Electromagnetic piling device and piling method

A piling device and electromagnetic technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of high noise self-weight and soil layer requirements, and achieve the effects of fast piling speed, reduced equipment weight, and high piling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

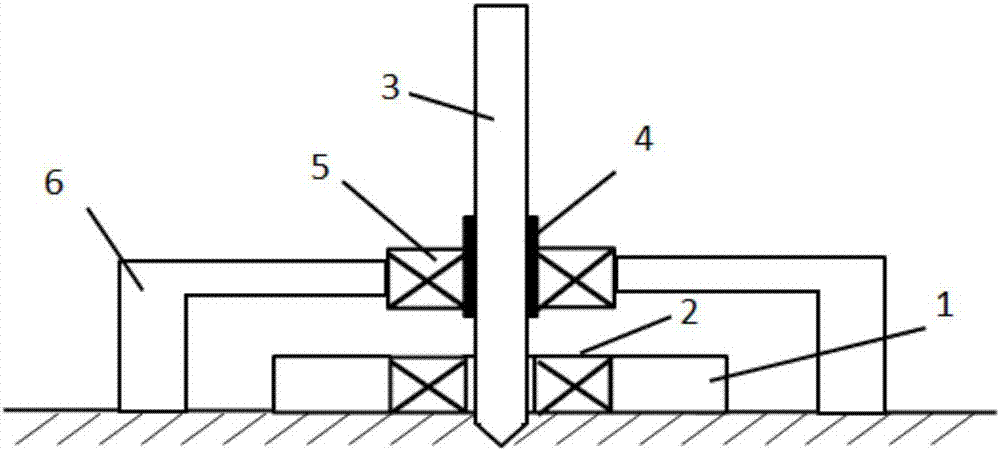

[0039] Such as figure 1 As shown, the overall structure of the electromagnetic piling in the embodiment of the present invention includes: a base 1 , a ground coil set 2 , a pile body 3 , a clamping mechanism 4 , a pile body coil set 5 , and a bracket 6 .

[0040] The base is arranged on the ground for installing the ground coil group and supporting the clamping mechanism; there is a pile hole in the middle of the base, and a groove is provided on the outer edge of the pile hole, and the ground coil group is installed in the groove (see Figure 6 ); the clamping mechanism is fixed on the base or the ground through a bracket; the clamping mechanism is used to clamp or release the pile body; The outside of the mechanism is arranged coaxially with the ground coil group, and the distance is relatively close to ensure sufficient electromagnetic force between the two coil groups.

[0041] The electromagnetic piling method includes the following steps:

[0042] (1) Fix the ground c...

Embodiment 2

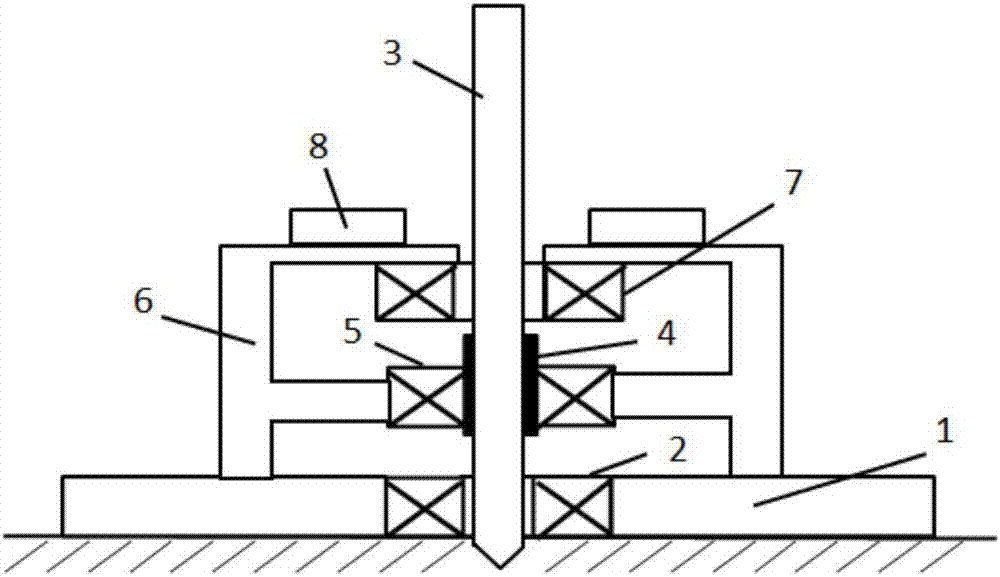

[0051] Such as figure 2 As shown, the overall structure of the electromagnetic piling of the embodiment of the present invention includes: a base 1, a ground coil group 2, a pile body 3, a clamping mechanism 4, a pile body coil group 5, a bracket 6, a first auxiliary coil group 7, and Weight 8.

[0052] The electromagnetic piling method includes the following steps:

[0053] (1) Fix the ground coil set 2 on the base 1 by bolts.

[0054] (2) The first auxiliary coil group 7 is fixed on the stand 6 by bolts, and the counterweight 8 is installed on the support 6 .

[0055] (3) Pass the pile body 3 through the first auxiliary coil group 7 and place it in the aperture of the coil group 7 .

[0056] (4) Hold the clamping mechanism 4 tightly to the pile body 3 , and the pile body coil group 5 is fastened to the pile body 3 through the clamping mechanism 4 .

[0057] (5) The clamping mechanism 4 realizes its own free movement up and down through the guide rail on the bracket 6 . ...

Embodiment 3

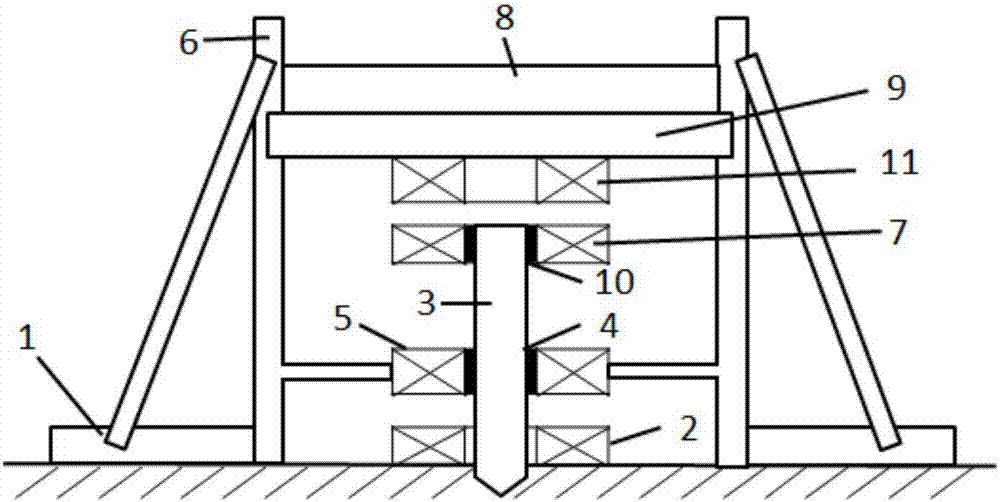

[0064] Such as image 3 As shown, the overall structure of the electromagnetic piling of the embodiment of the present invention includes: a base 1, a ground coil group 2, a pile body 3, a clamping mechanism 4, a pile body coil group 5, a bracket 6, a first auxiliary coil group 7, and Weight 8, top plate 9, second clamping mechanism 10, second auxiliary coil group 11.

[0065] The electromagnetic piling method includes the following steps:

[0066] (1) Fasten the first auxiliary coil group 7 to the pile body 3 through the second clamping mechanism 10 .

[0067] (2) Adjust the second auxiliary coil set 11 directly above the first auxiliary coil set 7 through the top plate 9 and the bracket 6 , and the top plate 9 is used to fix the second auxiliary coil set 11 .

[0068] (3) After the position adjustment of the second auxiliary coil group 11 is completed, the counterweight 8 is placed on the top plate 9 .

[0069] (4) In the piling process, the second auxiliary coil group 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com