Experiment device and method used for detecting bonding strength of channeling sealing agent

A technology of cementation strength and experimental device, which is applied in the field of testing the cementation strength of sealing agent and the field of experimental device for detecting the cementation strength of sealing agent, can solve the problems of inconvenient operation, high temperature and high pressure danger, complex structure, etc., and achieve convenient operation and detection Fast, data-accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

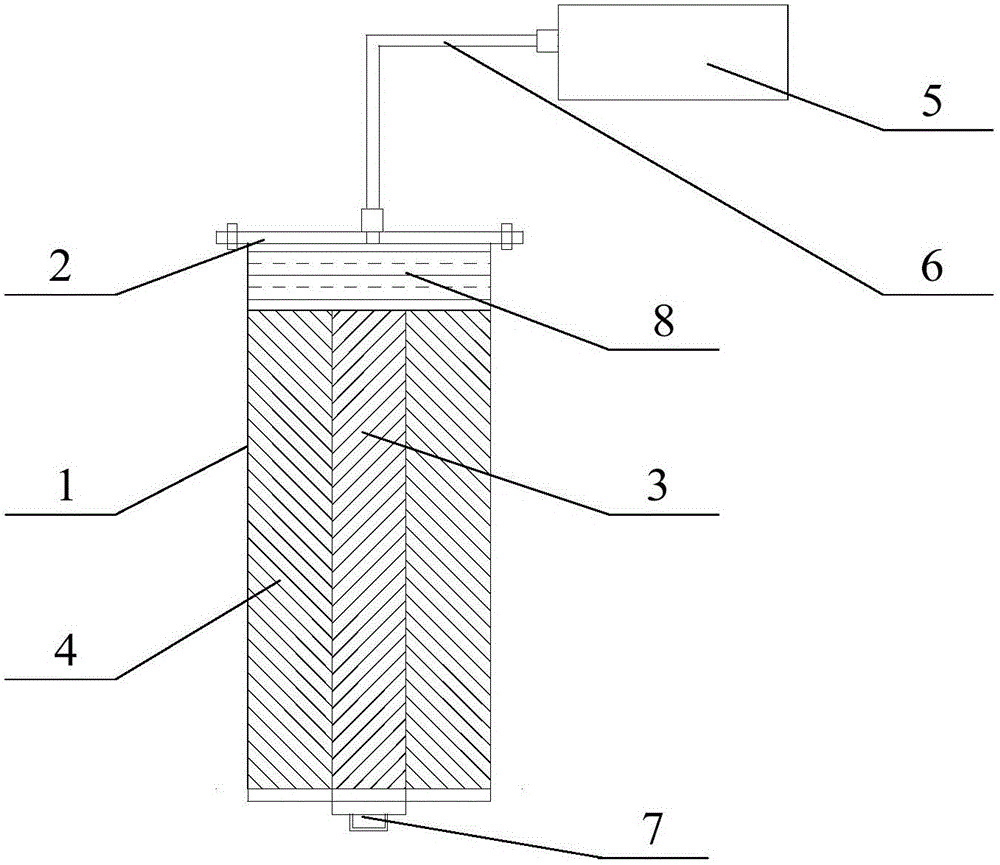

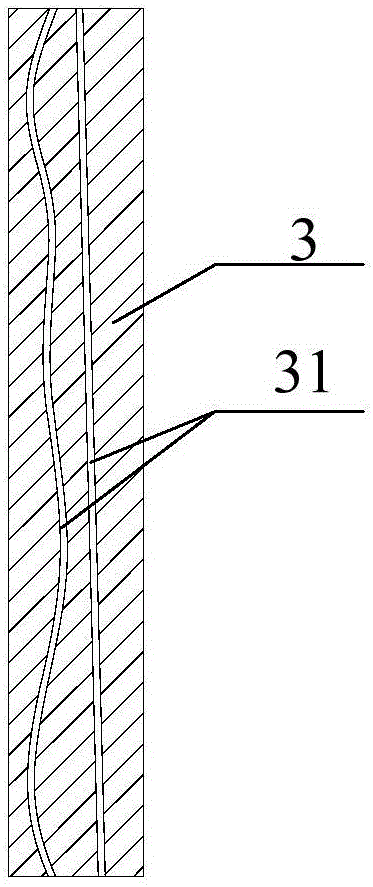

[0037] Such as figure 1 As shown, the present invention provides an experimental device for testing the cementation strength of the blocking agent, which includes: a sleeve 1 and a fluid pumping mechanism 5, wherein the sleeve 1 is a hollow shell with a closed bottom and an open top body, the bottom end of casing 1 is provided with a liquid outlet, the top of casing 1 is connected with flange cover 2, and flange cover 2 is provided with a liquid inlet, and the center of casing 1 is provided with an artificial core 3, such as figure 2 As shown, the artificial core 3 has a plurality of cracks 31 arranged from top to bottom and capable of containing the channeling agent to simulate the cracks of annular cement, such as figure 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com