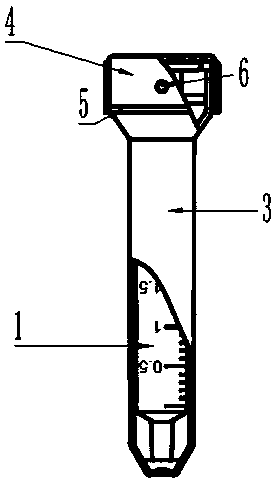

A kind of assembly method of sheath syringe

An assembly method and a syringe technology, which are applied in the medical field, can solve the problems of inability to realize large-scale continuous production of products, low degree of mechanization, poor interchangeability, etc., and achieve the effects of high yield, good sealing effect and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

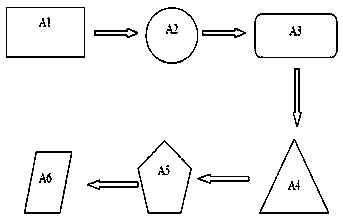

[0039] The invention provides a method for assembling a sheathed syringe, comprising the following steps:

[0040] Assembly of rubber plug and push rod: Send the push rod and rubber plug to a fixed position through the feeding device, and insert the push rod into the rubber plug by rotating the vertical drop;

[0041] A2. Assembling the barrel: assemble the push rod through rotation and the position of the turntable, and then transfer to the next process through the turntable;

[0042] A3. Sheath assembly: Turn the assembled cylinder to the upper and lower overlaps of the sheath through the turntable, the cylinder falls into the sheath, and transfer to the next process through the turntable;

[0043] A4. Cover assembly: turn the product on the upper turntable to a fixed position and cover the cover;

[0044] A5. Welding: transfer the product to the welding part through the chute or through the product flow channel, and weld the protective cover with the welding head, so that ...

Embodiment 2

[0054] The difference is that the ball milling time is 20 hours, the temperature of the entire production environment is 22°C, and the humidity is 55%.

Embodiment 3

[0056] The difference is that the ball milling time is 25 hours, the temperature of the entire production environment is 28°C, and the humidity is 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com