Integrated antenna feed system quality degree measuring method

An antenna system and quality technology, applied in the field of quality evaluation of complex phased array antenna equipment, can solve problems such as numerous indicators, complex structure and functions of antenna equipment, difficult to be accurate, fast, economical, and reasonable evaluation objects, etc. , to achieve the effect of improving objectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

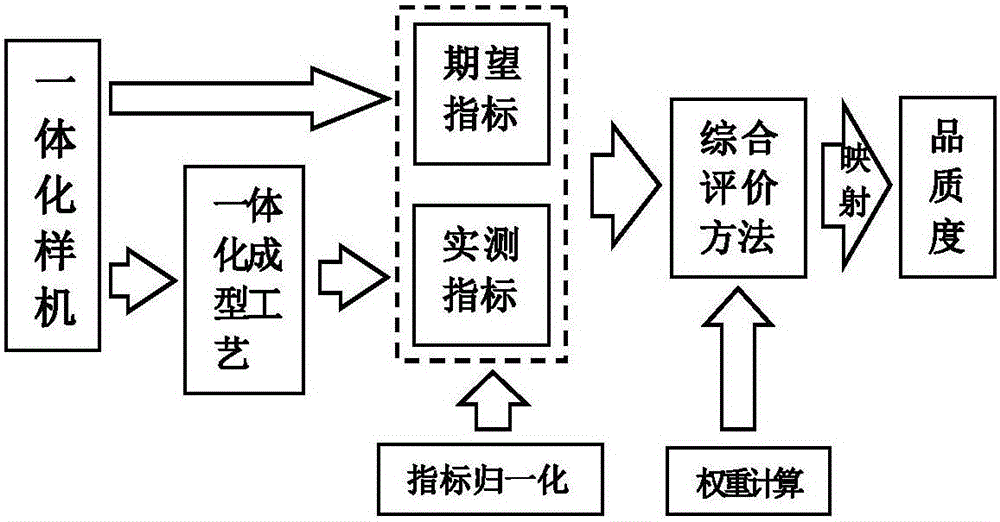

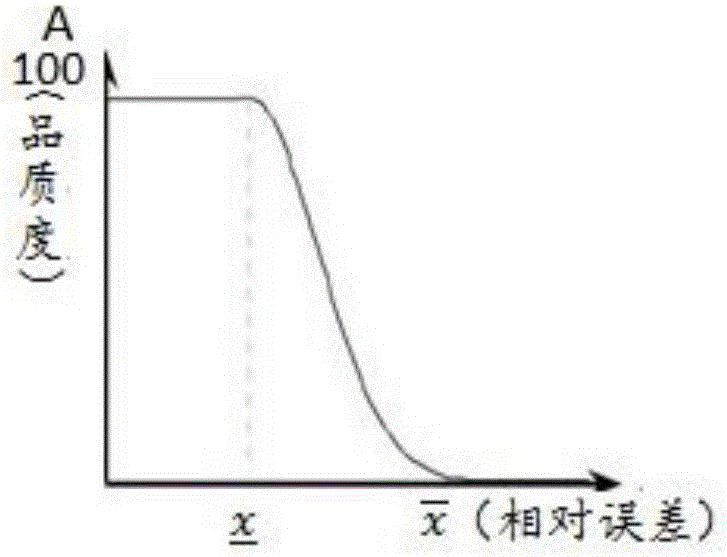

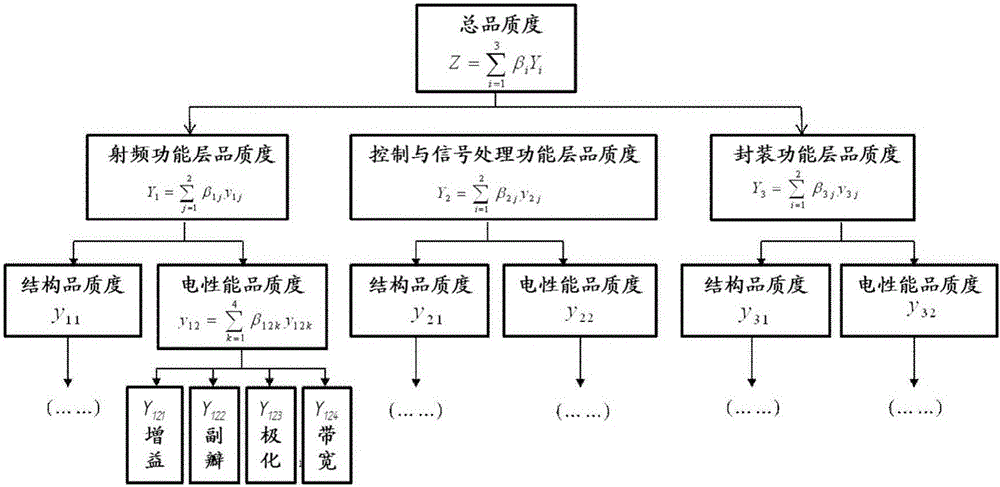

[0014] Refer to figure 1 . In the embodiments described below, according to the present invention, the integrated antenna feed system product is first divided into functional layers or component modules according to its composition, and the technical indicators characterizing its functional performance characteristics are listed separately to establish an integrated antenna Feed system quality evaluation system model; then for each index, compare the expected index of each index and the actual measured index formed by the integrated process, according to the index normalization, data mapping transformation processing method, and use specific conversion procedures for different metadata elements Format conversion, the difference between the expected value of each indicator and the measured value is converted into the single indicator quality of the functional layer or module; according to the indicator weight calculation method, the fuzzy consistent judgment matrix R is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com