Machining method of machine case of ultra-heavy and ultra-large-size type compressor

A processing method and compressor technology, applied in the field of air compressors, can solve the problems that the accuracy of the sealing ring and the central processing casing cannot be guaranteed, the processing size of the centrifugal section casing cannot be guaranteed, and the accuracy of the central processing casing cannot be guaranteed. To achieve the effect of guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

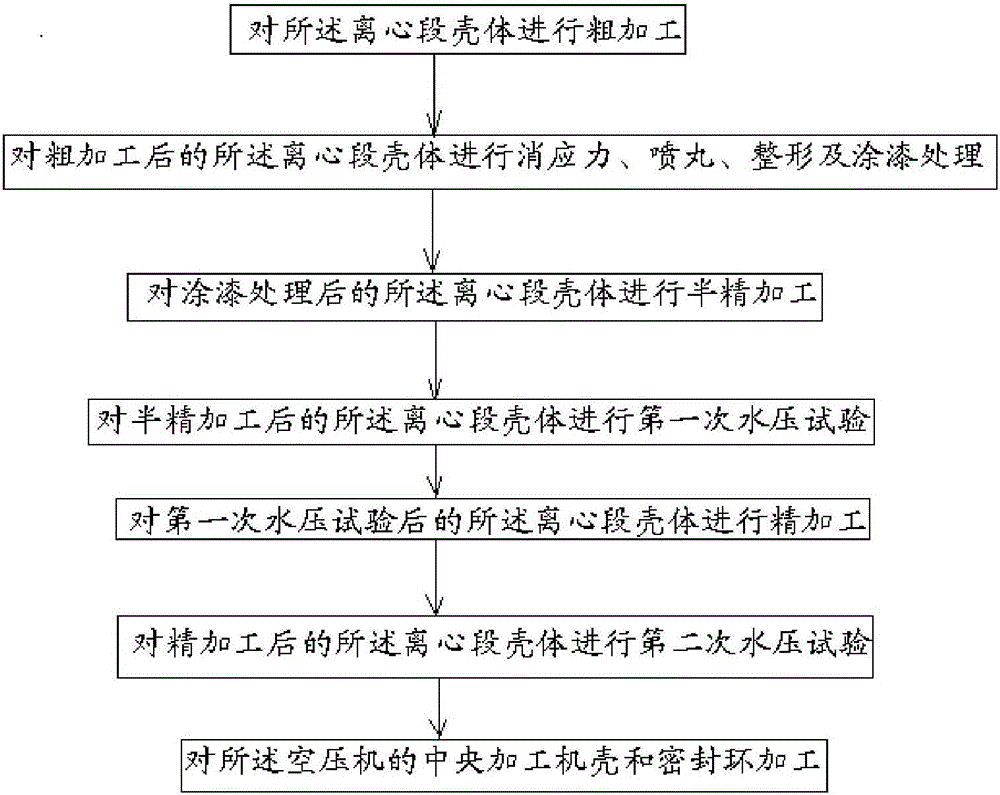

[0021] see figure 1 , the processing method of the super-heavy and super-large compressor casing provided by the embodiment of the present invention includes the following steps:

[0022] Step 1, processing the casing of the centrifugal section of the air compressor;

[0023] Among them, the processing of the shell of the centrifugal section of the air compressor includes:

[0024] Carry out rough machining on the centrifugal section casing, the rough machining includes: first scribing the centrifugal section casing of the air compressor through gantry milling, in order to ensure the accuracy of the inlet guide vane flow path and the compressor unit In the first scribing process, the end surface of the inlet guide vane must be used as a reference basis. The scribing process draws the horizontal mid-section processing lines of the upper and lower casings in the centrifugal section casing, and the entry and exit of the lower casing Tuyere flange plane processing line, outrigge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com