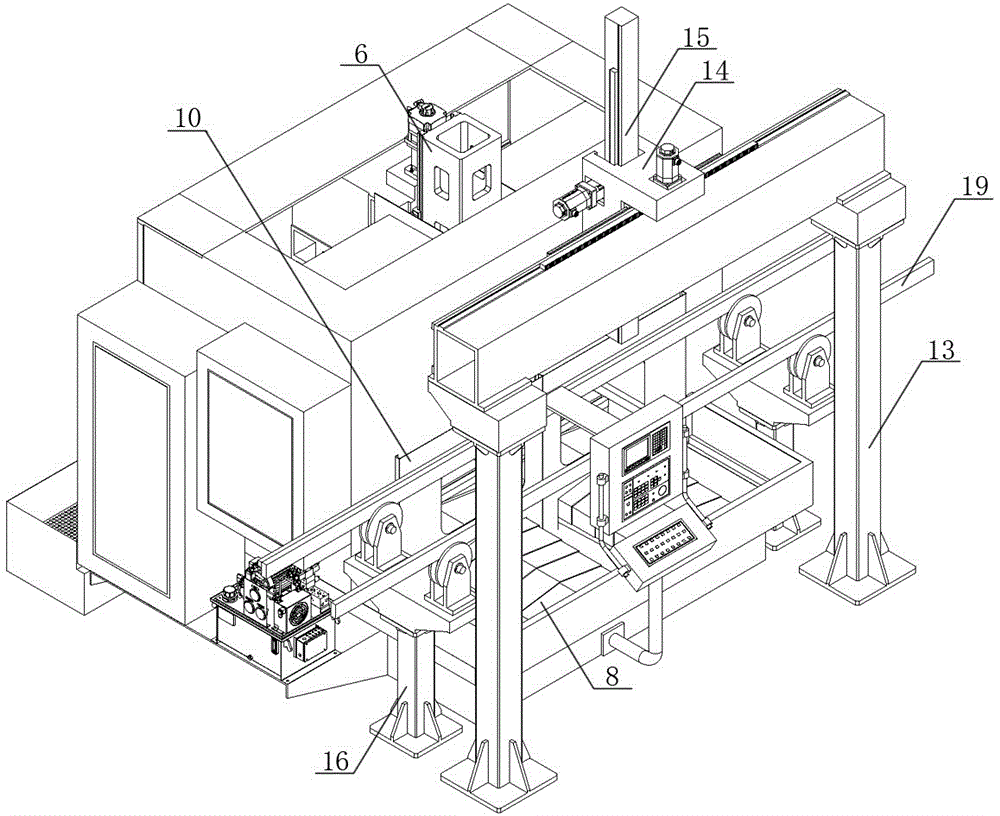

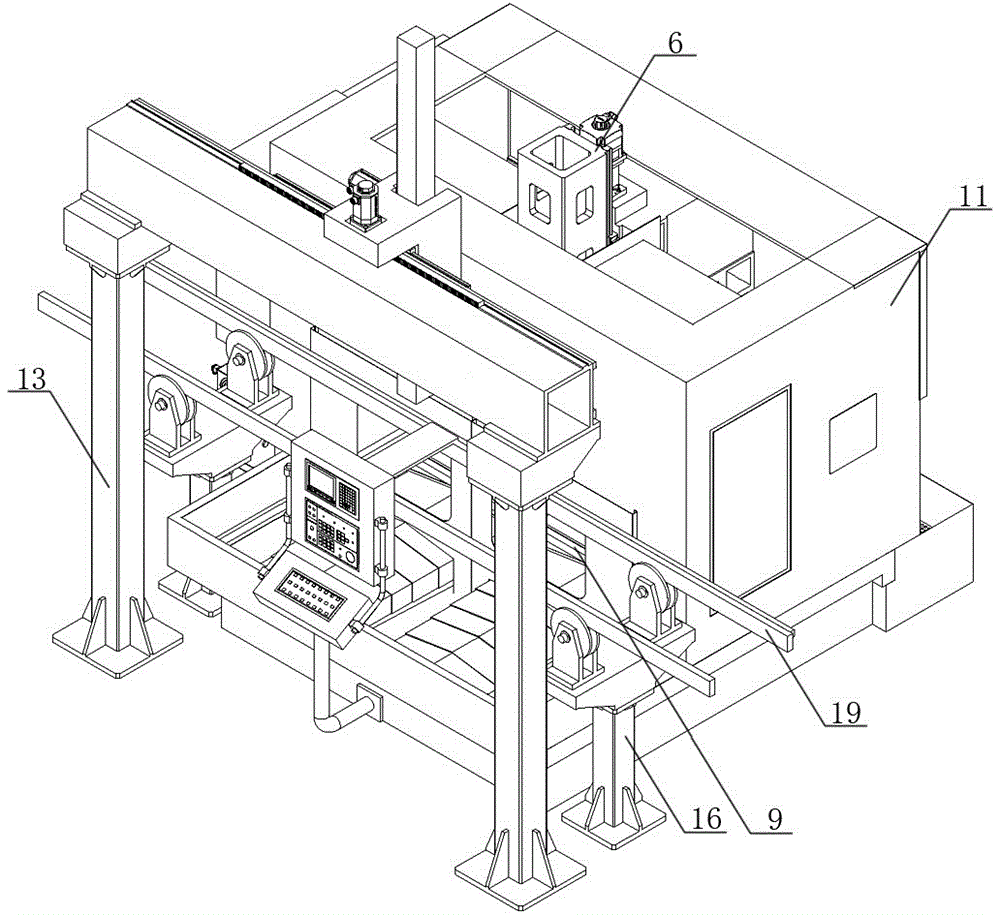

[0065] Examples see figure 1 As shown, this flexible automatic production line for processing automobile engine cylinder heads includes a row of machine tools arranged at intervals, and also includes a truss manipulator 2 and a material transportation system 3; the truss manipulator 2 corresponds to the machine tool 1 one by one and is set In front of the machine tool; the conveyor belt 19 of the material transport system 3 spans the front end of a row of machine tools, and extends continuously from the first machine tool to the last machine tool, and the conveyor belt 19 is evenly spaced and connected with horizontal Tooling board 18. In this example, the production automatic line includes 10 machine tools. The front 5 machines are counted as a group, and the rear 5 machines are counted as a group. The conveyor belt between each group of machine tools is continuous, and the conveyor belt between the two groups passes through a The slide table 20 is connected as a whole, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com