Brush roller with double bearing pedestals

A technology of double bearings and moving bearing seats, which is applied to the cleaning method using tools, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of unusable, cost waste, and insufficient extrusion, so as to improve the service life , cost reduction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

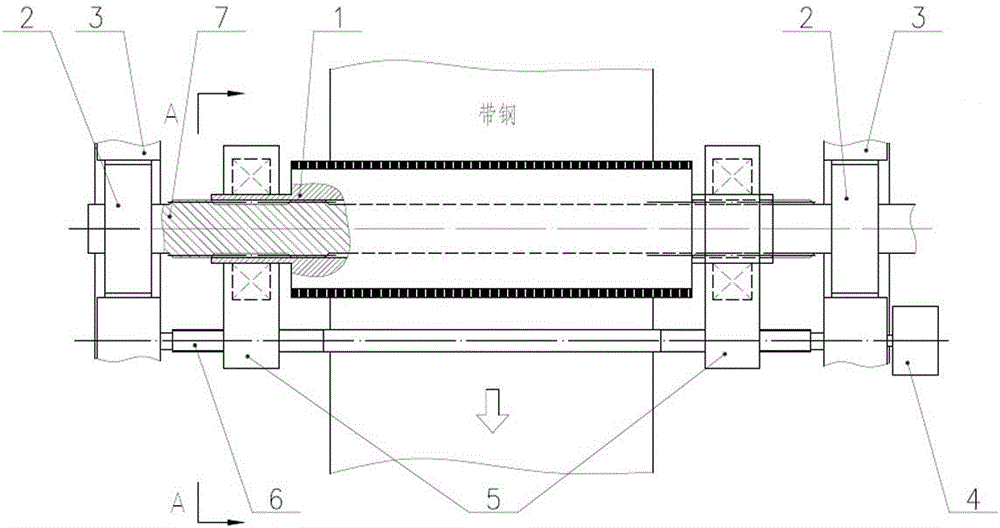

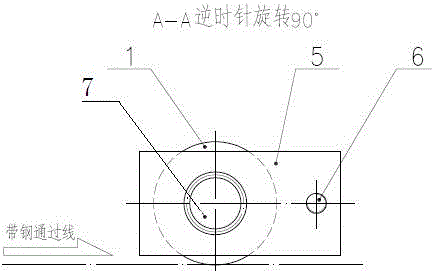

[0016] Such as figure 1 As shown, a brush roller with a double bearing seat includes a brush roller shaft 7 and a brush roller 1, the brush roller 1 is provided with bristles, and the brush roller 1 is set on the brush roller shaft 7 and passes through the splines The two ends of the brush roller shaft 7 pass through the brush roller 1 respectively and are respectively arranged on a fixed bearing seat 2. The two fixed bearing seats 2 are respectively arranged on a frame 3. The two ends of the brush roller 1 Each is arranged on a movable bearing seat 5, and a lead screw 6 respectively fits through the two movable bearing seats 5 and is parallel to the brush roller shaft 7. One end of the lead screw 6 is arranged on a frame 3, and the other end passes through the The other frame 3 is also connected with the driving mechanism 4, and the driving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com