Horizontal pulled gate bottom trolley with rolling wheels of self-lubricating bearing structure

A technology of self-lubricating bearings and horizontal pull gates, which is applied in ship locks, ship lifting devices, buildings, etc., can solve problems such as rolling bearing failure, and achieve the effects of reduced production costs, saving replacement and maintenance costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples.

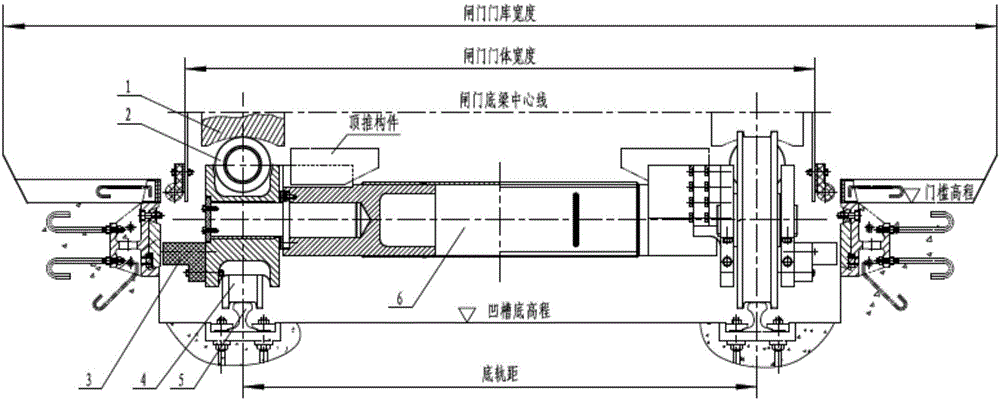

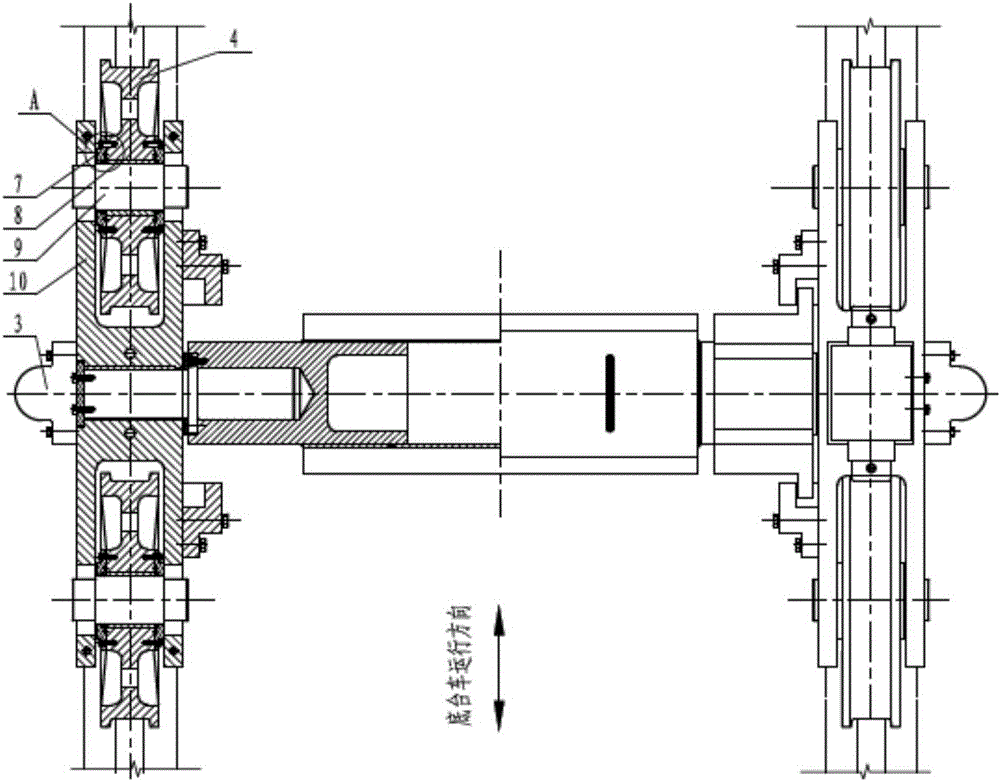

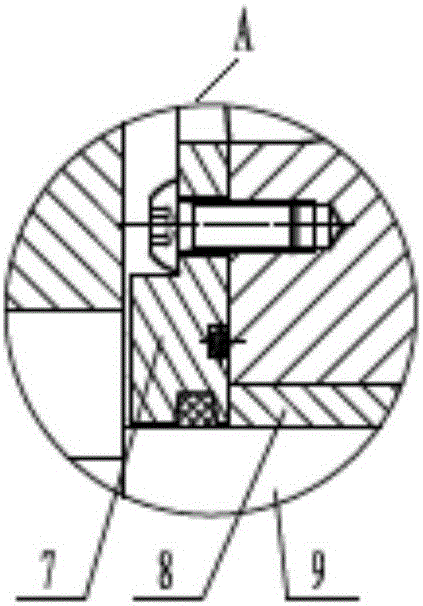

[0018] Such as Figure 1-Figure 3 As shown, it is a horizontal pull gate bottom trolley with self-lubricating bearing structure for the rollers, including four sets of roller parts, frame 10, frame beam 6 and roller parts 2, and each two groups of roller parts are installed on one frame 10, the two left and right frames are connected by the frame beam 6 to form the overall frame of the bottom trolley; the door body is located on the roller part 2 of the bottom trolley through the arc-shaped seat plate 1, and moves laterally through the roller part 2 under the water pressure After finishing close to the water stop, the left and right roller parts respectively walk along the bottom rail 5 laid in parallel in the groove below the threshold, so that the door body can walk back and forth along the bottom rail to complete the opening and closing;

[0019] Four groups of roller part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com