A tissue culture chamber that can precisely control temperature, humidity and light intensity

A technology of precise control and light intensity, applied in non-electric variable control, control/regulation systems, and simultaneous control of multiple variables, etc., can solve the problem that the tissue culture room cannot accurately control the indoor temperature, humidity and light intensity, affecting plant growth, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

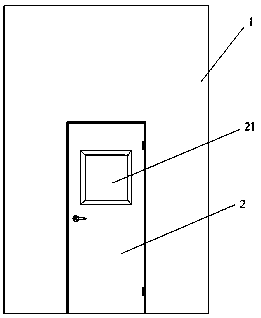

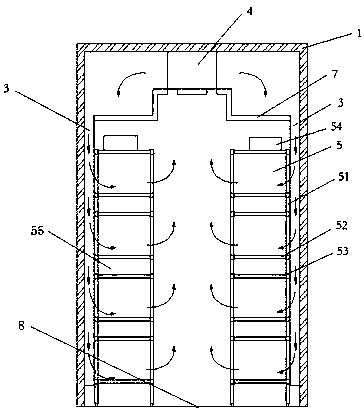

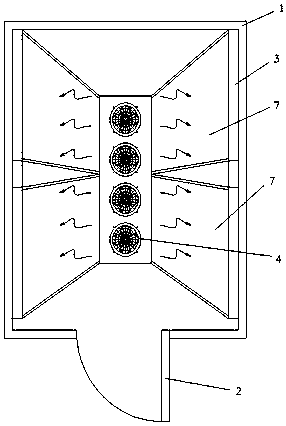

[0035] Such as figure 1 Shown in -5, it is a kind of temperature and humidity controllable tissue culture chamber of the present invention, comprising:

[0036] Chamber body 1, the surface of the chamber body is steel plate, and the interlayer is polyurethane. The polyurethane interlayer can improve the thermal insulation performance of the tissue culture room. The chamber body is spliced by 5 polyurethane boards whose surfaces are steel plates and the interlayer is polyurethane. The polyurethane boards are connected by eccentric hooks. The polyurethane joints on the top are all spliced at a 45°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com