Glass fiber reinforced plastic ship bilge keel installation method

An installation method, the technology of FRP boats, applied in the field of ships, can solve the problems of inaccurate installation, poor installation accuracy, and difficult alignment, etc., and achieve the effects of high connection strength, good use effect, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

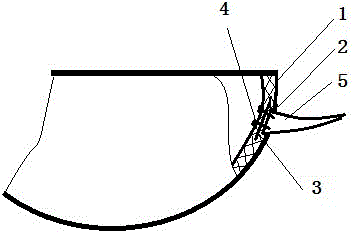

[0017] Combine below figure 1 The present invention is described further:

[0018] A method for installing a bilge keel of a glass-steel ship, characterized in that the steps are as follows:

[0019] Step 1. Set the groove (or boss) of the horizontal mark on the hull mold, and set the boss at the installation position of the bilge keel with the same shape as the installation surface of the bilge keel. The position adjustment of the bilge keel,

[0020] Step 2, prefabricate the hull, and install steel plates at the installation position of the bilge keel, the steel plates are clamped in the prefabricated FRP hull,

[0021] Step 3, prefabricating the bilge keel, the connecting end surface of the bilge keel is provided with a connecting steel plate to facilitate the connection with the hull,

[0022] Step 4, demoulding, install the bilge keel in the bilge keel installation groove on the hull, adjust the position of the bilge keel according to the convex (or concave) line of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com